SEW-EURODRIVE awarded largest African projects, partnerships grow

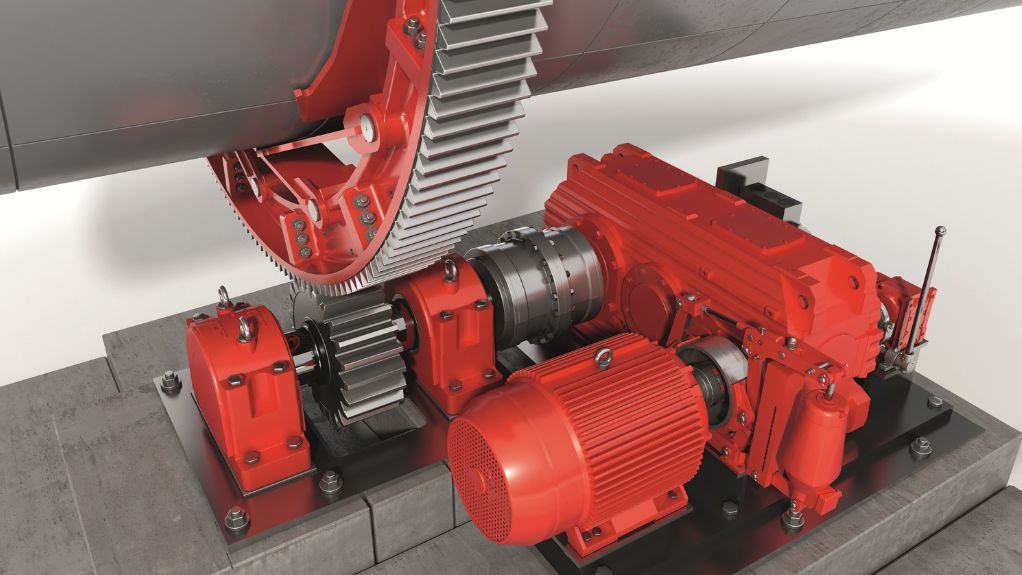

GIRTH GEAR A segmented girth gear working in tandem with an industrial gear unit to drive high-performance, large-diameter rotating equipment

REVERSE ENGINEERING Advanced reverse engineering capabilities allow SEW-EURODRIVE to support industrial gear units from any manufacturer, ensuring reliable refurbishment and optimisation

As the spotlight falls on Africa’s mining progress at this year’s Investing in African Mining Indaba, global drive technology specialist SEW-EURODRIVE reports a milestone performance for the past year – being awarded some of its largest projects yet in the copper, chrome, coal, platinum and gold sectors.

“It has been a phenomenal year for us as a South Africa-based entity operating in 23 African countries,” says SEW-EURODRIVE national sales and marketing manager Jonathan McKey.

He adds that the company has had great success in Africa’s mining sector, building on the market’s confidence in SEW-EURODRIVE’s quality solutions and customer support.

This success, says McKey, reflects almost three decades of technical investment, relationship-building and a deep understanding of African mining conditions.

With its partnership-driven approach to the mining value chain, SEW-EURODRIVE works closely with original-equipment manufacturers; engineering, procurement and construction management (EPCM) contractors and mining companies, from feasibility through to commissioning and beyond.

This ensures that its drive systems are sized correctly, aligned with mine layouts and specified to meet life-of-mine requirements.

The company is also expanding its planetary gearbox offering and reinforcing its presence in open gearing girth gear solutions, which are areas critical to mill performance.

“We have closed the loop on our end-user relationships and brought extensive value back to our work with the project houses.

“Through our detailed understanding of end-user requirements, as well as the dynamics of their facilities and production needs, we now have the inventory and insights to add further value to our relationships with EPCM players,” says McKey.

This, he argues, has positioned SEW-EURODRIVE as a partner of choice in both greenfield and brownfield projects – from new conveyor installations to plant expansions, drop-in replacement solutions and modernisation programmes.

McKey highlights that energy efficiency and reduced downtime remain central priorities for African mines, and SEW-EURODRIVE’s drive technology is engineered to support both goals.

“There has been a strong shift towards mines being more energy efficient, in Africa and globally,” he says, adding that SEW-EURODRIVE continues to evolve its drives and technology to ensure clients consume less power without compromising reliability or output.

“Our on-site energy surveys for mines have become an important platform for partnerships that drive improvements across whole operations.”

Predictive maintenance has also become a focus for mines to optimise uptime by preventing unplanned equipment stoppages.

He says SEW-EURODRIVE is supporting mining operations through digital tools such as its DriveRadar predictive maintenance suite, which in conjunction with the DriveRadar diagnostic unit, monitors gearbox, motor and drive health in real time.

“DriveRadar monitors vital indicators such as vibration, oil viscosity and temperatures – gathering and analysing the data to enhance how mines monitor their equipment and identify any performance anomalies,” he says. This allows customers more flexibility in managing their products’ reliability and ensuring more uptime.

Training remains a strategic pillar in SEW-EURODRIVE’s partnership with mining customers, he says, with the company’s Drive Academy providing a dedicated and professional resource to train artisans, engineers and plant personnel to better understand and maintain their equipment.

“The Drive Academy also strengthens our in-house expertise at various levels; when we employ new personnel, for instance, their induction process includes extensive training sessions in the academy,” says McKey.

As part of this training, he says salespeople even go into the workshop and physically assemble gearboxes so they understand every element of the product.

A cornerstone of SEW-EURODRIVE’s value proposition is its significant investment in South African manufacturing and service infrastructure. In recent years, the company has expanded its production and warehousing facility at its headquarters in Johannesburg, considerably increasing its local stockholding to underpin its capacity and responsiveness.

“The value of our stockholding has grown from around R100-million to well over R500-million,” says McKey, adding that this includes all aspects of SEW-EURODRIVE’s offerings to mining in Africa.

“By understanding customer requirements and investing in our solutions, we have stocked accordingly to improve our agility, delivery time and aftermarket support.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation