SANS 1589 Failsafe Emergency Brakes

Since the early 2010s, industrial equipment manufacturer and supplier AIM Equipment (B-BBEE Level 2) has devoted several resources into the design and development of true SANS 1589-certified brake systems through its in-house design office. The driving force was to create safer machines and, in essence, a safer working environment. This goes hand-in-hand with proximity detection systems (PDS) / collision avoidance systems (CAS) entering the South African mining sector. Upon completion of the first system, which was tested and approved by Gerotek, AIM registered patents for independent failsafe brake systems, controllers and designs.

Historically, diesel trackless mining machinery (TMM) was very basic equipment, and in some cases, it was agricultural tractors that were converted into machines that conformed to the mining requirements of that time. On some aspects, the industry had to settle for the available technology of that time.

AIM has been at the forefront of the continued development of mining machinery, which resulted in the FL-AIM-TRAX tractor series. These machines are setting the standard and introduce new technology to the South African mining sector.

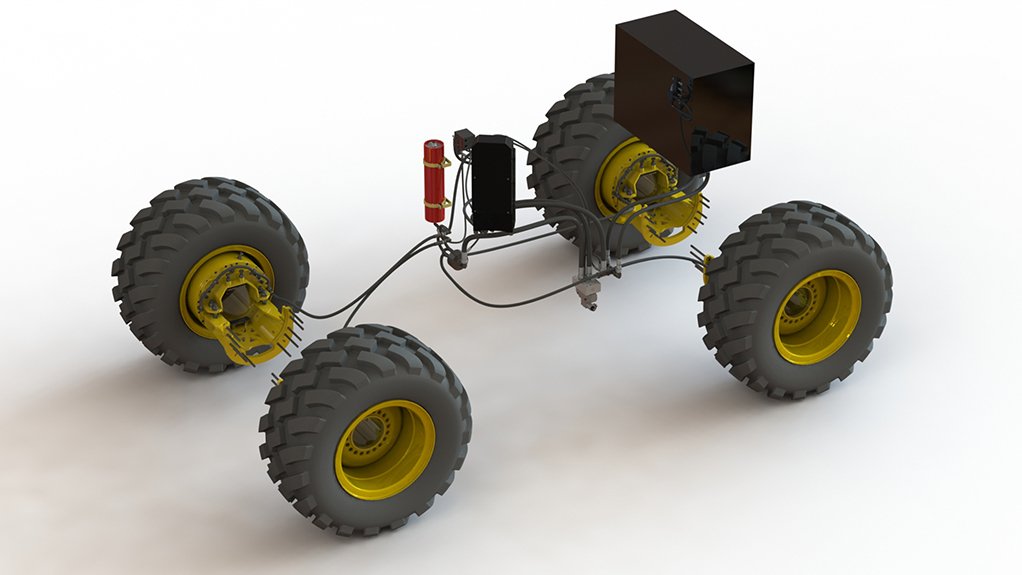

Part of our development is the AIM failsafe emergency brake systems which fully conform to all the requirements stipulated by SANS 1589 and more.

The brake units are custom designed for each application, and are durable so as to provide extremely long service by using world class componentry. The majority of components are manufactured locally to ensure availability. These units are also designed to avoid machine component modifications. The advantage of such a design method is that original equipment manufacturer (OEM) parts are replaceable with standard OEM parts.

In 2013, AIM became the first OEM to successfully implement full Level 9 PDS interfacing on its diesel TMMs. Level 9 PDS means that the machine is able to automatically reduce speed and / or engage emergency brakes without any input from the operator when the PDS / CAS system is triggered.

AIM began receiving enquiries from mining companies and equipment OEMs to design emergency brake systems which can be fitted onto their equipment to enable them to be used on sites where such systems are mandatory.

The utilisation of PDS will become mandatory in the next few years and, when done correctly, can save lives.

Our latest certified installation was done on a 30 t CAT 950 loader.

Today, our brake systems are much more than just a disk and calliper. Our systems use state-of-the-art components of the highest quality.

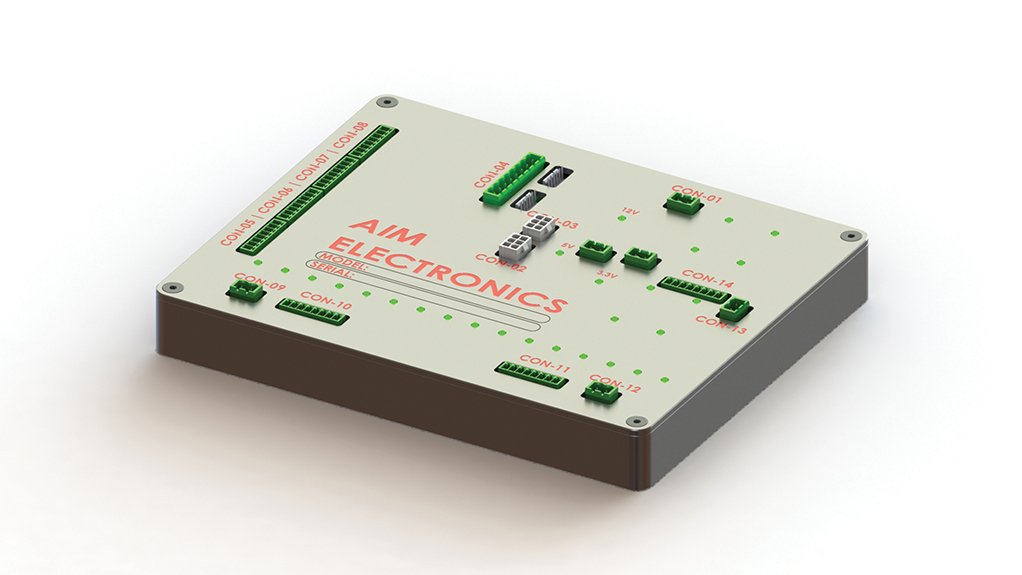

It is computerised and programmable to suit each application and each end-

user’s needs. Among others, it includes feature functionalities such as neutral braking, disabling drivetrain power output while brakes are engaged, inclination monitoring, transmission control, engine control, operator demand interception and manipulation, door interlock, seatbelt interlock, machine speed monitoring, payload sensing, PDS / CAS interfacing, Bluetooth communication, data logging etc.

Taking all of the above into consideration, we are able to restrict the machine from operating dangerously. For example, limiting the machine’s ground speed to the extent that if an emergency stop is initiated, it can be executed safely, based on the load it is carrying, and the machine’s inclination. Because of this, autonomous vehicles can also benefit greatly by making use of our brake system by drastically reducing the possibilities for vehicle-to-vehicle and vehicle-to-pedestrian collisions.

Our products are used across South Africa, from the south-west regions just north of Cape Town to the north-eastern part of the country at diamond mines, with the main cluster being Mpumalanga’s coal mines. Some of our customers include Exxaro, Seriti, Jindal, De Beers, Anglo American and Goldfields.

In conclusion, AIM provides the complete solution from concept design, through prototype manufacturing, production, installation, documentation and maintenance, producing customised brake systems of the highest standards to a wide variety of sectors and giving resellers and end-users peace of mind knowing that they have partnered with the best.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation