Cummins South Africa on track to rebuild 120 engines at Midrand centre this year

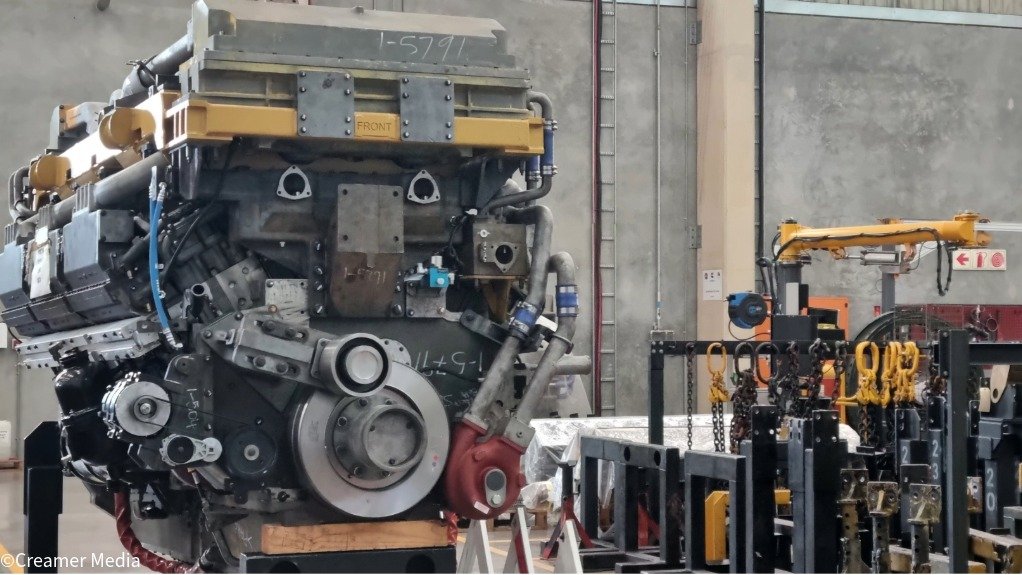

Integrated power solutions company Cummins South Africa is on track to rebuild 120 engines this year at its Master Rebuilt Centre (MRC), in Midrand.

The facility has the capacity to rebuild 14 high-horsepower engines a month and is a key part of the Cummins global group’s network for engine restoration.

The MRC restores engines to their original factory condition with a full warranty.

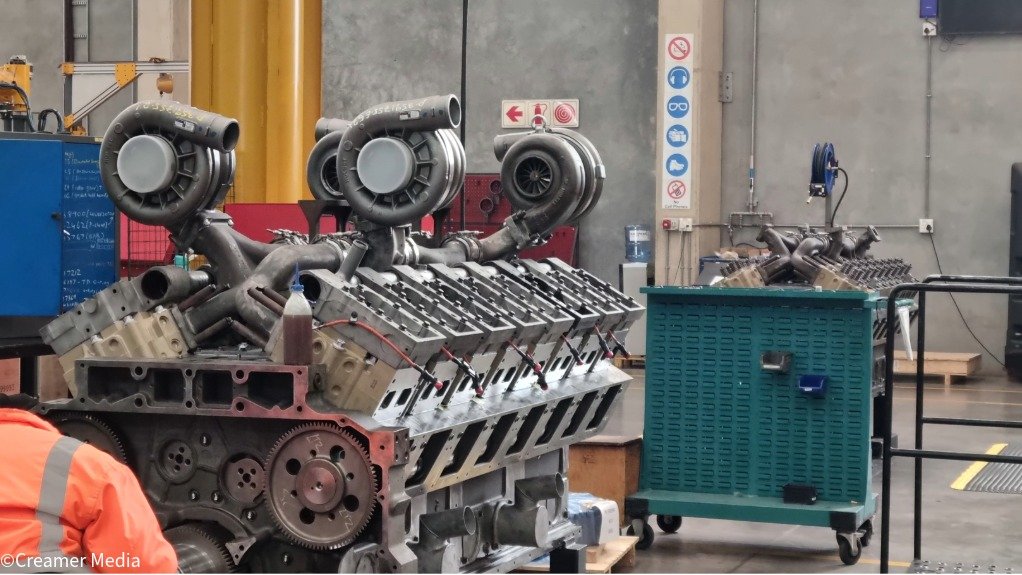

MRC plant manager Aubrey Rambau confirms that engines offer four lifecycles if rebuilt according to world-class standards. Each engine at the Midrand site undergoes dynamometer testing at full power to simulate real operating conditions and ensure the rebuilt engines are fit for heavy industry use in the transport, construction, power generation, marine, mining, defence and agriculture industries.

The MRC is focused on restoring the QST30, K15000, K18000, K2000 E, QSK38, QSK45, QSK50, QSK60 and QSK78 models of engines. The facility primarily supplies the local market, as well as Botswana, Mozambique, Namibia and Zambia.

The bulk of the engines at the facility are “zero hour” rebuilds, meaning they need complete overhauling or remanufacturing to meet or exceed original-equipment manufacturing specifications and resetting its operating time to zero, while the balance comprises fix-as-fail (for specific component failures) and conversion (upfit) restorations.

The rebuild process starts with disassembly, where parts are sorted as unsalvageable and salvageable, followed by cleaning of the salvageable parts. Each part is then inspected to ensure it meets quality standards.

Electronic gauging is used to measure product tolerances. Any parts that do not meet the Cummins specifications are replaced.

The assembly process involves qualified engineers replacing critical parts and performing 150 quality checks. All engines go through a series of rigorous quality and verification tests before shipping.

Cummins South Africa offers a “swing engine” programme to minimise downtime for customers, allowing for a quick engine exchange while the original is being rebuilt, which is critical in sectors such as mining that demand uninterrupted operations.

Moreover, the MRC incorporates a water purification plant and wastewater treatment system that recycles 80% of the water used on site.

As part of its Destination Zero strategy, Cummins South Africa aims to reach net-zero emissions across its facilities and operations. The strategy includes the company reducing waste and ensuring 90% material circularity plans for new products.

Cummins Southern Africa power generation leader Warrick Gibbens confirms the Midrand site recently installed 2 000 solar panels with capacity of between 800 kVA and 900 kVA and nine inverters.

The system caters fully for the site’s power load, with the site expected to install a 1 500 kWh battery energy storage system before the end of the year to store excess electricity generated for cloudy days.

Cummins’ headquarters in Midrand is called the Power Hub, which in 2019 consolidated the company’s various service and sales business units in one strategic location.

The site also hosts Cummins’ Africa Learning Centre that trains artisans on the servicing and repair of specific engine types.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation