Stainless steel pump solution for Namibian mine

The Sykes CP150 pump set boasts a maximum flow of up to 172 litres per second, pumping heads of up to 60 metres

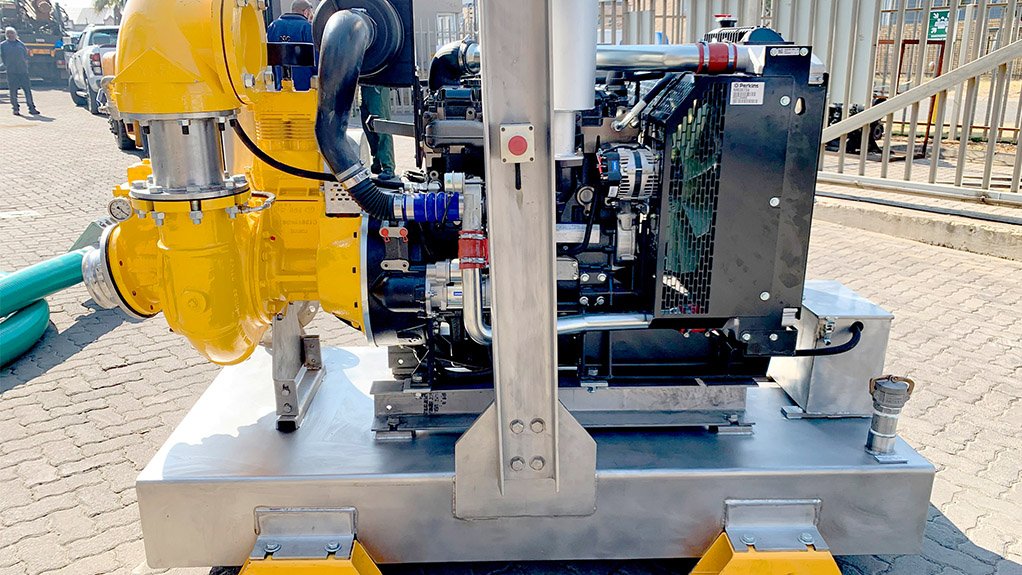

Integrated Pump Rental constructed the entire Sykes CP 150 pump set of grade 316 stainless at its Jet Park facility.

A custom engineered stainless steel Sykes pump set produced by Integrate Pump Rental.

The harsh coastal conditions at a mining operation in Namibia demanded a dewatering solution beyond the ordinary, so it turned to Integrated Pump Rental.

Its remote location, combined with its highly corrosive environment, meant that the mine needed its equipment to be wear-resistant and require minimal maintenance. According to Steve du Toit, rental development manager at Integrated Pump Rental, its solution in this case was enhanced by a customised design.

“Our Sykes diesel driven pumps come standard with stainless steel internal wear-parts, but for this particular application we included a stainless steel volute – for a fully stainless steel pump,” says du Toit. “In addition, we constructed the entire pump set out of grade 316 stainless steel at our facility in Jet Park.”

The company designs and engineers its pump sets in-house according to customers specifications, and in line with mining safety standards. For this project, therefore, stainless steel was also used for the integrated fuel tank, the drop discharge pipework, the single-point lifting frame and the engine mountings.

With its efficient working practices and established supply chain, the pump set was supplied to the customer within five days of the order being received. The work and handover were carried out during South Africa’s hard lockdown in the early days of the Covid-19 pandemic. Integrated Pump Rental was active during this period as an essential service provider to the mining sector.

“Our local manufacture by experienced professionals ensures a cost effective product that is built to the highest standards,” he says. “It also assures customers that our support and maintenance is similarly world class.”

The Sykes CP150 pump set boasts a maximum flow of up to 172 litres per second, pumping heads of up to 60 metres, with a solids handling capability of 77 mm. It is driven by an 83 kW Perkins diesel engine, a popular model in the mining market which is easy to maintain.

“The Sykes pump set can be towed behind a light vehicle, so mines can easily move it in and out of a pit as required,” du Toit says. “Where towing is not possible or permitted, the unit can also be lifted without the need for qualified riggers. Its single-point lifting lug allows the balanced unit to be conveniently lifted with one sling.”

It can also be skid-mounted if it is not frequently moved, or mounted on a road trailer for ease of movement on public roads.