Complete crane drive systems available from SEW-EURODRIVE (Pty) Ltd

This article has been supplied.

SEW-EURODRIVE (Pty) Ltd. supplies complete drive systems for cranes, including project planning and design and aftersales service. No matter the operating conditions, these gear units are designed to match customer expectations. Typical applications include industrial, process, ship-to-shore, goliath shipyard and straddle carrier cranes.

Crane drives move heavy weights with low performance levels. In general, only the motion resistance has to be overcome. The industrial gear unit solutions from SEW-EURODRIVE (Pty) Ltd. provide the required torque strength.

Crane trolleys are used in a multitude of different applications and have to meet a wide range of requirements. While port and bridge cranes travel at low speed with a limited operating frequency, overhead traveling cranes and container stacking cranes travel at high speeds with a high frequency.

Another challenge is the alternating direction of rotation (reversing operation), that is the ability to transport loads in both directions. Here the mass moment of inertia is extremely large compared to the mass moment of inertia on the motor side. As a result, gear unit solutions for crane trolleys are primarily responsible for the acceleration and deceleration torque.

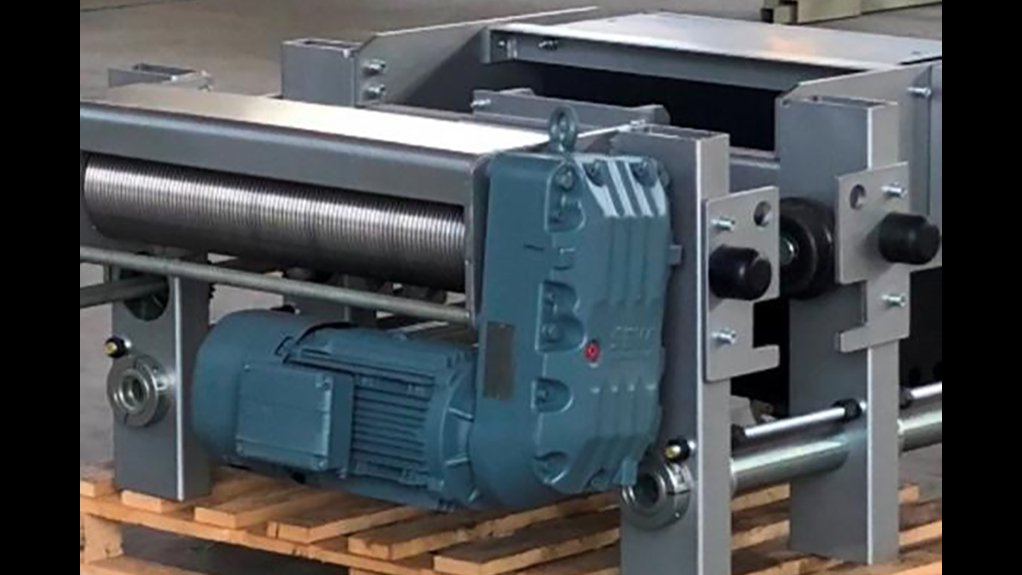

The robust X Series industrial gear units from SEW-EURODRIVE (Pty) Ltd. is an ideal drive solution for these complex operating conditions. A single-source solutions provider, SEW-EURODRIVE (Pty) Ltd. supplies industrial gear units, gear motors, motors, frequency inverters and controllers. This ranges from complete drive packages including couplings, brakes and steel structures to individual components.

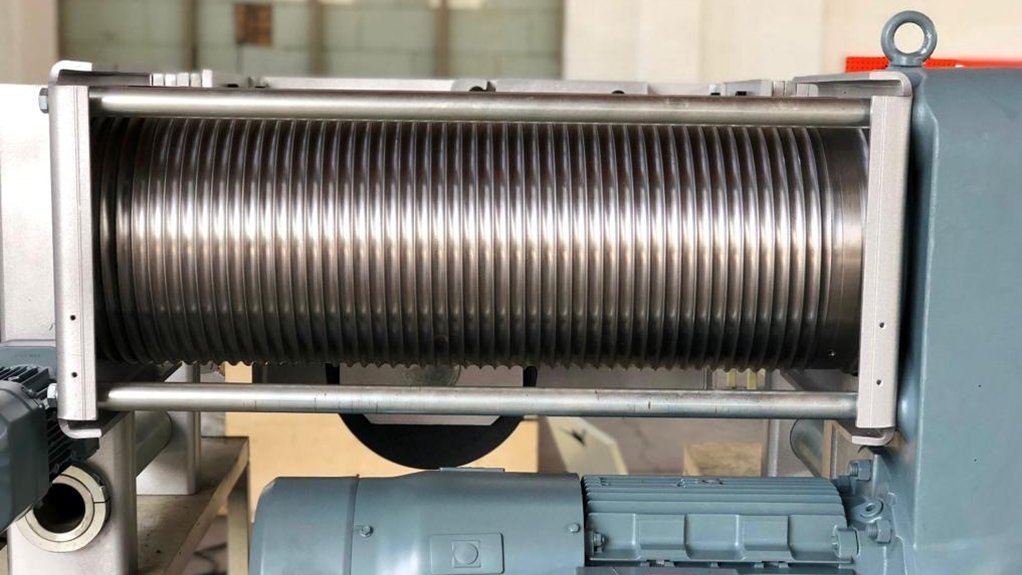

Benefits are a parallel arrangement of the motor and rope drum thanks to a parallel-shaft helical gear unit with a larger centre distance; lower costs and weight, because the helical gear unit with a larger centre distance means it is no longer necessary to oversize the gear units for space reasons; and a lightweight, low-vibration design due to a gray cast iron housing optimised in terms of weight and rigidity.

A perfect fit is guaranteed thanks to finely stepped torque classes from 12.8 to 112 kN and a gear ratio range of 14 to 50. Availability is guaranteed due to the fact that the hoist gear unit is a standardised catalogue product. In addition, a range of options is available to ensure optimum adjustment for the installation required.

The X../HC Series of hoist gear units features a greater centre distance. Hoists often have parallel-shaft gear units in which the rope drum and motor are arranged on the same side of the gear unit. Compact universal gear units often have to be oversized in terms of torque, as the centre distance between the input and output shafts is insufficient.

It is based on the successful X Series, and is available in three or four stages. This means that the options and accessories available with the standard X Series can be combined with specific applications for the X../HC Series..

Connect with SEW-EURODRIVE on Facebook to receive the company’s latest news:

www.facebook.com/SEWEurodriveSA

Media Contact

Nomvelo Buthelezi

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 083 408 8911

Email: nomvelo@ngage.co.za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at http://media.ngage.co.za

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation