Mill equipment advances essential for industry

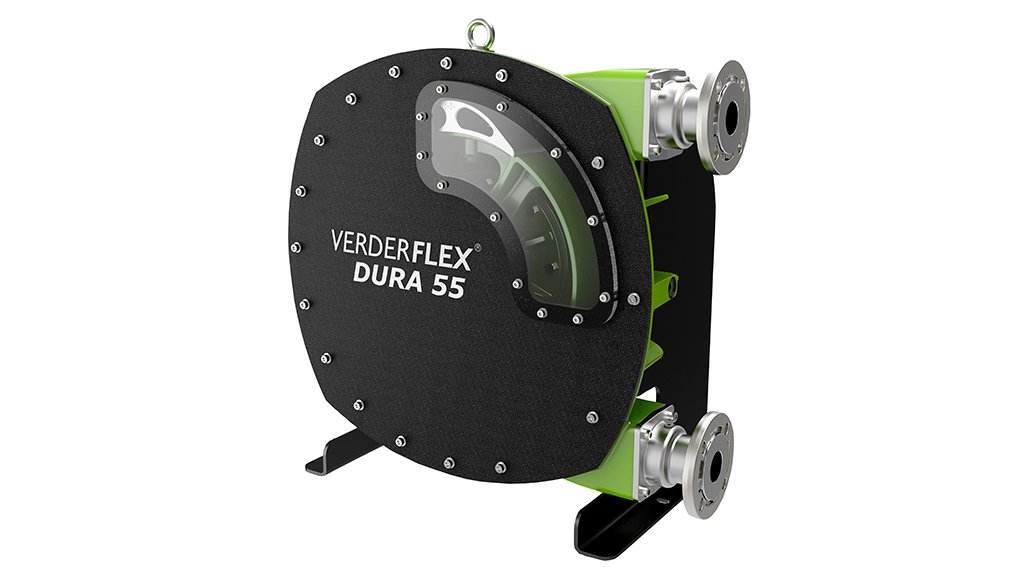

ALLEVIATING THE DEFECTS Sucrose losses can be significantly reduced – if not mitigated altogether – if the correct advanced and integrated pumping solution is used

With the local sugar industry being more than 150 years old, advances in equipment critical to the milling process add “immense value”, as they improve the operational efficiency potential of the sugar mills, says industrial equipment supplier Verder Pumps MD Darryl Macdougall.

“The sugar industry is a key economic contributor to the South African economy in terms of gross domestic product (GDP) contributions and export earnings. Factored into this is the domino effect of socioeconomic benefits in job creation and local economic activities, which can be tracked back to industrial activities that are linked to farming, milling and manufacturing.”

Macdougall explains that a standard sugar cane milling process comprises eight steps – cane preparation, sucrose extraction, raw-juice clarification, filtration, evaporation, syrup clarification, crystallisation and centrifugal separation.

Therefore, processing sugar cane puts great demand on the machinery, with pumps, pipes and valves having to withstand high temperatures and pressure.

Generally, loss of sucrose – a sweet crystalline dextrorotatory disaccharide sugar that occurs naturally in most plants and is obtained commercially especially from sugar cane or sugar beets – is experienced at each stage, although to varying degrees.

As such, having a poorly designed pump system can lead to higher rates of sucrose losses, as well as higher power consumption.

“The wrong pump system can also lead to premature wear or failure of components in the milling and processing production line – as this is not isolated to the pump itself – and can impact on instrumentation, piping, valves and ancillary equipment,” he tells Engineering News.

This, he says, can lead to higher risk of a complete mill stoppage, or excessive breakdowns, that can also increase the risk to personnel, because of emergency repairs that will have to be carried out in addition to routine planned maintenance.

Notably, any of these possible scenarios are guaranteed to hamper operational efficiencies and production outputs – including a possible increase in labour costs and the spare parts inventory – consequently resulting in increased operational expenses, Macdougall highlights.

He adds that these factors affect the industry negatively, as they could lead to companies not being able to produce the sugar tonnage required to affect the GDP positively.

However, sucrose losses can be significantly reduced – if not mitigated altogether – in the event of the correct advanced and integrated pumping solution being used.

“The correct pumping solution that is seal-less, leak free and suitable for pumping sensitive, abrasive or highly viscous fluids will bode added benefits in energy efficiency and safety, thereby supporting operational efficiency objectives for the mill,” Macdougall points out.

He also notes that the local industry, both upstream and downstream, contributes about 6% to the country’s total agriculture output and is estimated to be worth R14-billion. The value of yearly sugar cane production of about 20-million tons averages about R7.7-billion a year.

Meanwhile, navigating the technical obstacles of selecting the right pumping solutions for specific applications can be complex.

Consequently, sugar millers and manufacturers need to look to a trusted and reputable brand – such as Verder Pumps – that can offer a range of pumping solutions, the company says.

“Our solutions are long-lasting, cost-effective and energy efficient because they are 100% fit-for-purpose for each application at every step of the sugar cane milling process,” concludes Macdougall.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation