No ‘mucking about’ with safety for UMS

SAFETY FIRST UMS CEO Digby Glover says it is now possible to sink shafts without accidents, owing to innovations of equipment and methodology

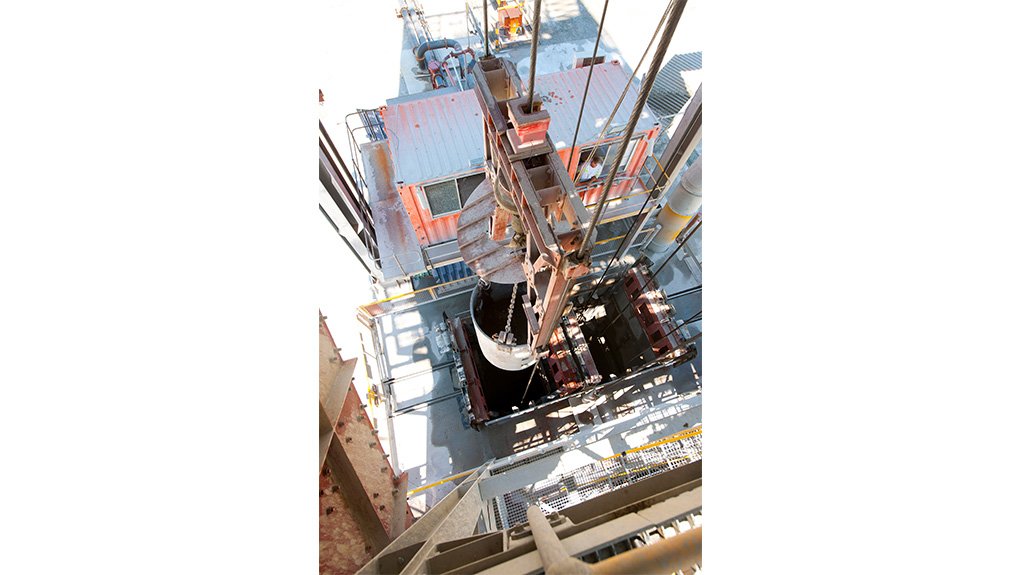

MUCH ADO ABOUT MUCKING To eliminate risks, UMS is now using vertical shaft muckers and shaft drilling jumbos for many projects

Shaft sinking company United Mining Services (UMS) boasts shaft sinking innovations that the company is applying across its international projects, says CEO Digby Glover.

Throughout its 60-year history, UMS has helped its clients extract value from the world’s most challenging ore bodies. Over the last six decades, the organisation’s shaft sinking division has gained “invaluable” experience and expertise from sinking more than 170 000 m of vertical shafts globally.

Glover says shaft sinking has become more mechanised, whereby removing people from the shaft bottom is the driving force behind most innovations, and this objective has been met for almost all aspects of the sinking cycle.

“Shaft sinking has been evolving for years as hazards are identified and addressed through design and elimination. UMS is continuously striving to make the sinking process as safe as possible, and zero harm is the absolute objective for all our projects.”

The cactus grab, for example, is used for lashing or mucking of blasted material and has been widely used in the sinking process globally since its introduction in South Africa in the 1950s.

The cactus grab has a high loading rate, but is associated with safety hazards owing to various heavy operations that occur simultaneously with workers nearby, he says.

To eliminate risks, Glover says UMS is now using vertical shaft muckers and shaft drilling jumbos instead of cactus grabs for many projects, which allows the company to do inline work as opposed to concurrent work with people working at the bottom.

“UMS has not thrown the baby out with the bath water in terms of cactus grabs. Where they are used, however, no persons are allowed on shaft bottom during the mucking cycle. This ensures the safety of our workers at all times and eliminates the possibility of an accident during this hazardous phase of the sinking cycle,” says Glover.

International Applications

Glover explains how using vertical shaft muckers will significantly improve operational safety at UMS’s flagship project in Botswana, as a single operator control allows for a pared-down team at the shaft bottom during mucking.

UMS’s scope for the diamond mine in Botswana is a twin-shaft system to a depth of just over 750 m, including the initial studies, design, procurement and construction. The pre-sink has been completed and UMS is currently conducting changeover for the main sink. The project was initiated to extend the life-of-mine after the closure of the openpit.

UMS has also introduced remote-control equipment for the project to further increase the safety of workers and make conditions more ergonomic and comfortable for operators.

Further, in the US state of New Mexico, UMS is undertaking another shaft sinking project and has started to ramp up to full sink by May this year.

“The headgear is erected, and the winders are currently being commissioned. This will be a single ventilation shaft reaching a depth of almost 700 m that will be partially concrete lined, partially thin skin lined and partially unlined,” says Glover.

He says that safety is a massive focus for this project and the shaft will be sunk using muckers, thus reducing the number of people in the shaft when compared with conventional sinking.

He further explains that there will be no concurrent activity with people working above each other.

“Blow over will be done by mechanised means, and there will be limited hand-held drilling. The workforce for this project is highly skilled and multitasked,” says Glover.

UMS will be using a twin-boomed shaft drilling jumbo, which is designed to be fully remote controlled.

The drill is electrohydraulic to reduce harmful noise and increase drilling rates. It can rotate 90º to drill sidewall support, removing hand-held jackhammer drills and reducing injury risk.

Mucking will be done by means of two sidewall-mounted clamshell loaders and the kibbles will be loaded without disconnecting them from the ropes. This means that no workforce is required at the shaft bottom during the most hazardous part of the operation.

The stage will be suspended off four ropes and an emergency escape hoist will be installed.

Further, UMS will use remote-controlled equipment for an underground deepening project in Brazil.

UMS’s scope has been the trade-off and feasibility study and the company is conducting detailed design, project planning as well as early procurement of long-lead items.

UMS expects to begin presinking the 1 500-m-deep shaft later this year as the copper mine transitions from opencast to underground.

Glover says

a further innovation is the replacement of compressed air with hydraulics to reduce the potential for hearing loss and fatigue, which he expects will soon be completely eliminated.

“We will continue to engage with our clients at concept or feasibility phase and assist in developing underground mining projects through to the construction phase in the safest and most productive way,” concludes Glover.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation