Sorting technology exceeds client expectations

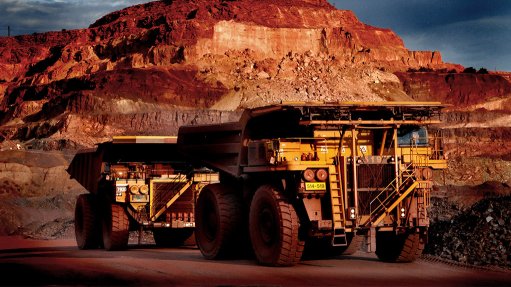

NEW TECH By implementing new sorting technologies, Queensland Magnesia’s Kunwarara openpit operation in Australia continues to show positive results

SORTING SORTED The new Tomra XRT sorter has improved output at the Queensland Magnesia’s Kunwarara openpit operation

An X-ray transmission (XRT) sorter employed at magnesia products producer Queensland Magnesia’s (QMAG’s) Kunwarara openpit operation in Australia since 2016 has shown positive results, exceeding expectations in terms of its sorting capabilities.

QMAG mines ore using an openpit method and processes it into high-quality fused, dead burnt and caustic calcined magnesia products at the nearby Parkhurst facility, in Queensland.

The miner supplies the refractory, chemical, agricultural, environmental and hydrometallurgical sectors with its high-quality magnesia products and was an early adopter of sensor-based ore sorting technology – claiming to be one of the longest continuous users of this technology in Australia – having installed its first Ultrasort laser machine in 1994 and a second one a few years later.

The ore was fed through a dense media separation (DMS) system, using drum and cyclone separators, following which the Ultrasort sorters removed the sandstone, gravel and dark coloured dolomite from the product.

However, after more than 22 years in operation, the Ultrasort sorters became antiquated and could no longer be supported.

“It came to a point where the Ultrasort sorter was removing the dolomite, but the background lime was still quite high, and this was not giving us the best opportunity to create the product that was required by the Parkhurst processing plant,” explains QMAG mine production superintendent Josh Dawson.

Proceeding from this point, a new solution was needed, and collection and sorting systems developer Tomra suggested its XRT technology.

In 2016, a Tomra XRT sorter was installed as a standalone plant on site.

Dawson explains that it was a trial that management at the time got excited about because they could see that this could be the future, moving forward.

“It was a success story. We could now process very high calcium content material that we could not do as effectively with the DMS or laser sorting equipment. This gave the ability to produce much lower calcium content magnesite grades suitable for our customers,” adds QMAG mine process engineer Alex Padya.

Following these results, the XRT machine was moved into the sorting plant in 2018 where it replaced the remaining Ultrasort that had reached the end of its life, and the DMS drum was decommissioned.

“With this decision, we halved our heavy media usage in that part of the circuit and went to a standalone XRT circuit,” says Dawson.

As a result, the XRT circuit has delivered significant savings in energy and water use, and increased the plant’s efficiency, thereby exceeding QMAG’s expectations.

The results were so positive that QMAG updated its plant, replacing the six-year-old unit with a new Tomra XRT sorter.

In addition, a second Tomra XRT unit has now been added to further increase production capacity through this process route.

QMAG is currently considering the possibilities that ore sorting technology can open up for the future.

“When we originally made the business case, we thought that it would be used to upgrade the lower quality magnesite ores to produce grades suitable for agricultural purposes, while the heavy media cyclones would make our lower silica materials for other applications,” he says.

However, Dawson notes that by collaborating with Tomra to enhance the performance of the XRT unit, QMAG can now turn agricultural products into much higher grades required by the Parkhurst processing plant.

“We see that the technology is improving to the point where we’re starting to consider that XRT can potentially do what the heavy media can do, and in some respects better,” says Dawson.

“Over the last few years we have done a lot of runs without going through the cyclone, going straight to the XRT sorter, and ending up with the final product,” says Padya.

Added Benefits

Tomra’s XRT sorter has also extended the life of QMAG’s deposit, whereby it proved that the miner could produce lower end products from its currently mined orebody.

Padya also points out that the Tomra XRT is “very easy” to operate.

“We have three specific sorting programmes, depending on the feed material, to get a very intensive, mild or slight rejection rate. Once set up, you virtually leave the Tomra XRT sorter to do its job,” states Padya.

Dawson adds that having programmes preset in the machine, instead of using the slidescale, alleviates human error and makes the process seamless.

According to Tomra, switching programmes on the XRT is simple and quick, which makes the machine agile in responding to the frequent variations in the material that comes from the orebody at QMAG’s deposit.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation