Lucara, UMS commemorate final production shaft blast, safety milestones at Karowe Mine

Toronto-listed Lucara Diamond, along with its shaft sinking contractor in the project, United Mining Services (UMS), on September 4 hosted a final production shaft blast ceremony and safety milestone celebration for the Karowe diamond mine, in Botswana, as it readies for the next stage of mine development.

An event was held to celebrate the milestone of the last blast for the 770-m-deep production shaft, as is common practice in the industry owing to the unpredictable and risky nature of shaft sinking, Lucara president and CEO William Lamb explained.

He highlighted that this was achieved with a ”remarkable” 2 000 lost-time injury- (LTI-) free days, since work began over five and a half years ago, and nearly 5.72-million LTI-free hours.

Lamb acclaimed that, simultaneously, the company was able to achieve sinking through difficult conditions including two aquifers, sandstone and mud stones to reach the bottom of the shaft.

“The 2 000 days that you see – start as you mean to finish. . . . Two thousand days LTI free is how we’ve started. This is how we have to carry on. It is not just an achievement, it is now the foundation on which we will drive the rest of the project,” he emphasised.

The safety performance was attributed to an emphasis on implementing a safety culture that included all stakeholders, as well as myriad of initiatives, campaigns, supervisions and systems being implemented, UMS CEO Digby Glover said.

This included a SafeStart (BBS) and a comprehensive ‘stop and fix’ process. The strong safety culture is led from the most senior levels, but is expected from all employees and contractors, he explained.

UMS’s mine hoists and lashing gear has modern and advanced control and safety systems, UMS technical director Murray Macnab highlighted.

UMS also invested in a large crew of hoist experts to ensure consistent quality and knowledge-retention on hoist-specific shaft sinking programmable logic controller safety systems, designed in-house by UMS.

Lucara also provided a ‘mock-up’ on-site training unit to undertake initial and refresher training of lashing operators.

Karowe’s current openpit reserve is expected to be fully depleted by first quarter 2026 and the underground project (UGP) is designed to extend the life of the mine and access the highest-value portion of the orebody where many of the world’s largest diamonds have been recovered.

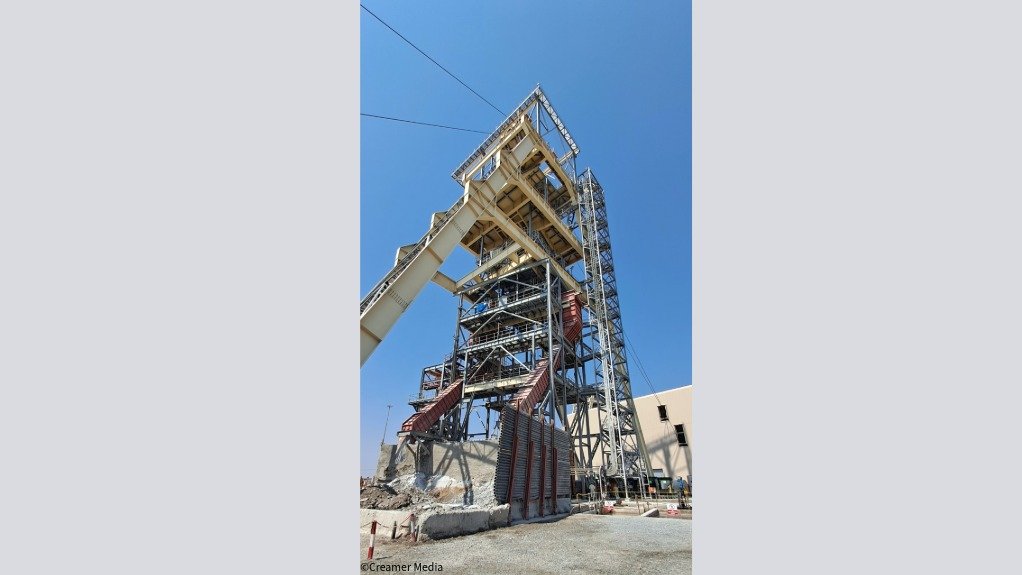

Access to the underground mine will be from the 770-m-deep production shaft, which is 8.5 m in diameter. A second shaft will serve as the main exhaust route and emergency secondary egress for the mine.

UMS’s involvement in the project entails the twin shaft sinking, equipping and infrastructure work for the mine. It has been involved in the project since the final stages of the feasibility stage, in 2019, with the initial role of reviewing the shaft component, preparing designs for early works and initiating long-lead procurement, Glover explained.

He highlighted that completion of production shaft sinking was delivered ahead of contractual schedule, and notably, without a single LTI, as alluded to.

Project site construction work started on February 3, 2020, the first blast for the presink of the production shaft occurred on September 27, 2021, the main sink started a year later and the last blast in the shaft was on July 28 this year at 770 m below surface.

Shaft sinking has created employment for people from Letlhakane and across Botswana, and it has also fostered high-performing teams with rare and valuable shaft sinking skills.

“These skills can serve ongoing operations or can contribute to the broader growth of Botswana’s mining economy by being deployed on future underground projects,” Glover acclaimed.

Achieving this means that the next stage of development can proceed, that is, shaft equipping, Glover informed, noting that this is already under way with steelwork already being delivered to site.

A lengthy process, he said that milestones being targeted in this process include commissioning and licencing the conveyances to allow for people to be transported efficiently down the shaft; as well as commissioning the rock hoisting system to allow for underground production to start being brought to surface.

An operational readiness programme is also under way for when the Karowe underground project reaches commercial production, which is expected in 2028.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation