Spiral beneficiation boost for coal industry

CHRISTINA RAMOTSABI A recent order will see Multotec delivering six SX10 spirals to Indonesia for a facility that specialises in coking coal applications

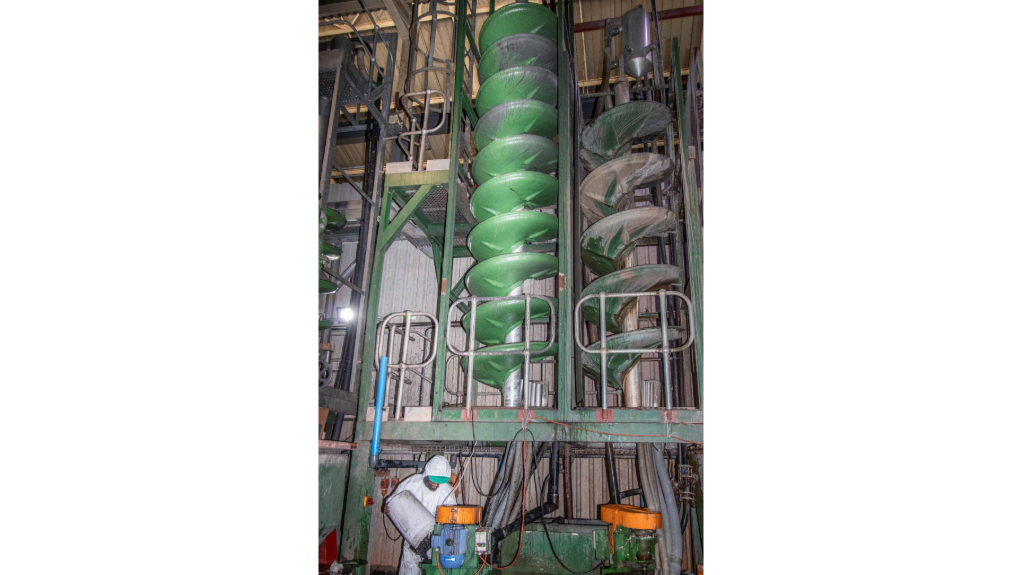

SWIFT SPIRAL SEPARATION MultoteC spiral separators are proudly manufactured in South Africa and delivered to local and international customers.

SX10 SPIRAL SEPARATOR SX10 SPIRAL SEPARATOR The Multotec SX10 spiral that provides a lower cut point of between 1.5 – 1.55 g/cm³’s testwork was conducted at its facilities in Spartan

Mineral processing original equipment manufacturer Multotec is making headway in putting its SX10 spiral separator – which has been subjected to development processes over the past five years – to efficient use in local and international coal mining industries to prove its “value-add” bona fides, says Multotec process and applications engineering GM Christina Ramotsabi.

The company’s recent projects include test work that has been conducted in South Africa, whereby Multotec sourced coal materials from various South African customers’ collieries to showcase the SX10 spiral separator’s ability to produce low-cut density coal product, which, in turn, leads to the production of a higher-quality coal for miners and processors.

The locally sourced materials were taken to Multotec’s Spartan-based facility, in Johannesburg, for testwork and results were shared with customers in South Africa.

Further, when conducting test work in the US, Multotec had to ship several SX10 spiral separators to a US-based partner facility.

The SX10 also boasts flexible and robust qualities, such as being able to separate out gangue materials from coal ore, which will prove efficient in creating a high-grade coal quality.

This new three-stage-in-one spiral technology allows for the coal to undergo separation thrice, instead of twice when using a conventional spiral, such as the SX7 and MX7.

“Traditional spirals usually provided a cut point between 1.6 g/cm3 and 1.8 g/cm3, but the SX10 provides an even lower cut point, between 1.5 g/cm3 and 1.55 g/cm3,” says Ramotsabi.

Unlike other spirals that produce low-cut coal, but that compromise on feed-rate and throughput, the SX10 maintains both an enhanced feed-rate and throughput. This is what sets the SX10 apart from competing traditional and other low-cut spirals.

When conducting testwork, using customer sourced coal material, the SX7, MX7 and SX10 are used in comparative testwork to separate gangue materials from batches. Thereafter, results from every spiral type are compared and, in each case, the SX10 has proven to be the top-performing spiral, she added.

SX10 spiral separators are manufactured in South Africa and can be delivered to local and international customers.

Ramotsabi informs Mining Weekly that a recent order will see Multotec delivering six SX10 spirals to Indonesia for a facility that specialises in coking coal applications – “one of the many early accomplishments” for Multotec’s SX10 range.

“The success of the SX10 separator is important to us because it demonstrates our ability to be innovative and to listen and take note of what customers require, before creating a viable solution and bringing it to the market to address their specific problems and needs,” she enthuses.