Research team develops plans to use old mines as power generating plants

An international team of researchers have developed a method to store kinetic energy, which can later be converted to electrical energy, using decommissioned underground mines.

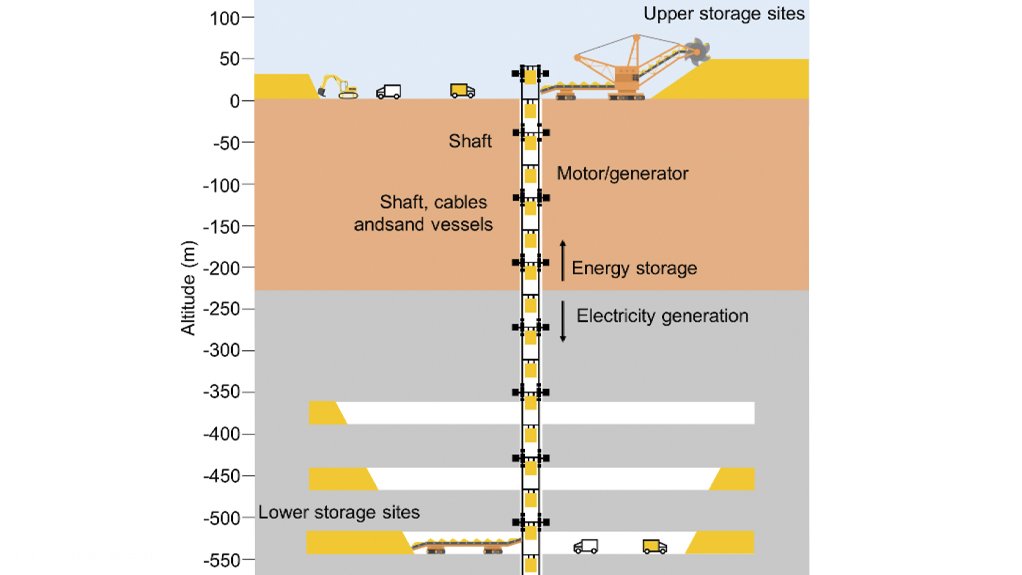

The Underground Gravity Energy Storage (UGES) concept, developed through a study led by the International Institute for Applied Systems Analysis (IIASA), works by using the weight of sand and letting it fall down a mineshaft through regenerative braking systems that power dynamos, which produce electricity.

Once the system has been used, it can be lifted back up the mine shaft to an upper reservoir using electric motors to again store energy.

The main components of UGES are the shaft, motor or generator, upper and lower storage sites and mining equipment.

The deeper and broader the mine shaft, the more power can be extracted from the plant, and the larger the mine, the higher the plant's energy storage capacity, the IIASA team states.

The team also points out that renewable energy sources are central to a greener and sustainable energy transition but that sun and wind resources are variable by nature. This means a system that can supply power consistently at specific points may be required to bridge deficit points in time.

The UGES concept can generate electricity when the price is high.

Lead study author, IIASA energy, climate and environment programme researcher Julian Hunt says that when a mine closes, it lays off thousands of workers, negatively impacting communities that rely on such mines for an income.

“UGES would create a few vacancies as the mine would provide energy storage services after it stops operations.

“Mines already have the basic infrastructure and are connected to the power grid, which significantly reduces the cost and facilitates the implementation of UGES plants,” he adds.

Further, the research team points out that other energy storage methods, such as batteries, lose energy through a process known as self-discharge, over long periods. However, they point out that because UGES uses sand, no energy is lost to self-discharge, enabling ultra-long time energy storage ranging from weeks to several years.

The research team posits that investment costs of commissioning a typical UGES system range between $1/kWh to $10/kWh, and power capacity costs of $2/kW.

The technology is estimated to have a global potential of between 7 TWh and 70 TWh, with most of this potential concentrated in China, India, Russia and the US.

Study co-author, IIASA energy, climate and environment programme researcher Behnam Zakeri says that, to decarbonise the economy, innovative energy systems using existing infrastructure need to be developed.

“Turning abandoned mines into energy storage is one example of many solutions that exist around us, and we only need to change the way we deploy them,” he says.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation