Contractor miner delivers efficient, seamless production

STEADY FLOW Zizwe maintains a steady flow of material, reinforcing its capacity to handle complex mining environments

OPTIMISATION Through Zizwe’s equipment investment, the company aims to lower downtime, reduce costs and enhance safety

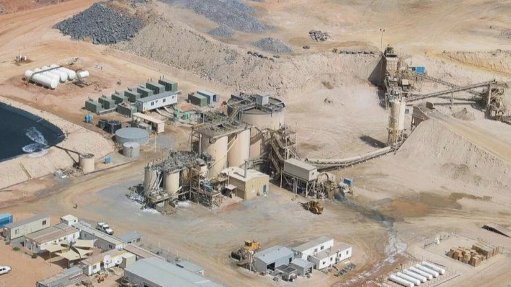

Through an expanded fleet and the introduction of additional services, opencast mining, bulk materials handling, and drilling and blasting services provider Zizwe Opencast Mining is targeting efficient, seamless production at its latest contract operation at a mine near Ogies, in Mpumalanga, which the company started in December 2024.

According to Zizwe, the contract’s early startup laid the foundation for “remarkable progress” as it has consistently exceeded its production targets, with the main plant having come into operation on December 16, 2024.

This project will expand on December 6 this year through the next phase of its development.

Showcasing the company’s commitment to progress, this site was the first to incorporate larger machinery to enhance productivity. Despite some initial challenges, Zizwe’s proactive measures and rigorous operator assessments have ensured optimal safety and efficiency.

In particular, all operators undergo pre- assessments before renewing their certificates of competency, followed by further evaluations to guarantee role readiness.

Zizwe is also expanding its mining contracting equipment fleet, with the introduction of mining equipment manufacturer Caterpillar’s 777-series off-highway trucks and 992-series wheel loaders – both being models that Zizwe has not previously operated, which Zizwe operations manager Colani Bhiya says is a significant milestone.

Through this investment, Zizwe aims to lower downtime, reduce costs and enhance safety while boosting production and machine availability.

Further, through using Caterpillar 773-series off-highway trucks and Caterpillar 986-series wheel loaders, Zizwe maintains a steady flow of material, reinforcing its capacity to handle complex mining environments.

“Our growth trajectory continues, reinforcing Zizwe’s position as an industry leader in safety, efficiency and operational excellence,” Bhiya says.

“We continue to push boundaries, and our latest contract near Ogies, on the R545 road, is a testament to our commitment to excellence,” he adds.

The company’s team comprises a dedicated workforce of 153 professionals operating within a structured 4 × 4 shift cycle, which involves 12-hour shifts — two day shifts and two night shifts, followed by four days off.

The team is led by a site manager and supported by sub-agents, safety officers and supervisors.

Optimised Operations

The company emphasises efficiency as the cornerstone of its operations, noting that discard handling, from the silo to the discard dump, is a crucial process, as any disruption affects overall plant performance.

Further, the company’s coal transport operations from the Ogies project stockpile to the crusher tip are equally vital, requiring a consistent feed rate of 1 500 t/h to 1 700 t/h.

In addition, to mitigate the impact that machine downtime can have on production, Zizwe has established its first dedicated onsite tyre servicing crew to replace its previous reliance on external providers of related services.

This change has “drastically” reduced delays, as the new team now conducts daily checks, pressure readings and proactive maintenance, Zizwe says.

In addition, the company’s transition to new tyre sizes, including 45/65R45 for the site’s fleets and 27.00R49 for the Caterpillar 777 fleet, ensures prolonged tyre life and peak performance.

Further, Zizwe’s expertise now also extends to underground material transportation, which, through its partnership with the mining services provider, enables the company to efficiently bring two-seam and four-seam material to the surface through conveyor systems, before feeding it into a crusher.

“At Zizwe Opencast Mining, we are not just mining, we are shaping the future of the industry, one innovation at a time,” Bhiya concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation