Mines Convert To Warman® Froth Pumps

Blurb for online publications

Two mines in South Africa’s Limpopo province proved the value of Weir Minerals’ Warman® AHF pump range in pumping frothy, high density and viscous slurries.

Mines Convert To Warman® Froth Pumps

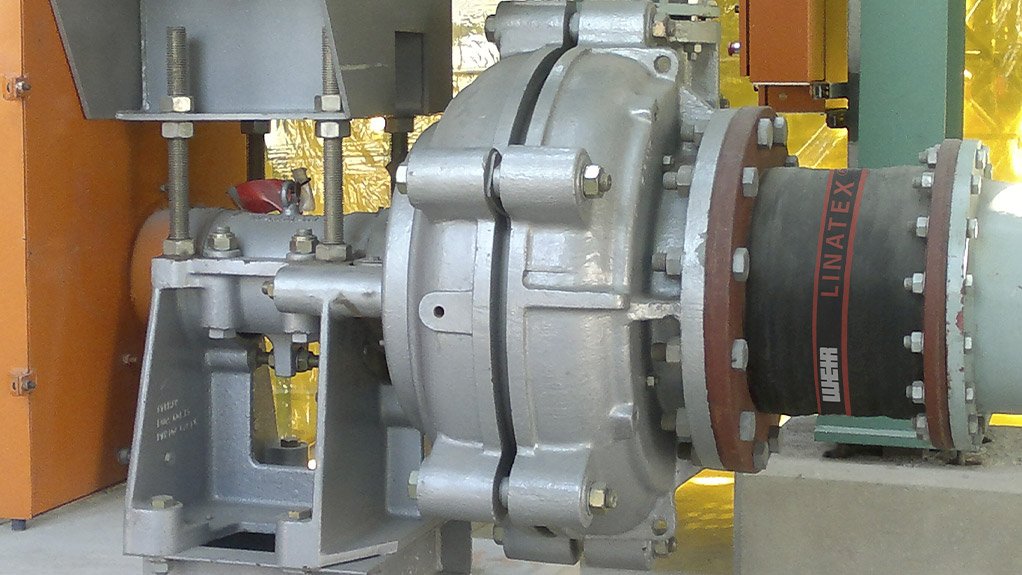

The value of Weir Minerals’ Warman® AHF pump range in pumping frothy, high density and viscous slurries has been successfully proven at two mines in South Africa’s Limpopo province – one in platinum and the other in phosphates. –.

Handling froth in some process circuits can be very challenging, as froth will air-bind a conventional slurry pump. In froth applications, the Warman® AHF inducer impeller solves this problem, producing far less surging. The inducer impeller and oversized inlet enhance the movement of the froth, high density or viscous slurries into the impeller, facilitating effective transportation. In addition, its higher efficiencies mean a smaller pump will deliver the required results.

At the platinum operation, a Warman® AHF 2 pump was commissioned in early 2016. It has met the specified flow rate of 40 m3/h with no pump-related stoppages, repairs or replacements. A 12 month trial period showed that the unit saved the mine over R200,000 when compared to the cost of the competitor pump installed previously. Based on this, the mine replaced another eight competitor products with Warman® AHF pumps. It has approved the Warman® AHF 3 pumps as standard for all frothy applications at the plant’s first flotation section, and Warman® AHF 2 pumps for the second flotation section.

The Warman® AHF pumps – with Hi Seal® expeller (dry gland) design – were also tested in a viscous slurry application at the phosphate mine for six months. They demonstrated that they could continuously pump the high density viscous underflow slurry at relative densities above 1,90. As a result, the customer purchased the pump and began upgrading all the remaining concentrate thickener underflow pumps to the Warman® AHF pump technology.

This reduced the plant’s operational costs significantly, reduced dewatering and concentrate moisture extraction operations, improved filtration efficiency and increased concentrate throughput to the dryers. The Warman® AHF pump also extended the underflow pumping boundaries and the overall reliability of the thickener underflow pumping system.

Other field and laboratory tests have proven that the Warman® AHF pump has largely overcome the problem of high density viscous underflow slurries, with negligible effects on head at slurry yield stresses up to 200 Pa.

“The approach to solving any thickener underflow pumping problem must be based on a thorough understanding of the entire application, the mineralogy and rheological behaviour of the slurry,” says Jacques Pretorius, Weir Minerals Africa’s pump product development specialist.

“Successful thickener underflow pumping projects are only achievable through involving a team of thickener engineers, pumping engineers and rheological consultants. Weir Minerals’ pump trial campaigns confirm the successful operability of the Warman AHF pumps in viscous slurry applications,” he concludes.