Dry Ice Blasting Applications in Various Industries

Dry ice blasting is a powerful and environmentally friendly cleaning method that is gaining popularity across multiple industries. Unlike traditional cleaning methods that use chemicals or abrasive materials, dry ice blasting utilizes compressed air to propel dry ice pellets at high speed.

The process is non-abrasive, non-toxic, and leaves no secondary waste, making it an ideal solution for delicate and sensitive applications. Here, we explore how dry ice blasting is used in various industries.

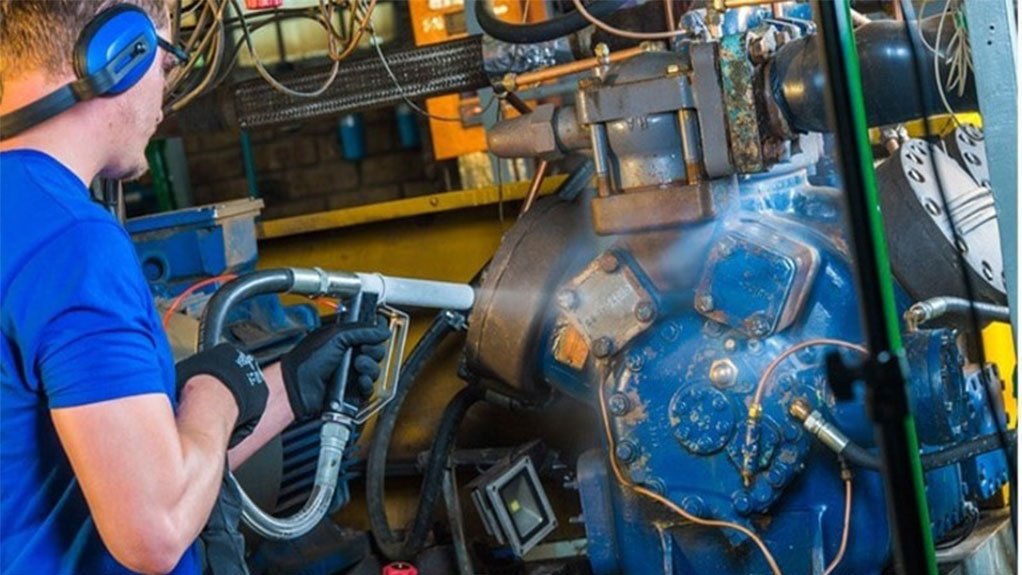

1. Manufacturing and Industrial Equipment Maintenance

In the manufacturing sector, dry ice blasting is widely used to clean machinery, conveyor belts, and production equipment. Over time, grease and residue from production processes accumulate on machinery, reducing efficiency and potentially causing breakdowns.

Dry ice blasting removes these contaminants without damaging sensitive components, eliminating the need for disassembly and minimizing downtime.

2. Automotive Industry

The automotive sector benefits greatly from dry ice blasting, including OEM’s, Tier 1, Tier 2, and Tier 3 suppliers. Traditional cleaning methods often involve abrasive cleaning methods, which can lead to damage of sensitive components resulting in costly repairs.

A dry ice blaster machine effectively removes weld spatter, carbon deposits, oil, and grease without harming surfaces. It is also used in vehicle restoration to clean undercarriages, wheel arches and engine bays.

3. Food and Beverage Industry

Hygiene and cleanliness are paramount in the food and beverage industry. Because dry ice sublimates upon impact, it leaves no water or chemical residue, reducing the risk of bacterial growth and contamination.

The non-toxic and non-abrasive nature of this method means that food safety standards are maintained while reducing downtime associated with cleaning.

4. Aerospace and Aviation

Aircraft maintenance and cleaning require precision and care. Dry ice blasting is used to clean delicate aircraft components without causing damage to the sensitive components.

Traditional cleaning methods involving chemicals can corrode metal surfaces and create hazardous waste. Dry ice blasting eliminates these risks while ensuring that aircraft remain in optimal condition for safe operation.

5. Printing and Packaging

Printing presses and packaging machines accumulate ink, glue, and other contaminants over time, affecting print quality and production efficiency.

Dry ice blasting effectively removes these residues without damaging delicate printing rollers, plates, or sensors. Because the process is dry and non-abrasive, it prevents warping or distortion of printing components, extending their lifespan and improving overall productivity.

6. Electronics and Electrical Equipment

Cleaning electrical equipment presents unique challenges due to the risk of damage from moisture and abrasive materials. Dry ice blasting is an ideal solution for removing dirt and carbon buildup from circuit boards, control panels, and power generation equipment.

Since dry ice sublimates upon contact, it does not introduce moisture thereby reducing the risk of flashover and electrical failures.

Conclusion

Dry ice blasting is revolutionizing industrial cleaning by providing a safe and environmentally friendly solution across various industries. Its ability to clean effectively without leaving behind residue or causing damage makes it a preferred method for businesses looking to improve maintenance processes while reducing costs and downtime.

As industries continue to prioritize sustainability and efficiency, the demand for dry ice blasting is expected to grow, further cementing its role as a leading cleaning technology.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation