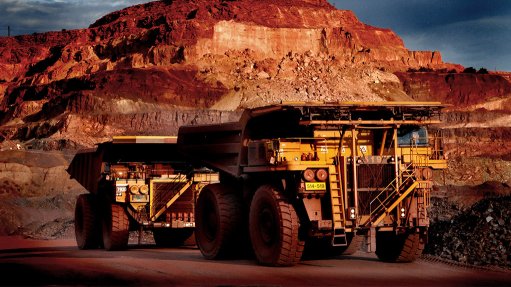

First spodumene concentrate produced at Liontown’s Kathleen Valley

The first spodumene concentrate has been produced at ASX-listed Liontown Resources’ Kathleen Valley operation, in Western Australia.

Following progressive commissioning of the process plant, ore has been processed through the entire crushing, milling and flotation circuit, culminating in first concentrate produced.

With 216 000 t of clean ore already mined to date from the Kathleen’s Corner and Mt Mann openpits, and the primary orezone in Kathleen’s Corner scheduled to be mined starting in late August, Liontown’s stockpile of clean ore is well-positioned for processing, the company said on July 31.

Liontown will now focus on completing the remaining commissioning activities in the non-critical path areas of the plant, concluding construction of critical underground infrastructure such as the paste fill plant and ramping up the process plant to a three-million-tonne-a-year throughput.

Full nameplate production of three-million tonnes a year is expected by the end of the first quarter of next year, with lithium recoveries expected to be optimised over the next 12 to 18 months.

“Two and a half years ago, we set ourselves the ambitious goal of achieving first production by mid-2024. Today, we have achieved it. This is a monumental moment for Liontown and marks our transition from a construction project to a producer of high-quality lithium concentrate. We will commence delivery of spodumene concentrate to our customers in the coming weeks.

“First production signals the start of our ramp-up towards three-million tonnes a year and, in partnership with our tier-one offtake customers, paves the way for us to pursue our long-term strategy to be a globally significant supplier of battery minerals as the world transitions to a low-carbon future," Liontown MD and CEO Tony Ottaviano said.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation