High recovery water treatment plant being commissioned

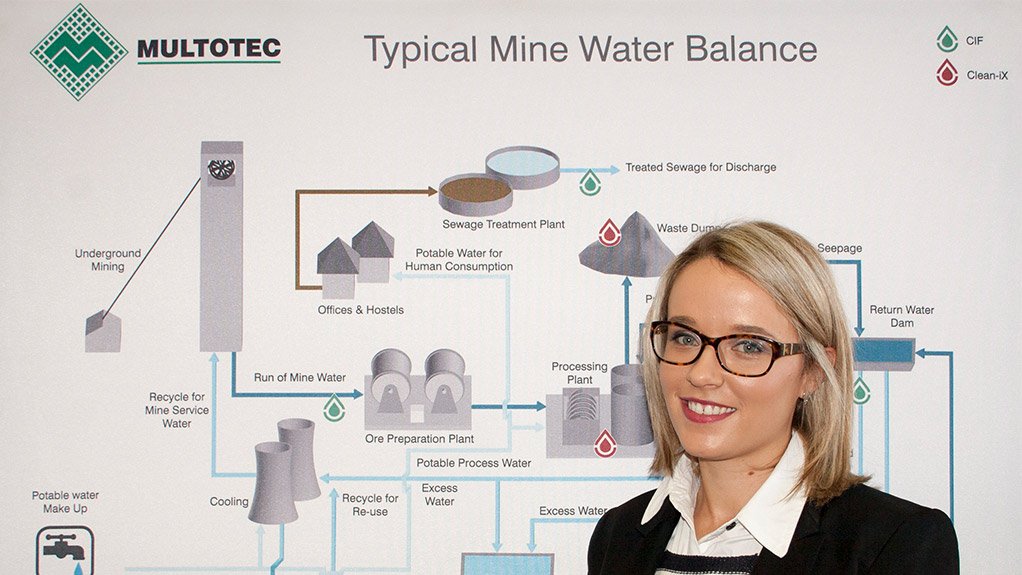

CARIEN SPAGNUOLO During the testwork, we were able to simulate the effect of changing feed conditions on the DeSALx system – proving its ability to adjust effectively to these variable conditions

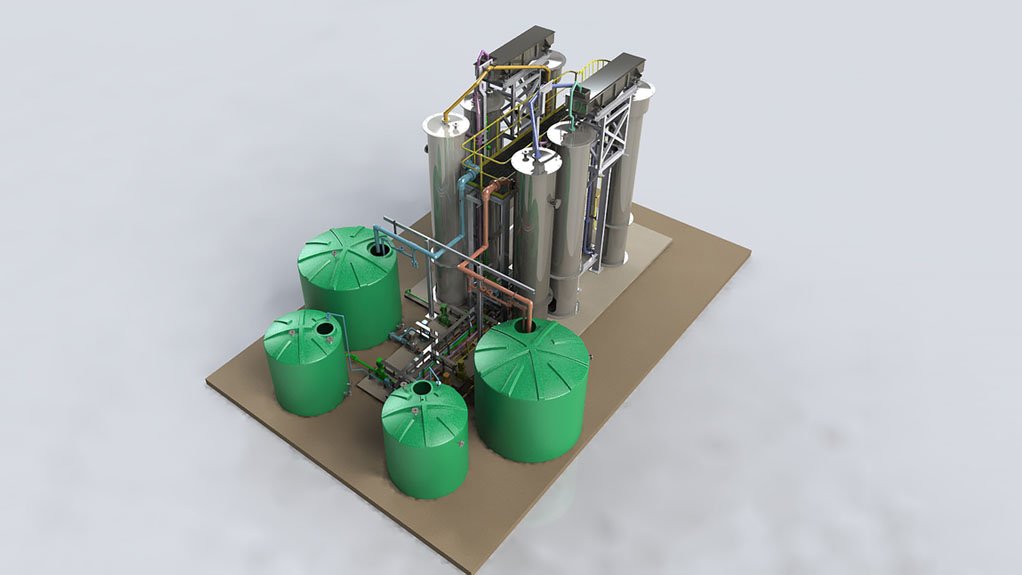

OMAN PLANT The dual stage continuous ion exchange technology implemented for Multotec’s project in Oman, enabling the water treatment plant to operate at high water recovery

After extensive testwork and design, international mineral processing specialist – with a local subsidiary based in Kempton Park – Multotec Group is commissioning a full-scale DeSALx plant to treat wastewater from a flue gas desulphurisation scrubber, at a mineral processing plant in Oman, in the Middle East.

According to Multotec Process Equipment senior process engineer Carien Spagnuolo, the DeSALx technology being used is also being combined with more traditional technologies to achieve water recoveries exceeding 90%.

“The pyrometallurgical antimony plant, in which we are installing at this facility, is located in a very water-constrained area, requiring a high level of water recovery and permitting no liquid effluent from the site,” says Spagnuolo. “The antimony roaster produces wastewater with high levels of heavy metals, including antimony and arsenic, which need to be precipitated in a pretreatment phase.”

Based on the Continuous Ionic Filtration (CIF) process from Multotec’s Australian technology partner CleanTeq Water, DeSALx uses two stages of CIF to desalinate brackish water and enables this effluent treatment process to operate at a much higher water recovery than conventionally possible.

“This is achieved when the system is used in conjunction with an upfront precipitation step,” she says. “This essentially creates a closed loop with no liquid waste production, as the waste from the DeSALx can be routed to the precipitation step.”

The CIF system consists of a series of columns – each designed for a specific function: ion exchange and filtration; resin washing; and resin regeneration. In the DeSALx desalination process, a cationic resin is used in the first stage to remove cations from water, while in the second stage an anionic resin is used to remove anions.

DeSALx Plant in Oman

“Water produced using this technology has low total dissolved solids (TDS) and a neutral pH,” says Spagnuolo. “The system is regenerated with sulphuric acid and lime – both low-cost chemicals – producing a brine slurry saturated with gypsum.”

The Oman plant comprises two precipitation steps. The first is dedicated to precipitating antimony, arsenic and heavy metals using ferric chloride to remove them from the limestone scrubber blowdown, while in the second step a lime precipitation neutralises the acid quench blowdown and treats the brine or waste produced by the DeSALx system.

“Once the streams have been pretreated in this way, they are fed into the dual-stage continuous ion exchange system to remove the high concentrations of calcium and sulphates,” she says. “This enables the reverse osmosis system to operate at these high water recovery levels.”

The water treatment plant, which produces ten cubic metres an hour of potable quality water for reuse within the antimony recovery plant, also includes a Multotec filter press to dewater solid waste.

To achieve the optimal design, Multotec conducted a lengthy testwork programme at its dedicated laboratory in Spartan near Johannesburg. This included simulating the precipitation, continuous ion exchange and filtration unit processes on both a bench-top and laboratory pilot scale.

“These tests gave us the basis for our design, while confirming that the proposed process would remove the necessary elements down to the required levels,” she says. “During the testwork, we were able to simulate the effect of changing feed conditions on the DeSALx system – proving its ability to adjust effectively to these variable conditions.”

The project installation has been completed and commissioning is in progress, with final commissioning expected to be finalised in the final quarter of 2018.