Atlas Copco Surface Drill Rig used by BMI Drilling on PV Solar Projects

This article has been supplied.

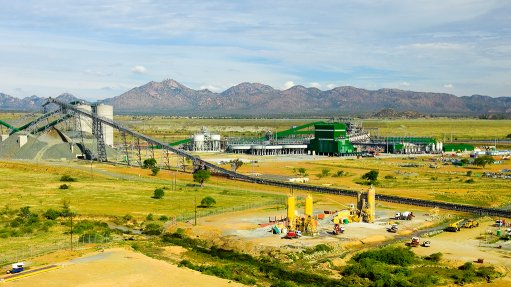

Atlas Copco Mining and Rock Excavation Technique is preferred supplier of surface drill rig equipment to BMI Drilling (previously UKUGRUMBA MINING) for various drilling applications, including drilling of holes for PV Solar Projects in South Africa.BMI Drilling, part of the BMI Group, specialises in blast hole, exploration and borehole drilling as well, load and haul. The company is located in Lesotho, Northern Cape, Free State and Gauteng and has the ability to service the surrounding areas.

“We are proud to be part of the first PV Solar Projects in South Africa and have successfully completed projects across the country as well as in Lesotho,” says BMI Drilling’s Managing Director, David Ireland. “We first ordered a ROC L6 (now a FlexiRoc D50) a DTH (Down-The-Hole Hammer) machine from Atlas Copco for drilling holes for the first PV Solar projects which is in fact still being used on these projects.” Ireland confirms the successfully completion, ahead of schedule, by BMI of the required drilling of holes ranging from 102mm to 300mm on two PV Solar projects. “We hope to receive a contract for another PV Solar project in the Northern Cape where we will use the five FlexiROC D60s that we recently ordered from Atlas Copco.”

According to Ireland, the success of a big contract in Lesotho, where Atlas Copco was preferred supplier, is one of the reasons why BMI Drilling only use Atlas Copco equipment. “We only use Atlas Copco drill rigs fitted with Atlas compressors because the BMI partners’ experience with Atlas Copco over the past five years has proven that the equipment is safe, efficient and delivers good performance.” “In addition, we enjoy using the latest technology for drilling and compressed air from Atlas Copco to show what can be achieved using good technology. Many people have tried to do what they deem to be a simple task using smaller drills from the east, but the Atlas Copco ROC L6 has shown many main contractors that not only is the productivity better, but so are all associated costs and safety,” stresses Ireland.

“Increased productivity delivered by the ROC L6 drill rig is largely due to the DTH hammer (available in 3”, 4”, and 5”),” notes Atlas Copco Mining Area Sales Manager - Surface & Exploration Drilling Division, Kevin Govender. “The hammer capacity is used efficiently thanks to a unique hydraulic cylinder-operated feed system which has a maximum feed rate of 0.9 m/s. The drill is ideal for aggregate and limestone quarrying but is equally at home in mining operations including coal overburden excavation.

The main components of the rig includes a Caterpillar turbo charged diesel engine (up to 440 HP), Atlas Copco two stage screw type high pressure compressor (up to 30 bar), single section boom system and a ROPS and FOPS approved operator’s cabin.

The cost of ownership of the Atlas Copco L6 as well as the company’s service ethics have impressed Ireland. “While the cost of maintenance and ease of maintenance is not easy in the type of equipment that we use, the backup from Atlas Copco assists us in keeping these costs down. This is in line with our company’s mission ‘through successful partnerships and sustainable projects to create wealth and experience for all our stake holders, including skills transfer to our employees’.” Ireland adds that BMI finds Atlas Copco’s after-sales service “to be of a very good standard” and concludes. “With the support of suppliers like Atlas Copco, I believe that BMI Drilling will realise its vision ‘to become the leading drilling company of choice throughout Southern Africa’.”

The BMI Group was established in 2012 when a small drilling operation was needed on a diamond mine in a Southern African country. BMI Compressed Air and BMI Industrial Supplies also form part of the Group which has a client base spanning industries including diamond, coal and iron ore mining, PV Solar Projects and drilling companies.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation