DELBA Electrical’s expertise in rewinding a 17 MW stator – a showcase of engineering excellence

Large electrical rotating machine refurbisher DELBA Electrical continues to set new benchmarks in refurbishing of large electrical rotating machines.

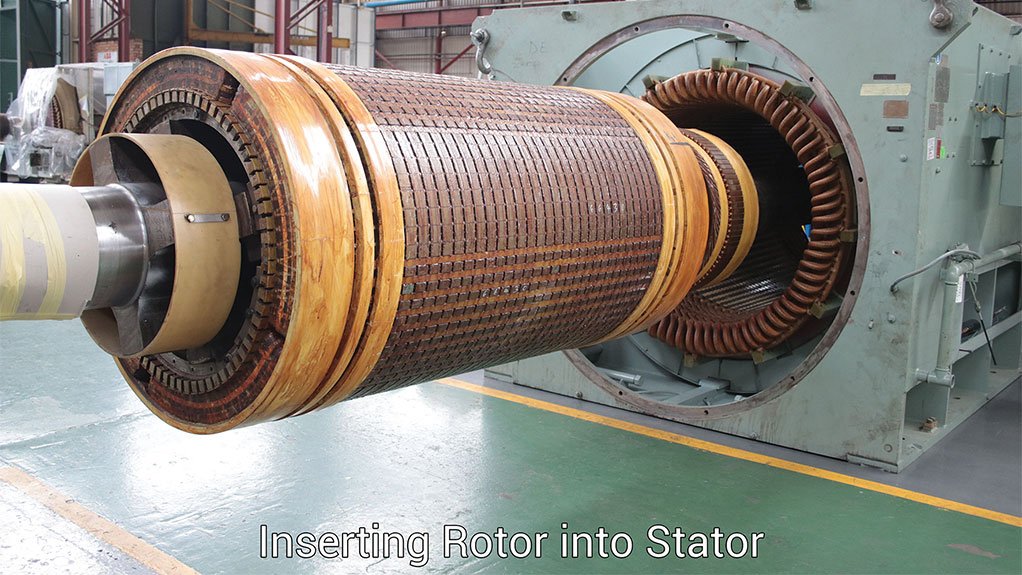

A recent project at its Alrode Large Machines facility involved the manufacturing of a new stator core and complete rewinding of a 17 MW stator and precision balancing of the rotor. This project highlights DELBA’s technical expertise, cutting-edge equipment and commitment to high-quality, energy-efficient solutions in a lead-time of four months.

Rewinding the 17 MW Stator

Rewinding high-power electrical machines demands precision and expertise.

The process included:

- Stripping and assessment: Removing the original stator core with windings and assessing core degradation to determine the necessary repairs.

- Coil manufacturing and insulation: Producing high-grade copper coils with advanced insulation to improve conductivity, thermal resistance and overall durability.

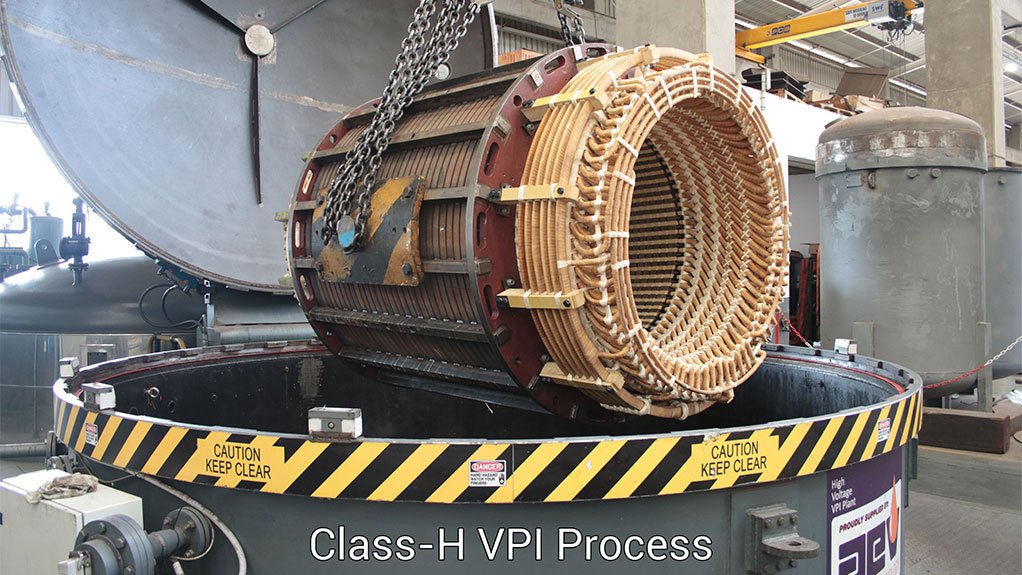

- Precision winding and vacuum impregnation: Expertly installing new coils to ensure uniform distribution, reducing electrical losses. The stator was then sealed using DELBA’s specialised Class H vacuum pressure impregnation (VPI) system, which enhances mechanical strength and insulation reliability.

This process restored the stator to peak performance, improving efficiency and extending its service life.

Manufacturing a New Core with Skew Stator Slot

Manufacturing a new core skew stator slot involves precision engineering to optimise performance and reduce harmonic losses. The process begins with designing and stacking high-grade electrical steel laminations in a skewed configuration to minimise cogging torque and improve efficiency. Advanced welding and bonding techniques ensure structural integrity. Rigorous quality control and testing verify the stator’s electrical and mechanical properties, ensuring it meets operational demands for high-power industrial applications.

- Compression and clamping: Ensuring structural integrity by securely compressing and clamping the laminated core.

- Machining and assembly: The new core was machined to exact specifications and integrated with the stator frame for seamless performance.

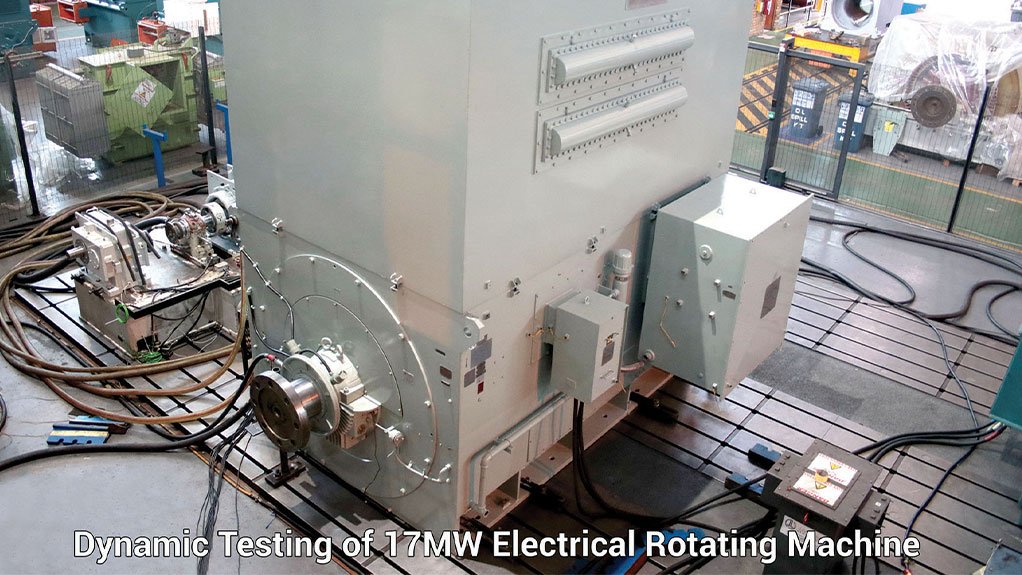

Precision Rotor Balancing

Balancing the rotor is essential to prevent vibrations and mechanical stress, which can lead to premature failures. At DELBA’s Alrode facility, advanced balancing technology was used to achieve optimal performance.

• Dynamic balancing: Detecting and correcting imbalances to reduce mechanical wear and stress on bearings.

• High-precision measurement: Using state-of-the-art sensors to ensure exact balance adjustments.

• Verification and testing: Conducting final tests to confirm stability before reinstallation.

Dynamic balancing ensures smooth operation under high-load conditions.

Successful Incendivity Test

As part of final quality assurance, a successful incendivity test was conducted. This crucial test ensures that the motor operates safely in hazardous environments by verifying that no sparks or ignitions occur under normal operation. The windings are compliant with IEC 60079-7. Passing this test reaffirms DELBA’s commitment to the highest safety standards and reliability in demanding industrial applications.

The manufacturing of a new stator core, successful rewinding of the 17 MW stator, and precision rotor balancing demonstrate DELBA Electrical’s industry leadership in large electrical rotating machine refurbishment.

The Alrode facility, combined with a team of highly trained personnel, ensures that it delivers top-tier solutions to improve efficiency, reliability and longevity.

At DELBA Electrical, they go beyond simple repairs—they optimise machine performance, extend operational lifespans, and contribute to more energy-efficient industrial processes. This project stands as a testament to their expertise, innovation and unwavering dedication to quality in electrical rotating machinery maintenance and repairs.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation