Spoilt for choice by WEG’s hybrid power, sustainability solutions

Eduardo Werninghaus, CEO at WEG Africa

By including renewable energy sources in its offering, WEG ensures customers can optimise sustainability while not compromising productivity

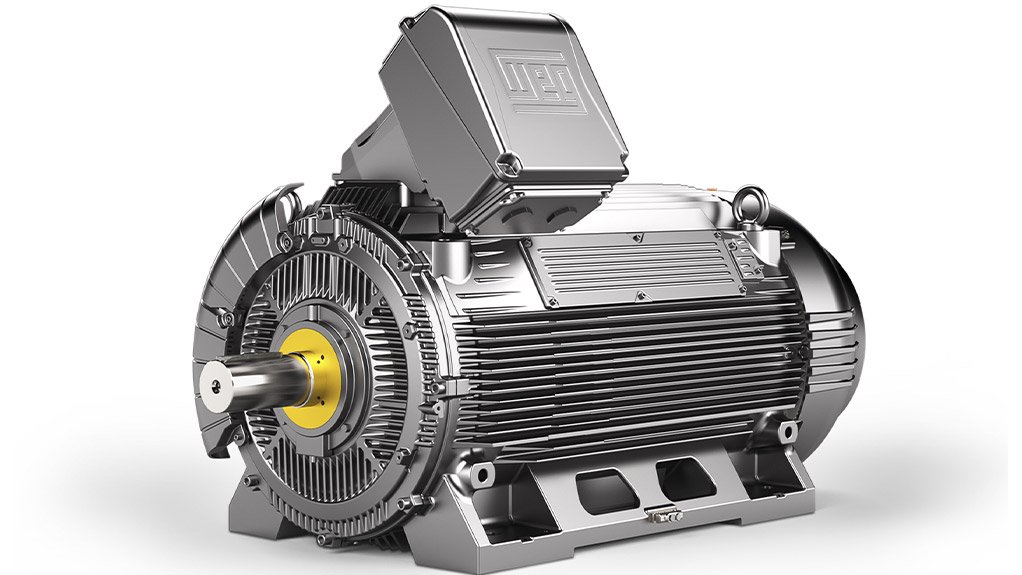

WEG’S extensive range of energy technologies include solar

WEG W23 Sync+ electric motors are the most complete line of high efficiency units, with exceptional efficiency regardless of speed or load variations

WEG has developed its WEGSEE+ platform for calculating potential energy savings

Mines today look to partner with original equipment manufacturers (OEMs) who share their commitment to sustainability, and can offer the latest technology to optimise production while reducing their carbon footprint.

This is the view of Eduardo Werninghaus, CEO at WEG Africa, whose exhibit at the Electra Mining Africa highlighted the company’s extensive range of energy technologies – including solar, wind, steam and battery energy storage solution. This diversity of choices, says Werninghaus, allows customers to consider various hybrid energy options to meet their sustainability goals.

“WEG’s important differentiator is that we can draw from our wide selection of energy generation solutions, so we are really unbiased when helping customers find the most suitable design for their specific conditions,” says Werninghaus. “By including renewable energy sources in our offering, we ensure customers can optimise sustainability while not compromising productivity.”

In the field of solar power, WEG has an extensive portfolio of products for all stages of the photovoltaic solar generation projects, with solutions for energy conversion and internal distribution systems. These cover aspects all the way from the plant to the point of connection with the electrical system through high voltage substations.

The focus on clean energy is also driving the expansion of biofuel production, making steam power increasingly relevant to the local economy. WEG has established a leading role in turbogenerator solutions in Brazil, for example, where it has recently supplied systems that this year will add 140 MW of clean energy to that country’s capacity.

“WEG also provides customers with the technology they need to improve energy efficiency – thereby reducing not only their costs but their carbon footprint as well,” he says. “Our WEG W23 Sync+ electric motors are the most complete line of high efficiency units, with exceptional efficiency regardless of speed or load variations.”

These motors can deliver energy savings of up to 30% in comparison to conventional IE3 induction motors using frequency inverters. Werninghaus also points to the cutting edge technology employed in WEG’s frequency inverters, allowing speed variation in three-phase induction motors.

Quantifying the impact of sustainability initiatives is also important, which is why WEG has developed its WEGSEE+ platform for calculating potential energy savings. This allows customers to predict the potential savings achievable by replacing motors, gearboxes and inverters. The tool provides the necessary data for making smart decisions so that resources can be optimised.

Werninghaus highlights how WEG has embraced sustainable production in its own operations, emphasising its understanding of how important this priority is for its customers. As a measure of this commitment, WEG was awarded Gold Medal status from Ecovadis last year. Ecovadis is one of the world’s main global rating agencies for corporate sustainability management.

“We are also judged to be a ‘leader’ company by CDP Climate Change, who focus on assessing companies’ decarbonisation management,” he says. “Our environmental, social and governance (ESG) risk is also classified as ‘low’ by Sustainalytics.”

Part of WEG’s sustainability drive is also to promote local production, which reduces the carbon footprint associated with long haul transportation of products, and promotes the local economy while reducing lead-times for customers. The company’s electric motor production lines in Johannesburg are just one example of WEG’s local resource base. Among its many South African facilities is the Robertsham operation which engineers automation systems, the genset manufacturing operations in Cape Town and now also in Johannesburg, and the transformer manufacturing facilities in Wadeville and Heidelberg.

“Sustainability is at the centre of how we operate as a company, and we were able to reinforce this message at the Electra Mining Africa exhibition,” says Werninghaus. “This drive ensures that we are continuously developing our technology to support our customers’ sustainability goals.”