Refraline expands local capability with new anchor manufacturing facility

South African refractory specialist Refraline has broadened its manufacturing capabilities with the launch of a new stainless steel anchor production facility, a move the company says will enhance quality control, reduce lead times, and provide customers with a more comprehensive service offering.

Refraline, which has operated in the refractory sector for 45 years, has steadily grown its portfolio across material supply, manufacturing and installation. Refraline divisional manager for material trading, precast and stainless steel anchors Gareth Newall says that the addition of anchor manufacturing represents a natural extension of the company’s existing expertise.

“Refractory anchors tie hand-in-hand with the monolithic products we already produce. Bringing this process in-house strengthens our competitive advantage and allows us to serve customers faster and more effectively,” he notes.

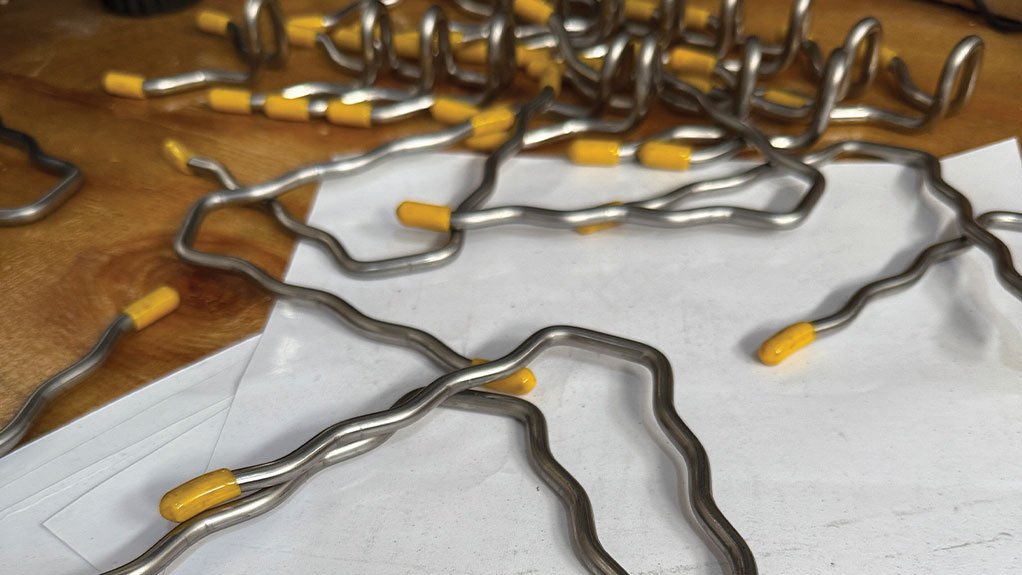

Anchors play a critical role in stabilising refractory linings within industrial furnaces and other high-temperature process equipment. They must be carefully selected and designed based on operating conditions such as heat, vibration and chemical exposure.

“Anchors need to be welded or bolted into place and designed according to the thickness of the lining, the operational environment, and the grade of stainless steel required,” Newall explains. “These factors determine not just the anchor’s dimensions, but also whether materials such as Inconel or higher-grade steels are necessary for extreme conditions.”

Quality Assurance

Quality has been a central focus in establishing the new facility. Refraline sources stainless steel coils from certified suppliers, accompanied by test certificates. These are further verified through in-house and, when required, independent laboratory testing.

“Once we receive the coils, we test them to ensure they meet client requirements. We then label and allocate them by grade, ensuring complete traceability from procurement through to final installation,” Newall explains.

During production, each anchor is checked against design specifications. “We monitor angle, height and diameter closely, ensuring the finished product matches the approved client drawing. That attention to detail underpins the reliability of our anchors in service,” he adds.

By manufacturing anchors locally, Refraline can significantly shorten turnaround times compared with imports. The company also maintains minimum stock levels of commonly used grades to meet urgent requirements.

“The immediate benefit is lead time. Overseas procurement introduces delays, but by producing locally, we can deliver quickly — even on unplanned orders. This strengthens client confidence and secures market share,” Newall says.

Equally important is Refraline’s ability to integrate anchor manufacturing with its wider refractory solutions. “We can manage the full chain, from thermal calculations and design drawings through to material supply, anchor production and final installation. That makes us a true one-stop shop,” he emphasises.

Advanced Technology in Design, Production

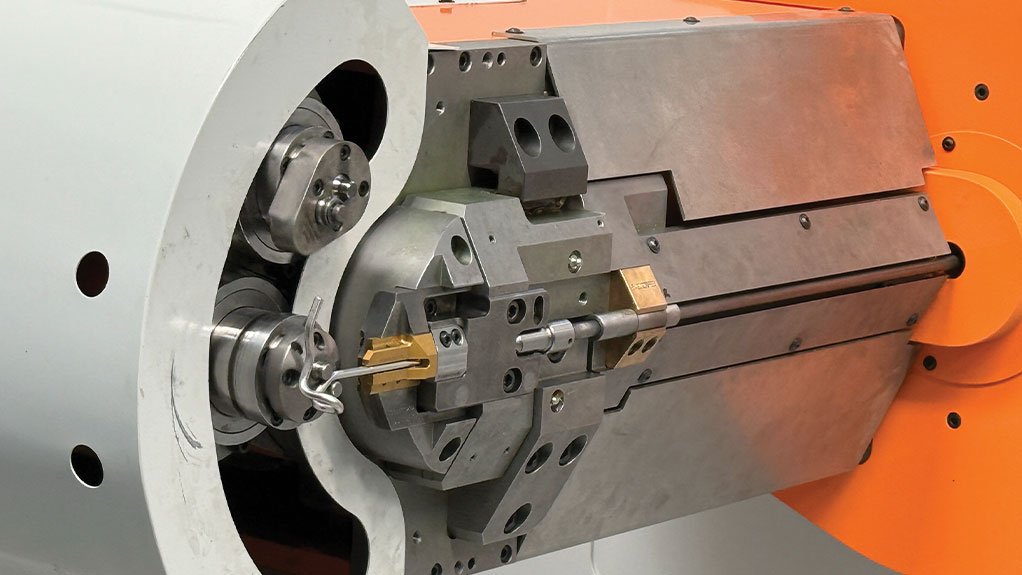

The facility is equipped with a modern 3D computer numerical control (CNC) bending machine, which enables rapid and precise anchor manufacture. Refraline draughtsperson Praylene Dikshoorn explains that the process begins with a CAD drawing, which is converted into a CNC programme.

“Once the client approves a design, I feed it directly into the machine, make the necessary adjustments, and run a sample. If everything matches the drawing, we proceed to full production,” she explains.

Depending on the size, anchors can be produced in seconds. Shorter designs take as little as two seconds, while longer models may require around 12 seconds.

The machine’s bending technology also produces smoother surfaces compared with pressed anchors, which can leave sharp edges. “Pressed anchors often show press marks that may compromise the lining material. With our method, we avoid that risk, ensuring a cleaner, higher-quality product,” Dikshoorn notes.

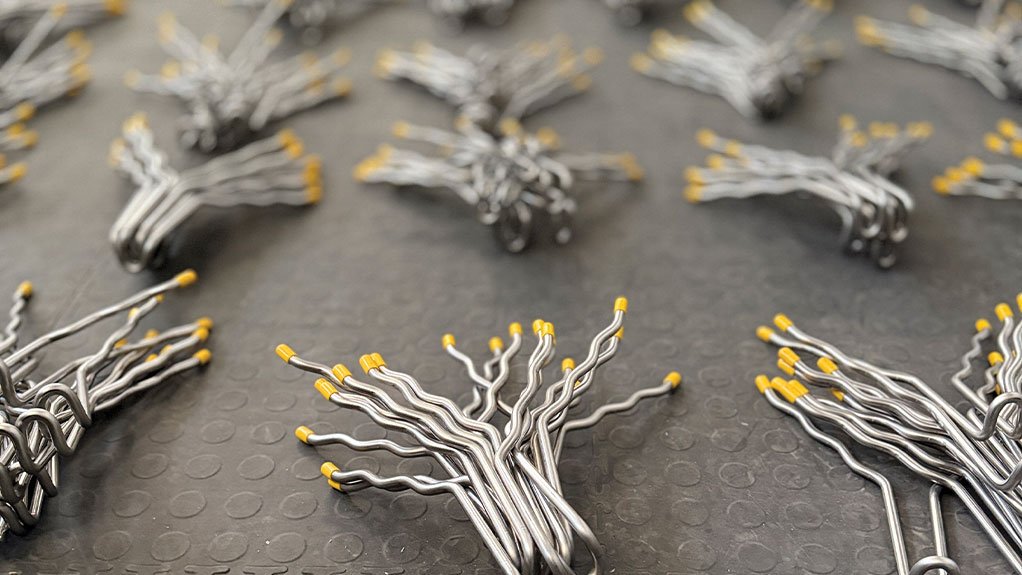

Refraline offers a wide variety of anchor types, from gullwings and bullhorns for shorter linings to more specialised designs for insulated systems. Some anchors are threaded or notched, providing versatility for different installation methods.

“The design depends entirely on the application — whether it’s for insulation, wear resistance or impact resistance. We work closely with clients to advise on the most suitable solution,” Dikshoorn says.

Looking ahead, Newall sees the anchor facility as a springboard for further expansion. “Right now, one CNC machine can handle a substantial workload. But as demand grows, we anticipate adding more machines and broadening our capacity,” he says.

For Refraline, the new division represents more than just additional capability. It reinforces the company’s reputation for professionalism, quality and innovation in refractory solutions.

“What we want clients to see when they walk into this facility is neatness, cleanliness and professionalism; a reflection of the standards Refraline has maintained for 45 years,” Newall concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation