Additives and lubricants deemed successful in sugar processing

ADDICTIVE ADDITIVIES To ensure the local market has access to the latest sugar technology, trends, components and equipment, BMG continually launches new products, that are enhanced by critical technical support

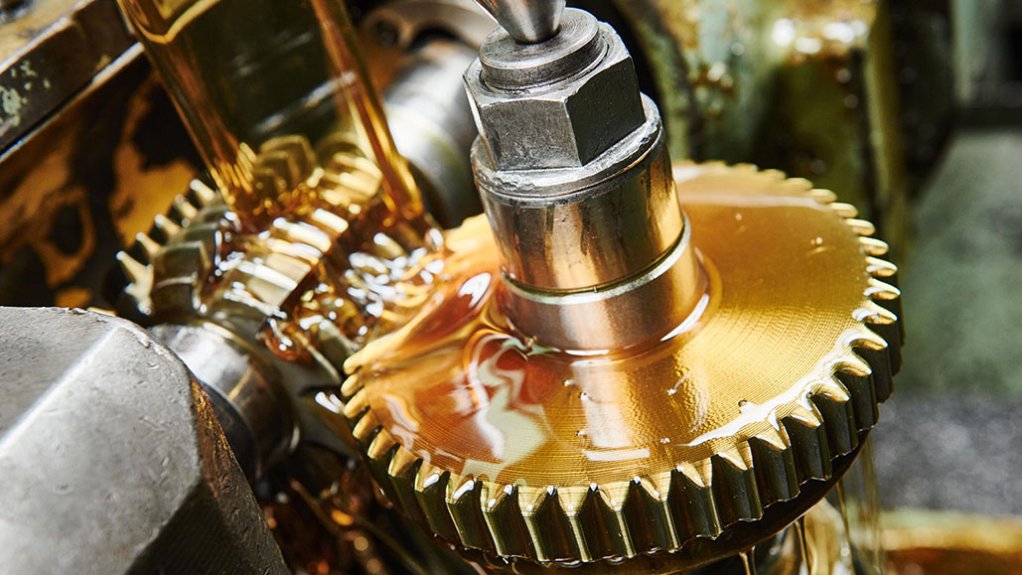

Since the launch of Liqui Moly Cera Tec industrial wear protection last year, engineering solutions provider BMG’s team has received positive feedback from customers in the sugar sector that these additives are proving to be highly effective in protecting gears in sugar mills.

“Problems occur where dust accumulates in the transmission, thus increasing friction between the gears and other components which accelerates wear,” explains BMG agricultural, automotive and lubrication divisions business development manager Carlo Beukes.

“Customers report there are now fewer operational problems, including improved dust control, lower maintenance and replacement requirements and longer service life of critical components.”

Cera Tec Ceramic additives – with exceptional resistance to high temperature and pressure - improve reliability of industrial equipment, lower engine and transmission noise, minimise maintenance requirements and reduce downtime.

Other benefits include energy savings, reduced risk of contamination, lower pollutant emissions and more efficient operating costs, adds Beukes.

Cera Tec – developed by global leaders in additives and motor, transmissions and hydraulic oils Liqui Moly in Germany - is a micro-ceramic solid lubricant suspension based on hexagonal boron nitride (BN) in selected base oils. This product reduces friction and protects the engine and transmission against wear, thus extending service life of assemblies.

The graphite-like structure of resilient ceramic particles, with high mechanical and thermal stability, fill in the roughness in the metal of oil lubricated engines, transmissions, pumps and compressors, thereby preventing direct metal-on-metal contact. An active chemical utilises the existing friction energy to ensure a smooth-running effect that reduces fuel consumption in gasoline and diesel engines.

The < 0.5 µm particle size guarantees optimum filter flow properties and protects against depositing of solid lubricant particles.

“Cera Tec is miscible with all industrial oils.”

He says experts have proven that with the inclusion of Cera Tec additives in transmission oil, the temperature of the transmission oil decreases by up to 20oC. This solution not only offers improved protection of machines, but also reduces the risk of malfunctions and lowers maintenance costs.

In power transmission systems that do not use specially designed additives, it is easy to see how heating destroys lubrication properties and has a negative effect on bearings and equipment. Lower operating temperatures mean longer lasting fuel and components, increasing the transmission’s life expectancy.

BMG specialists advise that when a gearbox is being operated below its full load capacity - with reduced speed or with frequent stop-and-go - the operating temperature of the oil will be lower than it would be under full load. Such applications require gear oils that reliably protect gears and rolling bearings against damage, not only at full-load operating temperatures, but also at lower temperatures.

Oil temperature influences the bulk temperature of gears and bearings, as well as the integral contact temperature, notes Beukes.

“Besides the roughness of the mating surfaces and the applied load, the contact temperature is strongly influenced by circumferential speed.”

At a lower speed, which occurs mostly at the output of a gearbox, the oil temperature, bulk temperature of gears and bearings, and contact temperature, all approximate each other more closely.

A reduction of the oil temperature leads to a substantial increase of oil viscosity during operation, resulting in the formation of a thicker lubricant film on component surfaces, which is critical to protect against damage, he adds.

Moreover, the increase of operating temperature also affects the lifetime of oil. He cites an example saying, if the operating threshold is 80 °C, with every 10 °C increase, the effect is a concerning 50% reduction of the oil lifespan.

“This is very often not a consideration when oil lubrication intervals are set out by maintenance teams.”

BMG’s Liqui Moly Cera Tec additives are also used to enhance the efficiency of vehicles operating in sugar fields and for the transportation of sugar cane to mills and refineries.

“Through BMG’s wide range of energy efficient products - which includes synthetic oils, lubricants and bespoke lubrication systems - and the support of a technically competent team, the company ensures efficient maintenance, extended life of components and energy savings in the sugar sector.”

BMG is a complete process solutions provider to the sugar sector, which means all players in the industry – from cane growers to the sugar refinery - can access all essential quality branded products and essential support services from one reliable supplier.

This integrated approach guarantees lower production costs and higher efficiencies, he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation