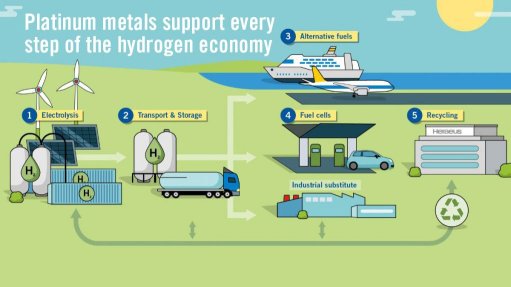

Industries must choose and move on most important hydrogen uses first

Hydrogen can be used in a range of applications and it is important to select the most important use cases for green hydrogen, upon which industries worldwide must then move on.

Multinational gas and chemicals company Linde is focusing primarily on using hydrogen to decarbonise industry and mobility, and as an energy carrier, Linde Clean Energy senior business development manager Timothy Carmichael said in an address at the recent Hydrogen Africa conference.

"We focus on heavy-duty transport as a first-mover, as a way of addressing initial challenges such as payload disadvantages, while the refueling times for hydrogen are good. This approach will differentiate the offering and accelerate the mobility market for hydrogen use," he said.

Further, from an energy vector perspective, ammonia and methanol were both highly traded markets and low-carbon hydrogen, which included blue and green hydrogen, low-carbon ammonia and low-carbon methanol, could be a mechanism to accelerate the transition, he said.

"One of the most interesting and most accessible markets is around industrial decarbonisation. We see lots of potential there, as the steel industry is a strong consumer of electricity and has a challenge to meet its decarbonisation targets.

"As an industrial gas company, we are involved in decarbonisation efforts, including more than 100 installations using oxygen-enriched feeds for steel mills, which reduce their emissions and their fuel requirements.

"Decarbonising industries, similarly, requires that we understand the appropriate uses of hydrogen and can roll them out to many companies," Carmichael said.

However, using hydrogen to decarbonise steel production was currently unrealistic given the green hydrogen volumes required and the lack of economies of scale, and it would be an area of investment further down the road, said industrial equipment company Siemens Energy Southern Africa business development head Mark van Antwerp.

"However, we can displace emissions from transportation by using renewable energy as a way of generating economies of scale and bringing volumes to the market that are realistic.

"For us [as Siemens Energy], we are focused on ensuring that our gas turbines are ready to use hydrogen. By 2030, all our turbines will be 100% ready to use hydrogen gas, but the gas turbines that we installed in Mozambique recently are already 75% ready to use hydrogen," he said.

The company was also upscaling its production of hydrogen electrolysers, as more industries moved to decarbonise operations, and a 1 GW factory should be operational in November. Siemens Energy aimed to increase its production of electrolysers by about 1 GW a year, he added.

Meanwhile, Linde currently derived $3-billion of its yearly revenue from sales of hydrogen and a key differentiator for the company was that it owned and operated 80 electrolysers used for hydrogen production, said Carmichael.

"We are now trying to take advantage of our experience to increase capacity and we have scaled up our electrolyser production facilities, including proton exchange membrane electrolysers, to 24 MW a year.

"We have experience across the hydrogen value chain, including steam reforming, electrolyser technologies and ammonia/methanol synthesis. We are also making investments into assets to support the transition," he added.

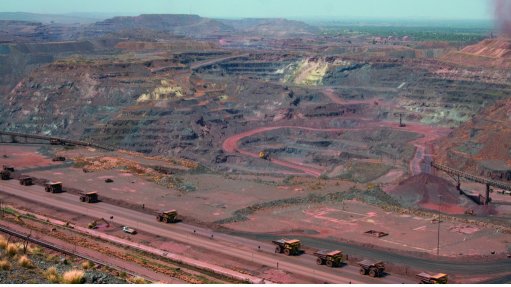

Meanwhile, Australia-based resources and energy company Fortescue aimed to displace around 800-million litres of diesel by 2030, said Fortescue Africa president Bruh Terfie.

"We need the [hydrogen] molecule. We run 200 locomotives and need green hydrogen and ammonia to decarbonise these applications. However, we have built up a global project pipeline, and started in Australia, the Middle East and North Africa, as well as in the US and South Africa.

"In Norway, we have a 600 MW project that aims to produce green ammonia for export to Europe. We also have 80 MW of hydrogen projects in the late stages of development in Kenya and Namibia," he said.

"Further, we acquired a UK company, Williams Advanced Engineering, to have the ability to produce our own batteries. We are also producing our own electrolysers and are building a 2 GW facility in Gladstone, Queensland.

"We are taking a full value chain approach wherein we are combining synergies, such as our need to produce green iron-ore, and producing hydrogen at large scale will allow us to decarbonise and supply others [with green hydrogen]," Terfie said.

Fortescue aims to decarbonise its Scope 1 and 2 emissions by 2030 and its Scope 3 emissions by 2040.

Additionally, it was important to focus hydrogen efforts on those sectors that did not have alternatives to using green hydrogen to decarbonise, such as heavy industry, shipping and aviation, he said.

"For example, our project in Kenya aims to produce green ammonia to produce nitrogen-based fertiliser. Kenya imports one-million tons of fertiliser a year and Tanzania imports two-million tons of fertiliser a year.

"Producing green ammonia locally will be a game-changer and will support food security. This focus on increasing production and productivity is the lense Africa needs to adopt when moving on green hydrogen opportunities," he emphasised.

"The race to green hydrogen is a global race and most countries are thinking how they can participate. Some have more resources to accelerate production of green hydrogen and its derivatives within their own borders," said development finance institution International Finance Corporation (IFC) innovation and business development climate business senior manager Diep Nguyen-Van Houtte.

"Countries and industries need to think hard about investing in new technology and spending money. However, these investments require incentives and some countries do not have the financial resources to offer incentives.

"The role of governments is very important and regulations and decarbonisation targets are required, as all countries are under pressure to get to net zero. Countries need greater capacity to institute legal changes and regulations ahead of the green hydrogen transition," she said.

"Further, five of the top ten priority green hydrogen projects that the IFC is investing in, are in Africa," she highlighted.

*The Hydrogen Africa conference was held in Johannesburg on September 28 and 29.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation