Partnerships will define the future of proximity detection in African mining

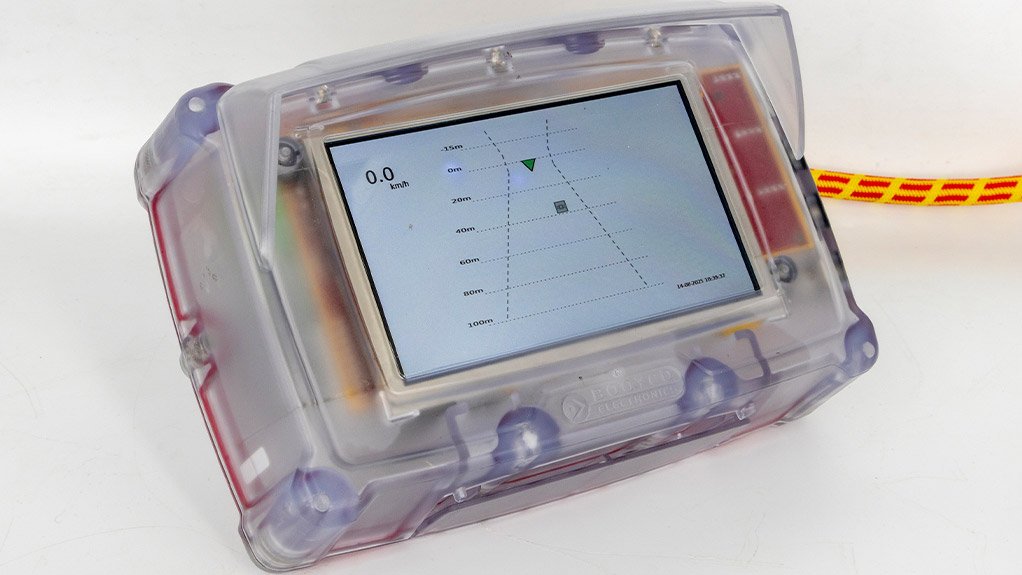

Booyco Electronics continues to advance proximity detection systems (PDS) technology, transforming it from a simple collision avoidance tool into a smart data-driven safety solution.

Anton Lourens, CEO of Booyco Electronics.

By integrating RFID, cameras and GPS, Booyco Electronics’ PDS technology now provides valuable behavioural insights that enhance operator safety and efficiency.

Data collected from Booyco Electronics’ PDS sensors helps mines identify risky driving habits such as harsh braking or cornering, enabling targeted interventions and training.

A proactive approach to safety relies on using PDS-generated data to identify high risk zones and improve segregation between people and machinery.

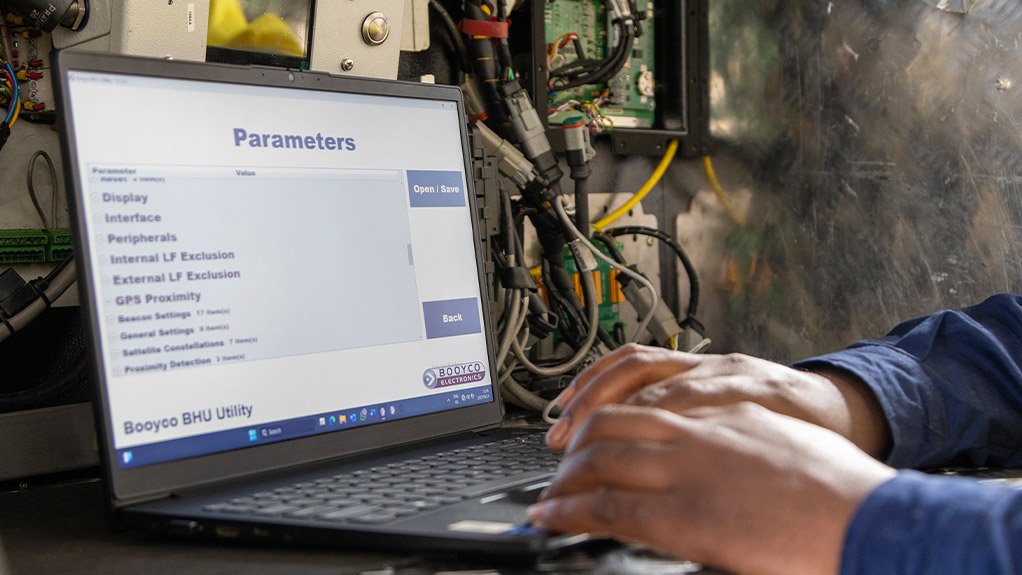

Booyco Electronics’ BEAMS software suite allows mines to interpret PDS data effectively, turning information into actionable safety and productivity insights.

With partnerships at the heart of this year’s Mining Indaba Africa theme, Booyco Electronics highlights why sustained industry-wide collaboration remains essential to advancing proximity detection systems (PDS) across the continent.

“While meaningful progress has been made, true success depends on all stakeholders being aligned - from PDS suppliers and original equipment manufacturers (OEMs) to the mines themselves and regulatory bodies such as the Department Mineral and Petroleum Resources (DMPR),”Booyco Electronics CEO Anton Lourens says. “Our engagement must continue and strengthen, to shape the responsible and effective rollout and adoption of PDS.”

Drawing on more than 19 years of pioneering experience since it introduced what was then known as collision warning systems, Booyco Electronics has walked the road alongside mining operations and OEM partners, says Lourens.

“We are proud to have helped develop and evolve the technology, while navigating the regulatory shifts and ensuring practical integration on the ground,” he says. “One of the most critical pillars of successful PDS implementation remains change management - and we are seeing more customers adopt a structured phased approach.”

He applauds this trend, emphasising how it ensures buy-in at every level - from operators to management - creating safer more responsive mining environments.

“In an era where safety performance, compliance and technology convergence are accelerating, partnerships are no longer optional,” he explains. “They are the foundation that enables Africa’s mines to adopt effective future-ready PDS solutions; our long-standing industry relationships remain central to driving this shared journey.”

With South Africa’s legally mandated Level 9 vehicle intervention, which requires TMMs to automatically slow or stop to prevent collisions, the country has seen accelerated collaboration across the sector. However, implementation remains uneven with mines needing more than hardware and technology to achieve sustainable adoption. Resistance from operators, concerns about production delays and fears of nuisance trip-outs can derail implementation, notes Lourens.

“This is where structured partnership adds strategic value,” he says. “Mines that involve production, finance, human resources and health and safety departments at the planning stages see higher acceptance and lower disruption during implementation.”

Risk-led planning is another shared responsibility requiring joint effort. A PDS deployment only succeeds if the mine’s baseline risk assessment is current, site-specific that have been aligned with their traffic management plan.

“Without this foundation, there is no reliable basis for deciding where PDS should intervene, which vehicles present the greatest danger or where operational flow needs redesigning,” Lourens continues. “Baseline assessment is not simply a legislative requirement; it guides meaningful collaboration between mines, engineers and technology suppliers in determining how PDS will work underground and on surface.”

Proper operational readiness is another area where strong partnerships are vital for successful outcomes. Even mines that have purchased PDS hardware sometimes lack alignment between site’s engineering and production teams, leading to system bypassing, delayed commissioning or poor operator acceptance.

“This is why Booyco Electronics now assists with operational readiness assessments,” he says. “This is to go beyond confirming that the technology fits the application. This approach helps to ensure that people, processes and infrastructure are aligned before deployment begins.”

He notes that, on an international level, detection technologies are evolving toward sensor fusion – another major partnership frontier.

“Mines increasingly operate mixed fleets from multiple OEMs, each with different control logic,” Lourens explains. “Efforts to standardise interface requirements are helping build common ground, but supplier-to-supplier cooperation remains essential to achieving full fleet-wide protection.”

He reiterates that partnerships are increasingly recognised as an operational requirement for ensuring that PDS contributes effectively to mining’s goal of zero harm.

“PDS now sits at the intersection of regulatory enforcement, mine planning, OEM equipment design and mine-site behavioural change,” he concludes. “No single stakeholder can deliver all these elements in isolation, which is why Booyco Electronics continues to work alongside mines, machine manufacturers and regulators to ensure both compliance and real-world effectiveness.”

On behalf of Booyco Electronics

www.booyco-electronics.com

Facebook: https://www.facebook.com/mybooyco/

LinkedIn: https://www.linkedin.com/company/booyco-electronics/

X: https://twitter.com/mybooyco

Instagram: https://www.instagram.com/mybooyco/

From Coralynne & Associates

communicate@coralynne.co.za

X : @Coralynne_Assoc

LinkedIn : Coral-Lynn Fraser-Campbell