Maximising grinding efficiency and reducing wear with KREBS® SmartCyclone™

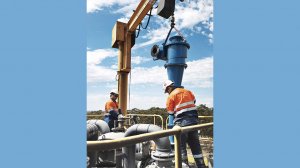

Installation of a KREBS® gMAX15 cyclone

The KREBS® cyclone brings significant advantages to mill circuits the world over

Efficient operation and minimal downtime are crucial for maintaining productivity and profitability in grinding circuits. To address these challenges, many operations are opting for the KREBS® SmartCyclone™ technology from FLSmidth.

According to Abrie Schutte, Senior Applications Engineer at FLSmidth responsible for the KREBS® pumps cyclones and valves product business line, this innovative technology combines advanced monitoring and automation features to optimise closed-circuit grinding operations.

“SmartCyclone™ integrates various components and software to provide a comprehensive solution for grinding circuit management, and significantly incorporates roping sensor technology, wear detection technology, a wireless controller system and ECS/ProcessExpert® process control software,” Schutte says. “End-users have found that by leveraging these elements, maintenance planning is enhanced, wear reduced and there is an overall improvement in grinding circuit performance.”

The wear detection technology of SmartCyclone™ employs specialised sensors to monitor the wear status of cyclone components. This real-time information enables operators to proactively plan for part replacements and schedule maintenance activities, minimising unexpected downtime caused by component failures.

Schutte further explains that an automated monitoring system is a key feature of SmartCyclone™. “This is important as it allows operators to detect wear and troubleshoot issues from a centralised control room, eliminating the need for manual equipment inspections with a reduction in associated risks.”

By promptly identifying and addressing potential problems, process disruptions are minimised, ensuring optimal performance of the grinding circuit.

The SmartCyclone™ system also includes a roping detection feature, which identifies and corrects disturbances known as "roping." Overloaded cyclones or those experiencing roping can lead to increased bypass of coarse solids to the overflow and greater particle size variation.

“This accumulation of slurry can adversely affect downstream equipment, such as flotation cells. By monitoring and detecting roping, operators can confidently operate the plant closer to its limits, thereby increasing production capacity and improving mineral recovery,” he says.

By integrating SmartCyclone™ with ECS/ProcessExpert software, the grinding circuit's performance can be further optimised. The system dynamically adjusts variables such as water addition, pump speed and the number of operating cyclones based on real-time data from SmartCyclone™ sensors. This continuous optimisation enhances particle size distribution, maximises mineral recovery and improves the overall efficiency of the grinding circuit.

SmartCyclone™ offers a comprehensive solution for closed-circuit grinding operations. By leveraging advanced sensor technologies, automated monitoring and process control software, this innovative system empowers operators to enhance maintenance planning, reduce wear, and optimise the performance of their grinding circuits.

“With its ability to detect early warning signs, troubleshoot potential issues and dynamically adjust variables, SmartCyclone™ sets a new standard for smart and efficient grinding circuit management,” Schutte concludes.