Mechanisation drives service offering

![Historical model – Global stress results. [MPa]](https://cisp.cachefly.net/assets/articles/images/resized/0000841716_resized_fig1b1022.jpg)

![Historical model – Detail view stress results. [MPa]](https://cisp.cachefly.net/assets/articles/images/resized/0000841717_resized_fig1c1022.jpg)

![Current model stress results. (Nodal stress averaged) [MPa]](https://cisp.cachefly.net/assets/articles/images/resized/0000841718_resized_fig21022.jpg)

![Current model stress results. (Element stress) [MPa]](https://cisp.cachefly.net/assets/articles/images/resized/0000841719_resized_fig2elm1022.jpg)

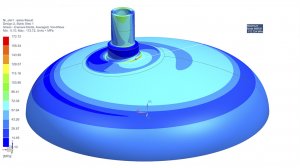

![Current model – Detail view stress results. [MPa]](https://cisp.cachefly.net/assets/articles/images/resized/0000841720_resized_fig2c1022.jpg)

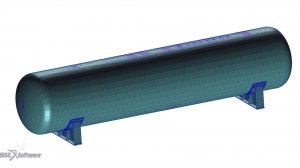

Historical model - mesh layout

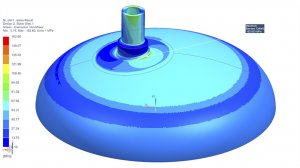

Historical model – Global stress results. [MPa]

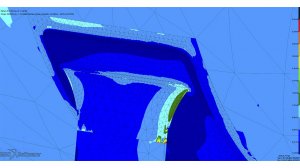

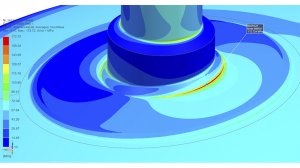

Historical model – Detail view stress results. [MPa]

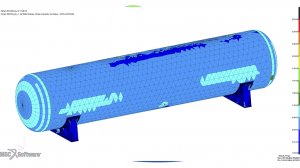

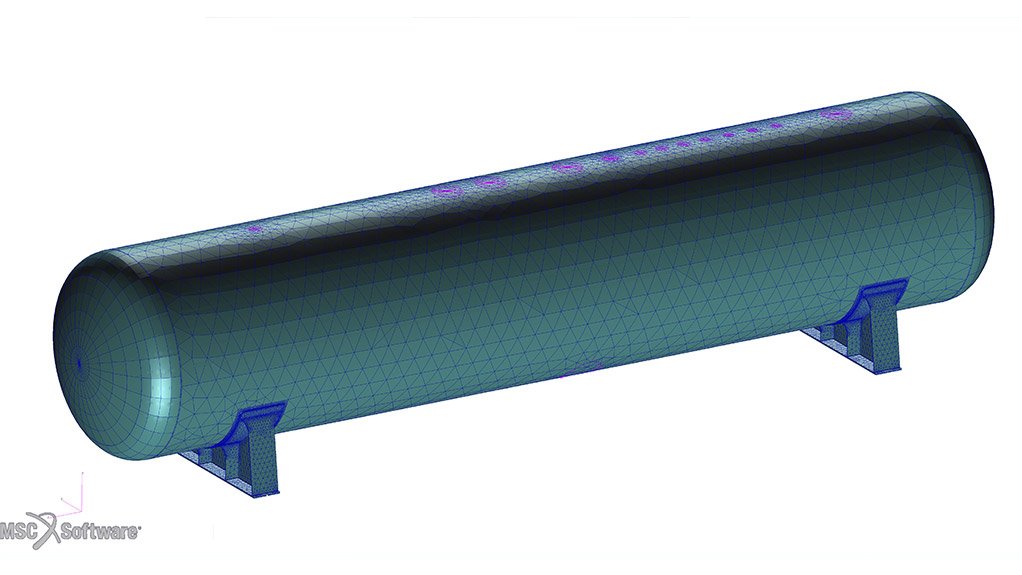

Current model stress results. (Nodal stress averaged) [MPa]

Current model stress results. (Element stress) [MPa]

Current model – Detail view stress results. [MPa]

Structural steel designers and fabricators Structa Group of companies manufactures and supplies a range of infrastructure-related products including water storage tanks and industrial process equipment.

Its subsidiaries, including industrial equipment supplier Turnmill Proquip Engineering, have client lists which include several local and international mineral resource companies.

Structa principal engineer Jacques Bester warns that, given the rise of mechanisation in the industry and the subsequent increased implementation of advanced technology solutions, the industry requires well trained, experienced engineers to be involved throughout the entire process, including the application and interpretation of the analyses, which is where Structa leverages its experience in the mining industry.

Structa Group supports its subsidiaries in this regard with its analysis and design team, housed within its Structa Konsult business unit, not only serving the group but consulting and assisting various external clients.

Citing Turnmill Proquip as an example, he notes that, in terms of vessel manufacture, standard code rules, which have been based on experimental testing over the last century, do not include provisions for all possible design variations. Therefore, Turnmill Proquip leverages its access to Structa Konsult to generate high accuracy geometric models of every component to verify design details using finite element modelling and advanced non-linear solutions.

Detail design of process equipment is regulated by the Pressure Equipment Regulations and classified according to SANS 347 in South Africa.

The use of advanced analysis techniques is supported by most of the codes in which a typical “protection against failure” evaluation procedure is followed. Essentially, Bester notes that the design of the vessel, for example, should ensure that it does not leak or burst on the first pressure cycle nor should it deform excessively under operating conditions. High-temperature operation and high-cyclic loading are also verified in these design stages.

Advances in software capability and computing capacity facilitated the development of sophisticated structural and flow simulation procedures. Over the last 20 years, this development has matured as the amount of random-access computer memory and model size limits increased, thereby reducing analysis solving times significantly.

Previously, it could take up to 12 hours to complete a complex finite element structural analysis that only takes 20 minutes today. Bester says this increased capability enables engineers to focus on finding the best solution by running multiple simulations instead of latching onto the first model that works.

In addition to reduced time, parametric modelling and scripted execution allow the group to run many design variations as part of its optimisation studies.

The group’s development programme will continue into all the product ranges manufactured within the Structa Group and is available as a system-level design tool for any outside clients.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation