DRC project gets apron feeders

FIT FOR PURPOSE TAKRAF South Africa’s apron feeders combine robust, heavy-duty frames with standard chains and rugged pans to provide extremely long service life

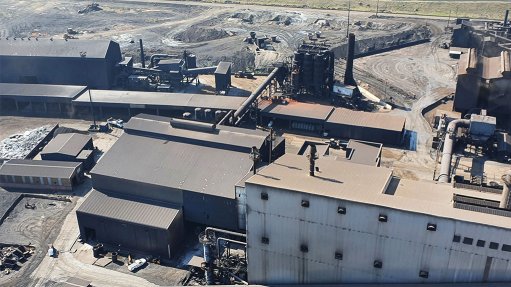

Mining equipment supplier TAKRAF South Africa, part of the global mining solutions provider TAKRAF Group, has supplied two machines for a leading copper/cobalt producer in the Democratic Republic of Congo.

The order was fulfilled in line with Covid-19 restrictions, with installation and commissioning assistance provided remotely, owing to travel restrictions.

The TAKRAF South Africa apron feeders, which are being installed in two new crushing stations at the mine, are 1.83 mm wide, 11.2 m long, with an 18º incline. They feed copper/cobalt ore at 1 200 t/h from a truck tipping point to grizzly feeders, which, in turn, feed jaw crushers. The apron feeders are designed to handle up to 950-mm-diameter lumps, the company explains.

In addition, the demand for the TAKRAF apron feeders from projects across sub-Saharan Africa is increasing, particularly for challenging and abrasive materials handling work, where the apron feeders are preferable to belt feeders, as the latter tend to tear in such applications.

For example, in earlier orders, TAKRAF South Africa supplied three apron feeders to a gold project in the Republic of Guinea, and five apron feeders to an iron-ore project on the West Coast of South Africa.

At 2 184 mm long and 1 830 mm wide, the apron feeders for the iron-ore project were designed as extractable feeders to facilitate maintenance, as they can be individually removed and taken to surface while the others continue operating, the company notes.

It also received orders for a further apron feeder for a major copper mine in South Africa, which already has two installed underground.

TAKRAF South Africa’s apron feeders combine robust, heavy-duty frames with standard chains and rugged pans to provide extremely long service life. The feeders are able to feed and discharge big lump sizes, as well as hard and/or abrasive material.

The apron feeders have minimal maintenance requirements, are installed below dump hoppers and at material storage or transfer facilities, and can be used with the feeder slope inclined up to 22º, it concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation