NICO gold/cobalt/bismuth/copper mine project, Canada

Name of the Project

NICO gold/cobalt/bismuth/copper mine project.

Location

Northwest Territories, Canada.

Client

Fortune Minerals.

Project Description

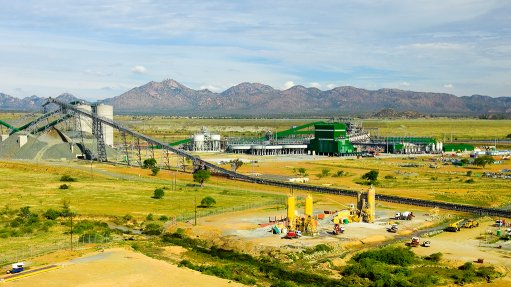

The proposed NICO mine is located 50 km north of the Tlicho community of Whati and 160 km north-west of Yellowknife, in Canada’s Northwest Territories.

The NICO deposit contains openpit and underground proven and probable mineral reserves totalling 33.1-million tonnes containing 1 085 000 oz of gold, 82.3-million pounds of cobalt, 102.1-million pounds of bismuth and 27.2-million pounds of copper. At the planned mill throughput rate of 4 650 t/d of ore, the mineral reserves will sustain operations for 21 years.

Openpit methods will be used, with underground ores contributing 22% of the mill feed during the second year of operations. The openpit part of the mine will be a conventional truck-and-shovel/loader operation, accomplished in four phases at an average waste-to-ore strip ratio of 3.0:1.

The underground portion of the mine will be mined by a contractor using retreat blasthole open stoping, providing access for gold-rich, higher-grade ores.

The ore will be processed in two stages at the NICO site and Saskatchewan metals processing plant (SMPP). At the NICO site, an average of 4 650 dry tonnes a day of ore will be processed in a crushing, grinding and flotation concentrator to produce about 180 t/d of wet bulk concentrate.

The bulk concentrate will be bagged and transported by truck to Hay River, Northern Territories, for transfer to rail and delivery to Fortune’s proposed SMPP on the CN main line, near Saskatoon, where the concentrate will undergo additional grinding and flotation to produce separate gold-bearing cobalt and bismuth concentrates.

The cobalt concentrate will be processed using pressure acid leach in an autoclave to dissolve the metals. The pregnant solution that is produced will be treated with lime sequential neutralisation to remove impurities and then with sodium carbonate to precipitate cobalt carbonate. This carbonate is releached in sulphuric acid to a produce cobalt sulphate solution, which is purified further through ion exchange. The cobalt is precipitated using electrowinning to cobalt cathode that is 99.8% purity.

Alternatively, the cobalt that is present as a sulphate in solution can be processed further through solvent extraction to remove metal impurities, followed by crystallisation, to generate 20.9% cobalt sulphate heptahydrate crystals.

Copper that is removed from the cobalt solution during neutralisation is releached in acid and precipitated onto iron fines as a copper metal precipitate or ‘cement’.

The bismuth concentrate is treated using atmospheric acid leach, followed by electrowinning to produce 99.5% bismuth cathode, which is melted and poured to produce 99.99% bismuth ingots.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

Not stated.

Value

C$589-million-plus working capital.

Duration

Not stated.

Latest Developments

The two-year construction of the NICO project could start in early 2019 on receipt of the project financing and remaining regulatory approvals, which are expected later this year.

“The environmental-impact assessment (EIA) approvals have been received for the mine and concentrator in the Northwest Territories, and the refinery in Saskatchewan. The company has also received the major mine permits,” Fortune Minerals president and CEO Robin Goad has told Mining Weekly.

He says the Nico project has had previous expenditures of more than C$120-million and the company has engaged advisory firm PricewaterhouseCoopers to arrange the project financing based on a combination of debt, equity and strategic partnerships.

Goad says the feasibility study is being prepared by three mining engineering consulting companies – Hatch, P&E Mining and Micon International – and is expected to be completed in the second quarter of this year. The only significant outstanding permit is the zoning change in Saskatchewan and this is in progress.

The new feasibility study in progress is also assessing an increase in the process rate of about 30%, which will also increase the capital cost of the development; however, the cost is expected to be in line with the scale-up in production.

Goad explains that Fortune Minerals is sufficiently financed to support the project finance process, but will need to secure the capital for mine and refinery developments. “Securing an asset-level strategic partner will unlock the financing hurdle and also simplify the terms for any applicable debt facility.”

Confidentiality agreements on strategic partnerships have been executed with several companies, including automotive original-equipment manufacturers, battery companies, commodity traders, mining companies and private-equity firms.

The preferred partner will have a strategic need to procure a reliable supply of cobalt sulphate battery chemicals.

The feasibility study is nearing completion to support negotiations with potential strategic partners interested in securing a reliable and ethical supply of battery-grade cobalt sulphate from a Canadian vertically integrated source with supply chain transparency.

Production could start in 2021, when the world’s automotive companies will intensify the mass production of electric vehicles, Goad has indicated.

He is concerned about the typical timelines involved in developing new mines in Canada – between ten and 20 years – which is often too long for most investors. The regulatory processes and timelines for permitting need to be reduced to allow for significant new investments in the country’s mining sector, Goad has said.

“The EIA process for the NICO project took seven years to complete and that is, frankly, too long. The EIA and regulatory processes need to be streamlined and made more efficient and cost effective.”

Key Contracts and Suppliers

None stated.

On Budget and on Time?

Not stated.

Contact Details for Project Information

Fortune Minerals investor relations manager Troy Nazarewicz, tel +1 519 858 8188, fax +1 519 858 8155 or email info@fortuneminerals.com.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation