B&E shares mines’ load, risk with broad offering

B&E plant and engineering director Ken Basson talks to Mining Weekly at Mining Indaba. Video & Editing: Creamer Media's Nicholas Boyd.

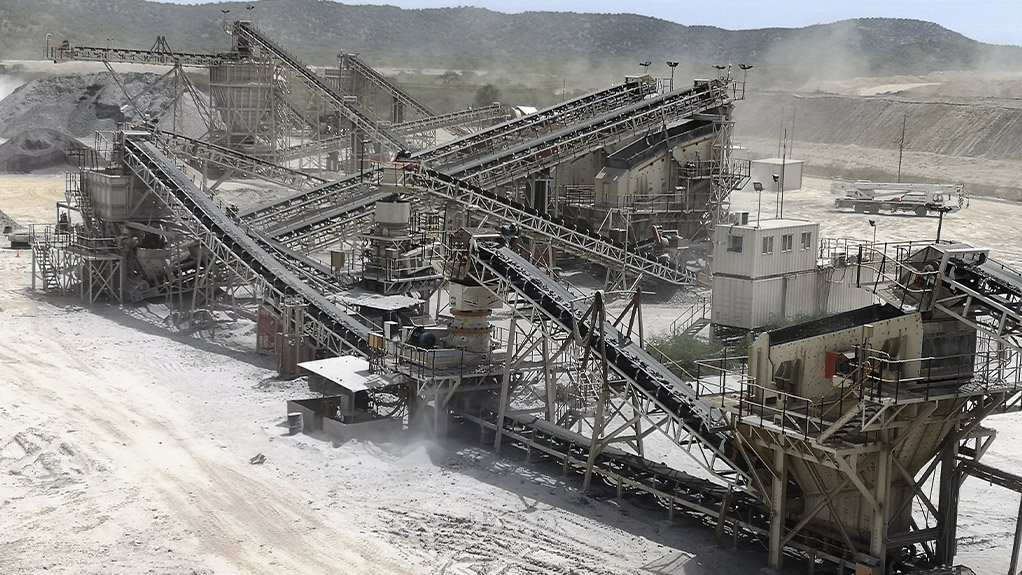

A tertiary crushing plant

A copper crushing circuit

A copper crushing circuit

With buoyant commodity prices attracting considerable investment in mine expansions and new projects, B&E International is growing its support to the sector with a suite of services in mining and processing.

“More than ever, mines are looking to their technical partners for efficiency, reliability, cost effectiveness and reduced risk,” says B&E plant and engineering director Ken Basson, who adds that the company’s growth strategy is built on delivering these benefits, while remaining focused on lowest total cost of ownership.

Basson highlights that the company’s legacy as a designer, manufacturer, owner and operator of process equipment has given it unique insights into developing fit-for-purpose solutions. He adds that this has also given rise to innovative offerings which share risk with customers.

From process guarantees to build-own-operate-transfer (BOOT) options, B&E International helps customers to de-risk their operations from start-up stage onwards.

Basson explains that the BOOT option provides a “partnership model” where project execution and the associated plant performance risk resides with the partner.

“This value offering encompasses all aspects of plant design, manufacture, installation, operation and the financing. With extensive in-house design and manufacturing capabilities, the company offers a fully integrated and risk sharing value offering to its prospective partners.”

He further elaborates that whether the mine owners are from Africa or abroad, the company’s experience in running its own plants allows it to take responsibility for a range of on-mine functions.

“Where new projects may still be building up their capability and resources, we can even conduct blasting, loading and hauling through to processing,” he comments.

With experience across commodities including coal, copper, diamonds, gold, iron-ore, manganese and aggregates, B&E International targets customers from large to junior miners, as well as project houses.

Cognisant of the growing focus in Africa on local procurement and supplier development, Basson says the company can add value by empowering new entrants.

“Large miners can look to us to partner with emerging local players, supporting them in the acquisition and application of equipment,” he says, adding that this makes “a vital contribution to local empowerment, building up new businesses and transferring vital skills – while our experience assures the mine of performance delivery”.

For junior miners, the company can assume a level of both financial and operational risk.

Basson says the BOOT model relieves the new operator of considerable capital demands, while B&E International ensures that the plant operates to specification and delivers the product required.

The company has shown the benefits of this approach in Namibia, for example, where it contracted with an open-pit, heap-leach copper operation. The contract involved primary, secondary and tertiary crushing, agglomeration and plant maintenance, as well as operation of the heap leach stacking process.

“Importantly, our experience in operating our own plants also dictates our design philosophy , so they are easy to operate and maintain in the context where they are used,” he says.

“We prioritise both the equipment’s duty and its reliability – for optimal uptime.”

With a fully-fledged and integrated design and manufacturing facility, B&E International leverages a skills base of engineering skills that includes mechanical, electrical, process, civil and project management expertise. Its technical support teams ensure that customers’ equipment in the field is well serviced to avoid unplanned downtime.

The company’s expertise in mineral processing also underpins its consulting role, where it conducts plant optimisation studies to trouble shoot and to improve the performance of clients’ mining operations .

Basson emphasises that the company operates across South Africa and northwards with experience in countries like Botswana, Mozambique, Tanzania and Uganda. There are also opportunities being explored through its sister companies in Western Australia.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation