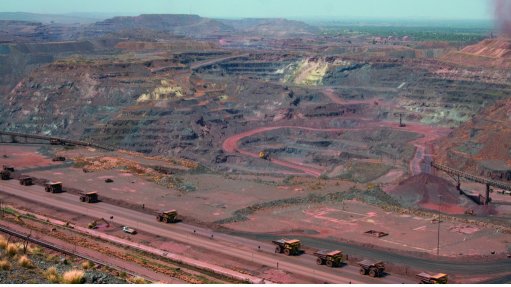

Kola potash project, Congo-Brazzaville – update

Photo by Kore Potash

Name of the Project

Kola potash project.

Location

Sintoukola basin, Congo-Brazzaville.

Project Owner/s

Kore Potash and Summit Consortium.

Project Description

Kore Potash completed a definitive feasibility study (DFS) in 2019, in which it proposed a production estimate of 2.2-million tonnes a year of muriate of potash (MoP). This is based on a mine life of 33 years comprising 23 production years, exploiting ore reserves of 152.4-million tonnes and 9.7-million tonnes of inferred mineral resources, and an additional ten production years exploiting 70-million tonnes of the remaining inferred mineral resources.

Total MoP production has decreased from 2.2-million tonnes a year in the 2019 DFS to 2.14-million tonnes a year in the 2022 optimisation study.

The optimisation study estimates a 31-year mine life, which includes 25 production years exploiting ore reserves of 152.4-million tonnes, together with 9.7-million tonnes of inferred mineral resources, and an additional six production years exploiting 49-million tons of the remaining inferred mineral resources.

The Kola orebody is planned to be mined using conventional underground mechanised methods, extracting the ore within ‘panels’ using continuous miner equipment of the drum-cutting type. Mine access will be provided through two 270-m-deep vertical shafts, each 8 m in diameter. The shafts will be sunk near the centre of the orebody.

Underground access will be provided through equipping the intake shaft with a hoist and cage system to transport persons and material.

The exhaust shaft will be equipped with a pocket lift conveyor system to continuously convey the mined-out ore to the surface.

Ore from underground will be transported to the process plant using a 24-km-long overland conveyor. A conventional potash flotation plant with a maximum design capacity of 2.24-million tons a year of MoP has been designed for the project. As a result of the low insolubles content, no separate process circuit will be required to extract insoluble material. The final MoP product will then be transported 11 km using a conveyor belt from the process plant to the marine export facility at the coast.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

The optimisation study estimates an ungeared after-tax net present value (NPV), at a 10% discount rate, of $1.62-billion and an internal rate of return (IRR) of 20%, compared with an NPV, at a 10% discount rate, of $1.42-billion and an IRR of 17.2% in the DFS.

Capital Expenditure

The capital cost of the project is estimated at $2.1-billion.

Planned Start/End Date

The construction period has been reduced from 46 months in the DFS to 40 months in the optimisation study.

Latest Developments

The Summit Consortium has advised that the financing proposal for the total construction cost of the project will be provided for Kore within six weeks of the engineering, procurement and construction contract terms being finalised.

Kore Potash maintains that the consortium members can provide the required financing for the construction of Kola, and that pursuing this financing opportunity remains the best path forward for Kore Potash’s shareholders.

Key Contracts, Suppliers and Consultants

Met-Chem DRA Global (mineral resource estimate); and SRK Consulting (environmental- and social-impact assessment).

Contact Details for Project Information

Tavistock, on behalf of Kore Potash, tel +44 207 920 3150 or email kore@tavistock.co.uk.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation