Company expands footprint in smelting industry

MARIUS BRITZ "WIKA prefers to focus on the resolution of application and industry challenges, therefore creating value for the customer such as improved optimisation, reliability and availability" - Marius Britz

LLOYD TOWNSEND "Adopting the IIoT strategy has enabled WIKA to provide a holistic solution for clients and, with such a solution, one has deep knowledge of the system design, configuration and installation" - Lloyd Townsend

DORCAS POOE "WIKA South Africa has committed its time and expertise to transfer knowledge of technology, technical know-how and a variety of skills to equip the youth “with the tools to make a living”"- Dorcas Pooe

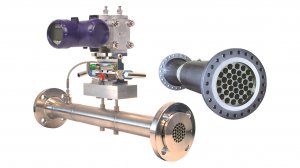

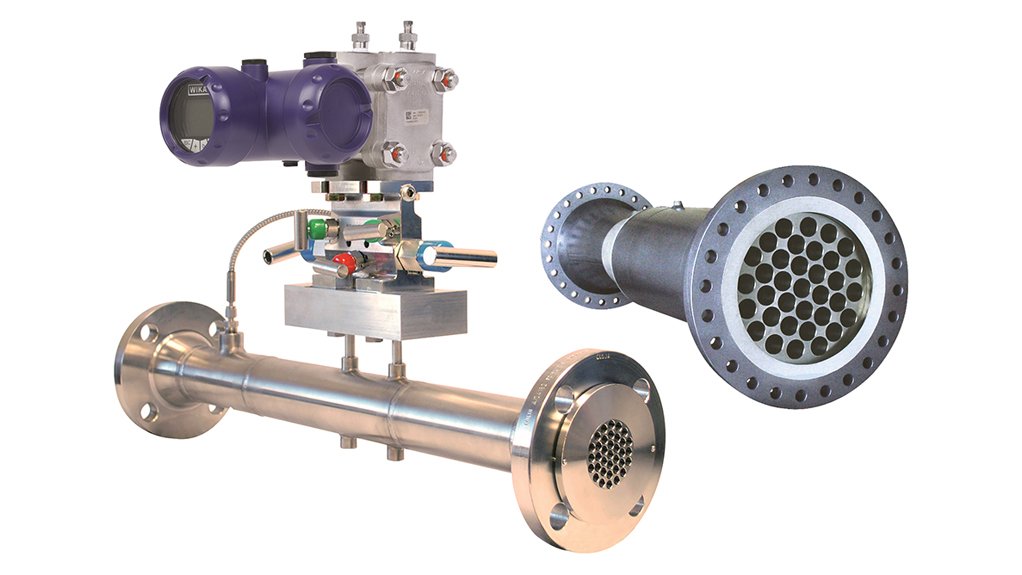

FLOW THE GAS The FlowPak and ProPak flow meters are primary flow elements that can handle the high temperature, and do not require upstream and downstream piping

Pressure, temperature, level, flow and force measuring technology company WIKA South Africa is expanding its footprint in Africa to provide instrumentation solutions for ore smelting operations.

WIKA’s instrumentation solutions are used for measurements under high-pressure conditions of up to 8 000 bar in metal processing, at extreme process temperatures of up to 2 000 °C for metal and glass processing or in applications with highly abrasive process media, notes WIKA Industrial Internet of Things (IIoT) senior consultant Lloyd Townsend.

WIKA’s FlowPak and ProPak flow meters are unique for gas flow measurements in smelting applications (in sinter plants). The gases are at high temperature, which means that many flow measurement technologies are not suitable, says WIKA marketing manager Greg Rusznyak.

The FlowPak and ProPak flow meters are primary flow elements that can handle the high temperature, and do not require upstream and downstream piping.

Moreover, as part of its expansion plan, WIKA has been offered the opportunity to assist a client on the Copperbelt, in Zambia, with a design change for temperature measurement on its furnaces at the smelting plant, adds WIKA export area sales manager Marius Britz.

WIKA consulted with the client prior to providing a solution for the furnace to create a customised instrument; this, says Townsend, is at the forefront of WIKA’s principles, as the understanding of requirements, goals and outcomes form the basis of achieving client satisfaction.

“This way, we can [effect] correct equipment design to ultimately supply a solution that holistically resolves the challenges within each application.”

He says WIKA prefers to focus on the resolution of application and industry challenges, therefore creating value for the customer such as improved optimisation, reliability and availability.

Britz mentions, however, that there are challenges regarding new instruments, applications and processes in the smelting industry.

“There was a challenge with temperature instruments during the commissioning of a section of the client’s plant. With investigation, it was discovered that the process design differed from the actual process parameters. Yet, WIKA, together with the client, was able to find a solution.”

IIoT Strategy

WIKA is a member of nonprofit association LoRa Alliance and a founding member of the IoT connectivity association MIOTY Alliance.

Townsend says adopting the IIoT strategy has enabled WIKA to provide a holistic solution for clients and, with such a solution, one has deep knowledge of the system design, configuration and installation.

“Once the process values have been measured and transmitted, they need to be stored. Thereafter, it is paramount to present the data particular to the requirements of the end-user – an IIoT cloud solution provides the client with a customised application.

This enables WIKA to provide benefits such as process optimisation, automatic alarms, early detection of fault conditions, and diagnostics.

Further, WIKA is collaborating with several global clients on proof-of-concept projects, and is confident that this approach will place the company in a commanding position in the IIoT industry, notes Townsend.

Skills Development Efforts

WIKA human capital transformation manager Dorcas Pooe says WIKA South Africa has developed and implemented sustainable youth employment, learnership and apprenticeship programmes.

These programmes support industrialisation and entrepreneurship, and assist in addressing the challenges of critical and core skills through the Manufacturing, Engineering and Related Services Sector Education and Training Authority, or merSETA, as well as inequality and unemployment among the youth and people living with disabilities.

Pooe states that WIKA South Africa has committed its time and expertise to transfer knowledge of technology, technical know-how and a variety of skills to equip the youth “with the tools to make a living”.

WIKA is committed to achieving positive social impact through the Youth Employment Service (YES) initiative, socioeconomic development activities for schoolgoing children from disadvantaged backgrounds, enterprise and supplier development business linkages and all other sustainable transformation solutions that would empower the previously disadvantaged to meaningfully participate in the mainstream economy.

She says WIKA South Africa’s participation in YES to temporarily employ youth for a fixed-term of 12-months is based on humanitarian and development principles.

The objectives of YES are to offer the youth quality workplace experience and basic wages to become more marketable, thus enabling them to acquire permanent employment.

“The only way to reduce inequality is to give all South Africans, regardless of their economic status, a pathway into work, to build income and invest inclusively.”

Twenty participants are part of the current intake, while another 20 will be enrolled this year. These learners are on career trajectories ranging from office administration to chemical and electrical engineering.

This process is a great benefit to not only the learners but also WIKA, notes Pooe.

“Any learner that takes on permanent employment with WIKA after completing his/her learnership has been mentored in our corporate culture and is already part of the team.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation