Lead removed from electronic blasting products

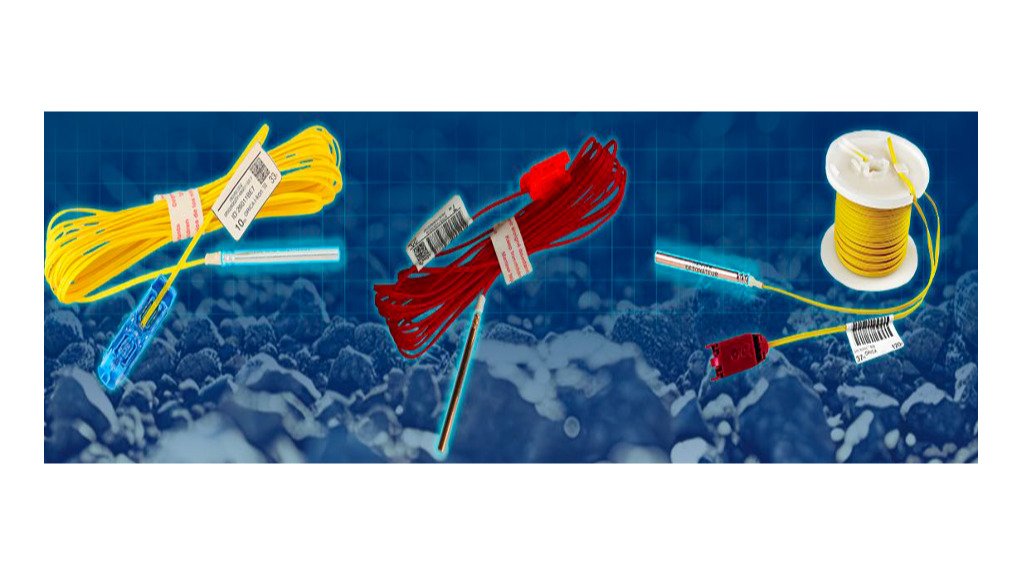

INNOVATIVE PRODUCTS Orica's new, fully lead-free variant will integrate the company's non-primary explosives detonator technology, removing lead azide in the detonator, while the product range will not contain any substances of very high concern

Commercial explosives and blasting systems manufacturer Orica is expanding its lead-free non-primary explosives detonator (NPED) technology through the manufacturing of what it claims is the world’s first lead-free electronic blasting system range, at its plant in Gyttorp, Sweden.

This development follows the successful 2023 introduction of its fully lead-free non-electric detonator range Exel Neo, with early adopters reaping the benefits, according to Orica.

The company services the quarrying sector with explosives and blasting solutions, as well as servicing surface-based coal, metal and iron-ore deposits, in addition to supplying products and services to underground mines, construction, civil engineering, and oil and gas development.

The new, fully lead-free variant will integrate Orica’s NPED technology, removing lead azide in the detonator, while the product range will not contain any substances of very high concern, otherwise known as SVHC, according to the European Union’s (EU’s) Registration, Evaluation, Authorisation and Restriction of Chemicals regulation.

The new lead-free electronic blasting systems range is expected to be available for shipment in Europe by early 2025.

Orica outlines that the lead-free alternative will be made available across the full range of its electronic blasting systems, including the new eDev II Neo, uni tronic 600 and i-kon III Neo, with the same proven performance and results as the current electronic blasting systems range on offer.

Development Endeavours

Orica highlights that the development of the new technology has been underway for several years, with field trials and testing for compliance with the EU’s mandatory conformity marking for goods sold within the European Economic Area to be conducted in the coming months.

“With the expansion of our lead-free NPED technology to our market-leading electronic blasting systems range, Orica takes another step towards a more sustainable future in the industry,” says Orica CTO Angus Melbourne.

He adds that the NPED technology is a testament to Orica’s 150-year history of innovation and commitment to safer and more responsible solutions that deliver positive economic, social and environmental outcomes.

“This is the first time Orica’s electronic blasting systems are being manufactured at our new state-of-the-art facility in Sweden, close to customers in Europe, ensuring supply security and optimisation,” states Orica group executive and Europe, the Middle East and Africa president James Bonner.

The facility, he says, will initially be used to assemble Orica’s standard electronic blasting system’s detonators before it will become the assembly line for the fully lead-free electronic blasting range based on NPED technology.

“Trials with our customers will get underway in July [to] August 2024, and we look forward to continuing to explore how Orica can use innovative technologies to assist our customers achieve their environmental, social and governance goals,” says Bonner.

The NPED product range includes distinct safety and environmental benefits with all lead removed from the production process and thereby from being released into the environment during the application of the products.

Relatedly, Orica is also assessing options for the reduction of plastics in the development of the new lead-free electronic blasting systems, further reducing its environmental footprint.

The company views these efforts as taking another step towards its purpose to sustainably mobilise the Earth’s resources.

The company’s quarrying solutions include those addressing vibration and air blast control, stakeholder management, plant productivity, optimal fragmentation distribution, wall control, shovel/excavator and drill and blast productivity, fume risk reduction, quarry extraction planning, nitrate control in groundwater, reliable and predictable blasting and reduction of drill and blast costs.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation