Clean coal technologies across the coal value chain

Clean coal technologies overview in the power plant – electricity generation and suitability to South Africa

Benchmarking – a practice commonly used in industry – is the process of comparing the performance of one plant to that of another reference plant, to have sight of “best practice” with the goal of driving a continuous improvement mindset.

The world is moving towards a target of halving greenhouse gas emissions by the year 2030, which includes reducing SOx, NOx, CO2, and particulate matter (PM) emitted by coal-fired power plants.

South Africa has an abundance of coal. Surely, this should ignite a drive for investment and innovation, especially in the technical selection of unit operations (e.g. boilers) aligned with achieving the highest efficiency ratings and lowest emission targets? The disconnect in this ecosystem has led to South Africa being confined to subcritical technology and labelled as a country that should decommission its coal-fired power plants, a poor reflection of the culture of clean coal technologies (CCTs) in the energy sector.

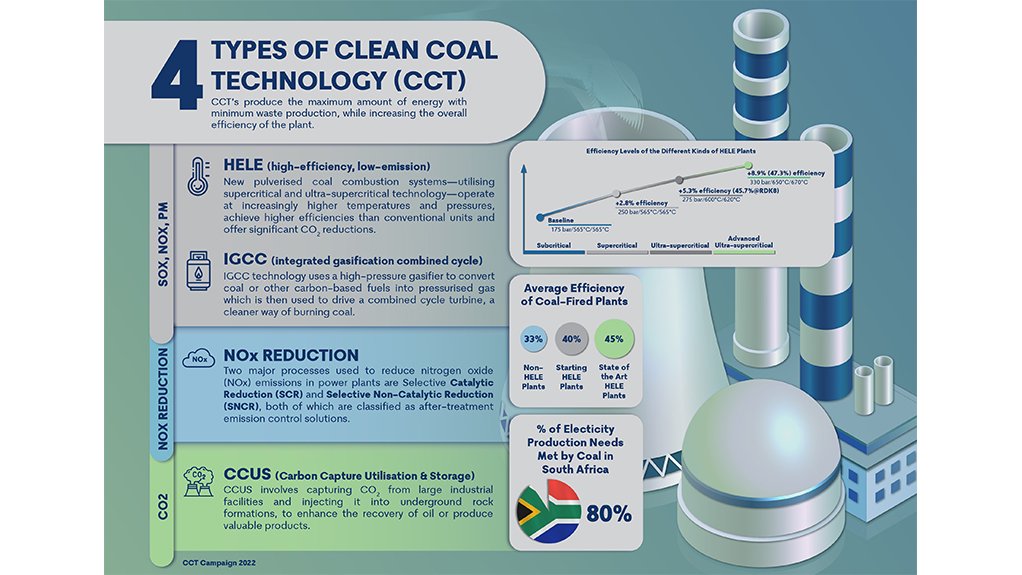

To ensure a sustainable energy future and greater energy resilience, the country's strategic priority should be CCTs. The 1 500 MW coal-fired power plant outlined in the 2019 Integrated Resource Plan should be built from these technologies. CCTs, in power generation applications, are technologies that produce the maximum amount of energy with minimum waste production, while increasing the overall efficiency of the plant. The three main CCTs deployed and operational globally are High-Efficiency, Low-Emission, or HELE, pollution abatement, and carbon capture utilization and storage (CCUS) technologies.

With calls for more stringent global emission standards, many countries are deploying technologies to reduce pollution from their coal-fired power plants.

The Maasvlakte Power Plant 3 in Rotterdam is known as a flagship European Union (EU) power plant. This is an ultra-super-

critical (USC) unit of 1 100 MW with an efficiency of 47% (net, LHV), commissioned in 2016 and can cofire up to 30% of biomass. It is carbon capture-ready plant, with an average emission level of SO2 (5–25 mg/m3), NOx (60–65 mg/m3) and PM (1–2 mg/m³) (IEA Clean Coal Centre, 2016).

Another option that could be implemented in South Africa is that of the 912 MW coal-fired RDK8 unit in Rheinhafen-Dampfkraftwerk, Germany, with a net thermal efficiency of 47.5% as of 2019 (World Energy, 2019).

All these power plants, in addition to South Korea's Samcheok Green 2 200 Mwe (Sumitomo Heavy Industries, Ltd, 2017) (42.4% net efficiency) and Japan's Isogo (45% net thermal efficiency) (Meti Journal, 2013), meet global required emission standards.

For NOx reduction, primary low-NOx burners or secondary NOx measure can be selective catalytic reduction (SCR) and selective non-catalytic reduction (SNCR). Circulating fluidised bed technology operates at combustion temperatures below 900 ºC, which almost eliminates the production of NOx, with primary reduction or abatement measures achieving NOx levels of less than 150 mg/m3 for large coal units greater than 600 MW. This is more than four times lower than the approved emission standard for new power plants in South Africa. In addition, the application of SCR can achieve NOx concentrations lower than 30 mg/m3.

In the case of SO2 control, flue gas desulphurisation (FGD) can be used, with wet FGD typically removing over 90% of SO2, which complies with the EU emission limits (180 mg/m3). Given that South African coal is low in sulphur, detailed beneficiation could further reduce the sulphur-bearing minerals in our coal, resulting in high quality coal and no need for FGD. A study conducted by the University of the Witwatersrand DSI/NRF SARChI Clean Coal Technology Research group has shown that some of our coals are self-scrubbing, which means limestone or lime slurry might not be required for sulphur removal.

Another CCT that can be applied in the power plant, and other sectors, is the CO2 CCUS. This involves capturing CO2 from large industrial facilities and injecting it into underground rock formations, to enhance the recovery of oil or produce valuable products. The technology was adapted to the 110 MW Boundary Dam plant in Canada in 2014, and the facility is still operational. It has also been demonstrated at pilot plant scale by ENEL in Italy with the aim of preparing for full scale at the 2 600 MW Brindisi Sud.

Some of these technologies, including biomass co-firing, can be adopted to extend the lifespan of the proposed older power plants.

South Africa’s baseload electricity supply is secured through coal-fired power plants. As stated by the World Coal Association, it is not the use of coal but the way coal is used that should be the focus of attention.

Written by Samson Bada, Reyna Singh and Senamile Masango

Please reach out to our CCT campaign with comments, knowledge sharing or sponsorship via SACCTCampaign@gmail.com

The views expressed by the writers herein are based on research, information gathered from the public domain as well as their own opinions. The writers do not accept liability for any loss or damage, errors or omissions in the contents of this article, which may arise during or as a result of transmission.

The writers should be contacted directly for any advice of a technical nature.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation