Multotec’s Middelburg branch adapts to coal’s evolving demands on South Africa’s highveld

This article has been supplied.

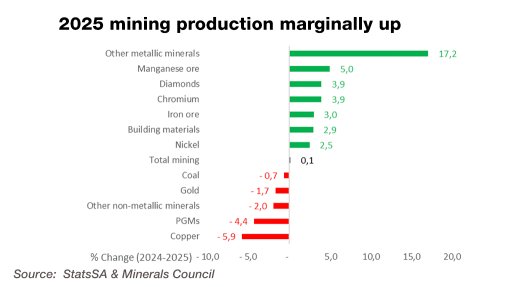

As South Africa’s coal industry navigates ongoing operational and environmental challenges, there is a renewed emphasis on practical, regionally focused support models developed by companies serving the mining sector, particularly coal. Mpumalanga province lies at the heart of this industry, contributing approximately 81% of the nation’s coal production and housing most of its active mines. To provide effective and timely support, establishing a service hub near these key Highveld mines is vital for maintaining operational efficiency and responsiveness, and Multotec is meeting this need with its Middleburg branch.

The importance of proximity for coal mine operations

Mike Meiring, Middleburg Branch Manager at Multotec, explains “Coal mines are complex, high-stakes operations that require a continuous flow of equipment and services to maintain productivity and safety. When issues arise, whether due to wear and tear, process bottlenecks, or sudden failures, having reliable, nearby support can significantly reduce downtime, prevent costly delays, and optimise overall plant performance. The ability to quickly access critical components, technical expertise, and tailored solutions is essential for mines striving to meet production targets, improve safety outcomes while adhering to environmental standards. These factors are increasingly vital in today’s evolving coal mining landscape.”

Regional response and local impact

Located at the centre of key coal mining hubs such, Ogies, Phola, Kriel, and Secunda, Multotec’s Middleburg branch plays a vital role in keeping mines operational. Quick deployment of technicians and critical spare parts helps reduce downtime, supports prompt repairs, and enhances first-time fix rates. Intelligent inventory management ensures essential components are readily available, allowing mines to respond swiftly to maintenance needs.

By employing local technicians not only accelerates troubleshooting but also fosters stronger ties with the community, creating a sustainable support network aligned with regional economic development.

Applied engineering solutions for improved efficiency

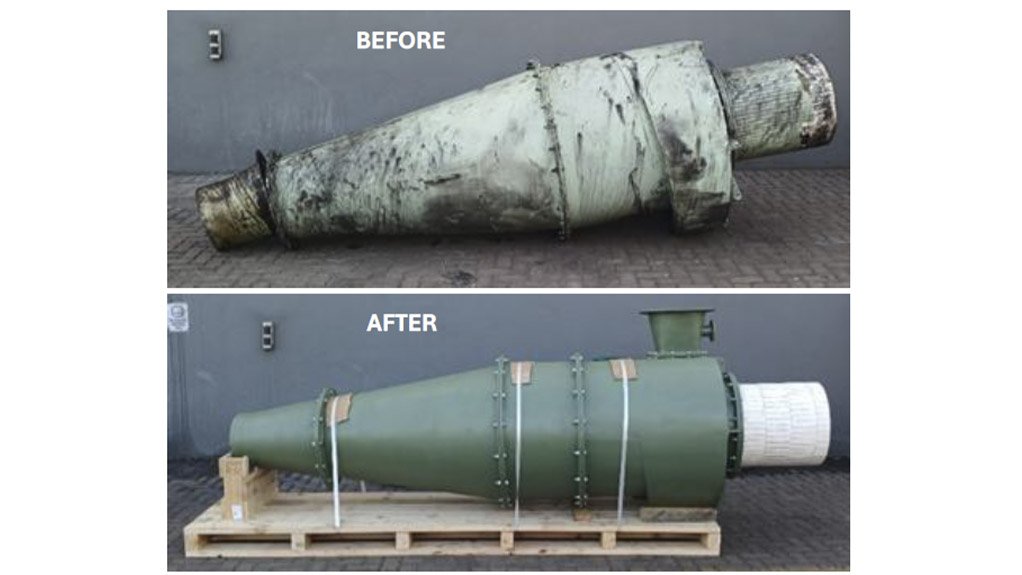

Coal mines face numerous process bottlenecks, that require tailored equipment solutions to optimise performance and reduce downtime. Custom configurations, such as cyclone designs that stabilise separation processes during variable conditions, help maintain product quality and minimise magnetite losses.

Meiring adds, “Having access to spares is essential. Strategic inventory of components, including ready-to-use spigots and vortex finders, is crucial for ensuring continuous plant operation by minimising downtime. Innovative screen deck maps, developed from fundamental principles, enable maintenance teams to predict wear and plan replacements efficiently, reducing emergency downtime from days to hours. The use of impact and abrasion-resistant hybrid materials extends equipment lifespan, while well-sized pump systems with proactive monitoring ensure continuous operation. On-site 3D scanning and custom liner kits further enhance wear management, allowing scheduled maintenance to be performed more efficiently.”

Data-driven systems and maintenance approaches

Effective coal operations maintenance relies on detailed data collection and analysis. Techniques such as layered magnet systems and automated diversion controls allow for quick detection and address tramp-metal issues.

Central to this approach is Multotec’s digital web-based monitoring platform, Hawkeye, which gathers historic maintenance data to enhance future maintenance planning and performance. By allowing predictive maintenance and smarter planning, it helps mines identify long-term trends, address root causes, improve reliability, reduce unexpected failures, and optimise overall equipment performance.

Partnership model and performance

Meiring highlights, “Rather than simply providing parts, Multotec integrates with customers’ teams to co-author KPIs, conduct quarterly reviews, and align incentives to reliability, cost, and overall equipment effectiveness. Contracts based on cent-per-ton performance are becoming common, allowing clients to stabilise operational costs even during turbulent market swings.”

The next wave of innovation

Current projects include fast diagnostics of flowsheet equipment, pilot integration of predictive dashboards, and expanded inventory management. The branch’s blend of technical service, fast response, and embedded local knowledge is seen as increasingly valuable as coal sector stakeholders seek cost stability, data-driven decision-making, and adaptation to new environmental and production standards.

In a shifting coal landscape, Multotec’s Middelburg branch may be providing more than spare parts, it is offering a window into a service model focused on continuous improvement, transparency, and local engagement.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation