Momentum behind collision prevention on mines

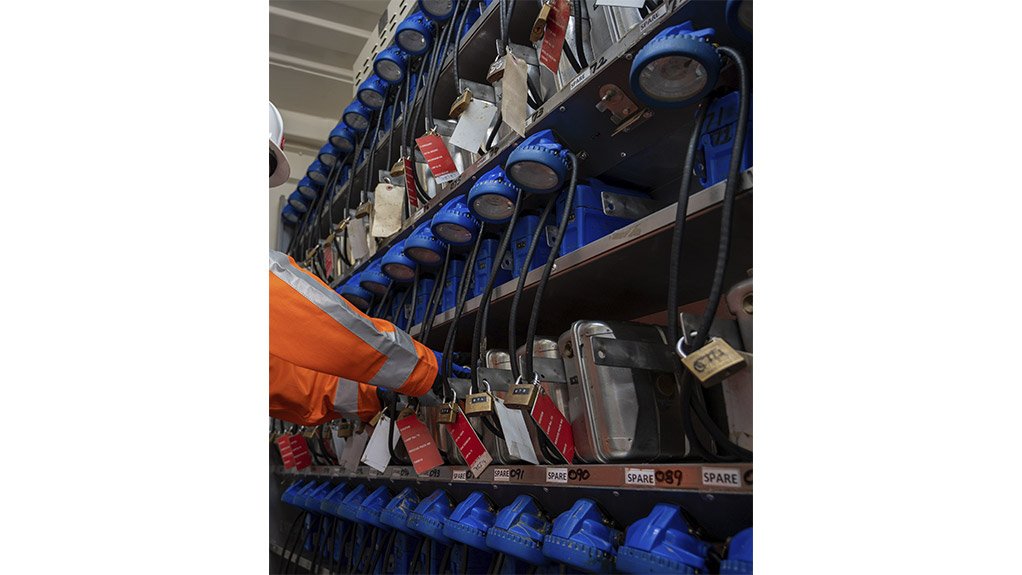

The take-up of Booyco PDS technology has seen over 6500 sets of mining vehicle equipment installed across

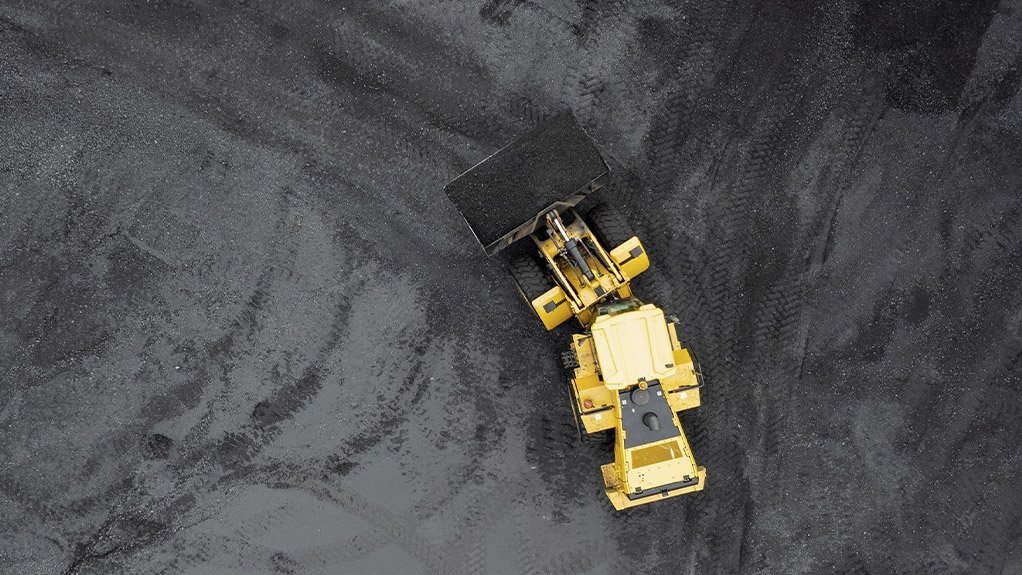

All mining operations must observe strict health and safety regulations to mitigate the risk of collisions between pedestrians and vehicles and between vehicles.

A PDS or CPS solution is a potentially game-changing safety device that will improve workers' wellbeing in their daily working environment.

While Proximity Detection Systems (PDSs) have been around for little more than 15 years, the offerings on the market today are streets ahead of what was first made available; this complexity has to be well managed by the sector if the solutions are to be effective.

“The technological developments – combined with the various legal requirements – have led to quite a complex playing field,” says Anton Lourens, CEO of Collision Prevention System (CPS) pioneer Booyco Electronics. “The evolution of PDS into more functional CPS technologies has only been possible through intense collaboration between mines, third-party suppliers and original equipment manufacturers (OEMs).”

He notes that in South Africa, the Minerals Council has taken a proactive role in facilitating industry cooperation, supported by the leadership of mining companies which are actively pursuing the implementation of these systems even while regulations are still evolving.

“There has been global collaboration in PDS and CPS systems for many years through the Earth Moving Equipment Safety Round Table (EMESRT) – an ongoing process in which Booyco Electronics partakes,” he says. “It is encouraging to see the commitment at a local level too, which ensures that CPS technology has a real impact on mine safety.”

He highlights that CPS suppliers are continuously driven to improve the functionality and performance of their systems. As importantly, those systems must safely integrate with the OEM machines in a systematic and sustainable way so that progress is based on a mutually agreed framework.

“A key step forward in this regard was the industry’s adoption of the ISO 21815-2 standard, which facilitates better integration between third party CPS suppliers and OEM equipment,” says Lourens. “By defining how this equipment should interface with each other, the standard creates a solid safety foundation for progress.”

The basis of effective collision prevention remains the identification of ‘significant risk’, he argues; this is also a legal requirement in terms of the Mine Health and Safety Act. Only once a mine’s specific risks have been well defined, can a suitable CPS strategy be devised and implemented.

“This also makes the choice of technology more rational, as the mine will be clear about what it wants the CPS solution to achieve,” he says. “It is unrealistic to expect any single technology to provide a ‘silver bullet’ for risk management.”

CAPTIONS

MOMENTUM PIC 01 : All mining operations must observe strict health and safety regulations to mitigate the risk of collisions between pedestrians and vehicles and between vehicles.

MOMENTUM PIC 02 : Putting a PDS or CPS solution in place in a mining operation requires a proper risk assessment to be done.

MOMENTUM PIC 03 : A PDS or CPS solution is a potentially game-changing safety device that will improve workers' wellbeing in their daily working environment.

MOMENTUM PIC 04 : The take-up of Booyco PDS technology has seen over 6500 sets of mining vehicle equipment installed across southern Africa and more than 56 000 pedestrian supplied with PDS equipment.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation