Engine air filter filter pre-cleaners save coal mine filter costs, downtime

These Sy-Klone engine air filter pre-cleaners can collect and expel 92 to 95% of the ambient dust before it even reaches the engine’s air filter

By installing the Sy-Klone engine air filter pre-cleaner, the mine can significantly extend the service life of its engine air filters

keeping the engine’s air filter cleaner for longer, the pre-cleaner also enhances the performance and fuel efficiency of the engine

This article has been supplied.

Heavy duty cooling and air conditioning specialist Booyco Engineering has installed the innovative Sy-Klone engine air filter pre-cleaners on two drill rigs at a South African coal mine, allowing the customer to save on the costs of both replacement air filters and operational downtime.

“In dusty mining conditions, engine air filters quickly clog and need replacing,” explains Gordon Postma, Sales Manager at Booyco Engineering. “On this coal mine, the drill rig filters were lasting only two or three days before they needed replacing; the customer really needed a more sustainable and cost effective solution.”

This was provided through the supply and installation of four Sy-Klone Series 9000 engine air filter pre-cleaners – two on each drill rig. This leading technology from the US has been proved over decades, and has been continuously refined and improved.

“The result is that these Sy-Klone engine air filter pre-cleaners can collect and expel 92 to 95% of the ambient dust before it even reaches the engine’s air filter,” says Postma. “The scientific design and robust manufacture of the pre-cleaners – using hard polymer plastics for strength – ensures they need little to no maintenance, and can withstand operating in harsh mining conditions.”

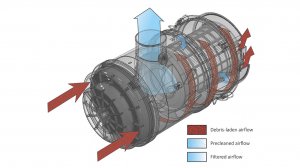

The operating principles of these air pre-cleaners make them remarkably effective, he says. Air enters the underside of the dome design through screened louvers. This prevents any large debris from entering the pre-cleaner which could cause restriction in airflow. Curved particle-accelerator blades push dirt against the sidewall, and strakes – or angled fins – along the interior surface move all heavier-than-air debris towards the ejection slot. This leaves the clean air to continue swirling to the centre of the dome and through to the engine air filter inlet pipe into the engine’s air filter housing through the filter and then into the engine.

“By installing the Sy-Klone engine air filter pre-cleaner, the mine can significantly extend the service life of its engine air filters,” emphasises Postma. “While the savings on the costs of these filters will be important, the real cost to the mine is in drill rig downtime while the filters are changed. The operation will now benefit from better efficiency and productivity due to less maintenance.”

He adds that, by keeping the engine’s air filter cleaner for longer, the pre-cleaner also enhances the performance and fuel efficiency of the engine – as there is less restriction of air moving into the combustion chambers.

“These various benefits add up to a comprehensive solution for the customer, with minimal technical intervention as the pre-cleaners can be readily sized and installed with little disruption to production,” he says.

As a relatively recent addition to Booyco Engineering’s market offering, the Sy-Klone distributorship shows considerable potential in South Africa’s mining sector, as well as in other applications where machinery must operate in high levels of dust. Postma says there is potential for more pre-cleaner installations by this coal mining customer, while a number of other expected installations will soon confirm the product’s efficacy under a range of local conditions.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation