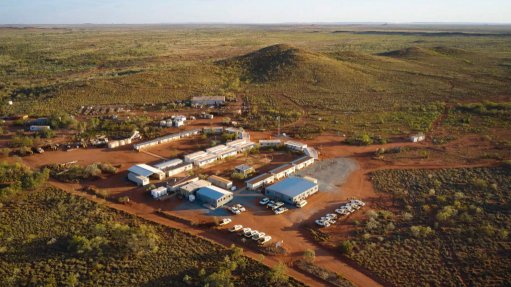

Carajás S11D iron-ore project, Brazil

Name of the Project

Carajás S11D (S11D) iron-ore project.

Location

Pará, Brazil.

Client

Vale.

Project Description

S11D is named after its location – orebody S11, Block D. The mining potential of orebody S11 is ten-billion tons of iron-ore and that of Block D 2.78-billion tons of iron-ore.

It is the largest project in the history of Vale and the iron-ore industry.

The project has a nominal capacity of 90-million tonnes a year of iron-ore, with proven and probable reserves of 4.24-billion tonnes, an average ferrous content of 66.7%, low impurities and an estimated cash cost (mine, plant, railway and port after royalties) of $15.00/t.

S11D will increase Vale’s logistics capacity to 230-million tonnes a year and involves the construction of a rail spur, new railway sections with dual tracks, rail terminals and onshore and offshore investments.

In line with Vale’s long-term objective of sustainable value creation, it has developed technological solutions focused on environmental protection, with more efficient use of natural resources and the reduction of pollutants emission.

The truckless mining concept will result in replacing the off-road trucks with excavators and mobile crushers, which will extract the iron-ore and feed the conveyor belts that will transport it to the beneficiation plant.

Implementing the processing of iron-ore using its natural moisture (dry process) will further mitigate the environmental impacts. This technique eliminates the generation of tailings using the maximum amount of ore, since the finest feeds, which would be lost in the conventional process, are in the final product.

Once the S11D mine and plant are operating, water consumption will decrease by 93% and fuel consumption by 77%, allowing for a 50% reduction in greenhouse-gas emissions, compared with using conventional methods. The dry process will also reduce electricity consumption and eliminate the need for a tailings dam, minimising the interference in native environments.

Jobs to be Created

Not stated.

Net Present Value/Internal Rate of Return

Not stated.

Value

$14.4-billion.

Duration

S11D is expected to start up in the second half of 2016 and deliver full capacity production in 2018.

The start ups for CLN S11D will occur from the first half of 2015 to the second half of 2018.

The project is expected to reach full production by 2018, enough to fill 225 Valemax ships – the largest cargo carriers in the world.

Latest Developments

Vale has received a ten-year operating licence for its Carajás S11D project.

Brazil’s federal environment agency Ibama has said in a statement that Vale has fulfilled 16 specific conditions to operate the 90-million-tonne-a-year operation.

The S11D mine and plant is 96% physically complete as at October 30, with hot commissioning progressing well. The $14.4-billion S11D project’s start-up is slated for the end of 2016, with the first commercial shipment to take place in January 2017.

The operating licence for the S11D mine and plant is an important milestone to consolidate Vale’s position as the largest and lowest C1 cash cost producer in the world.

Key Contracts and Suppliers

None stated.

On Budget and on Time?

Yes.

Contact Details for Project Information

Vale, Roberto Castello Branco, tel +55 21 3814 4540 or email Roberto.castello.branco@vale.com.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation