South Africa’s Phalaborwa rare earths project is gift that just keeps on giving

Now scarce yttrium emerging.

Phalaborwa rare earths project.

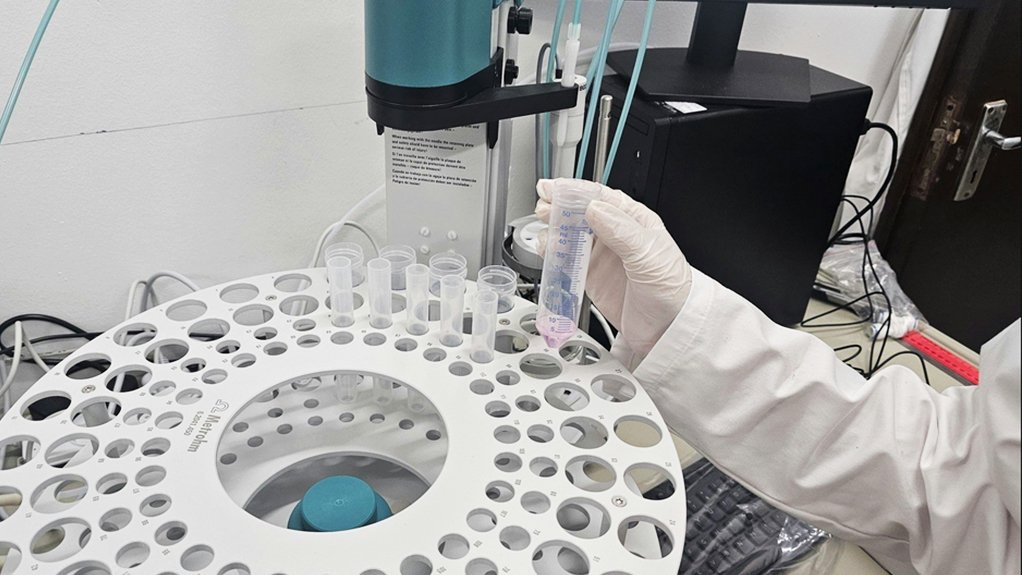

Smart test work.

Rare earths project site.

Successful downstream work.

JOHANNESBURG (miningweekly.com) – South Africa’s rare earths endowment at Phalaborwa in Limpopo province is a gift that just keep on giving through the ongoing effort of Rainbow Rare Earths.

In December, Mining Weekly reported that 150 000 t of rare earths would be produced from gypsum stacks at Phalaborwa at an operating expenditure believed to be the lowest of any project in the West and probably even below that of projects in the East.

In September, an exceptionally pure rare earths product from Phalaborwa was optimised in the Johannesburg laboratory of Rainbow Rare Earths.

In October, more smart testwork in the company’s Johannesburg laboratory enabled another forward leap for rare earth elements (REEs).

Now, scarce yttrium has been added to the list of heavy rare earths coming out of Phalaborwa, which already includes neodymium, praseodymium, dysprosium and terbium in the project’s basket.

Phalaborwa is turning out to be a very distinctive project in that it hosts commercial quantities of the full gamut of economically important rare earths, including the medium and heavy REEs.

“We’ll therefore look to incorporate the value of the full range of strategic REEs into our economic model for the project as part of the definitive feasibility study,” Rainbow Rare Earths CEO George Bennett has pointed out.

Rainbow’s Phalaborwa project is now confirmed as a strategic and near-term source of all the economically important medium and heavy REE, being dysprosium, terbium, samarium, europium, gadolinium and yttrium, as well as the critical light REEs, being neodymium and praseodymium and these REEs have been confirmed as critical minerals by a list released on November 6.

The South Africa-based and London-listed Rainbow Rare Earths aims to be a forerunner in the establishment of an independent and ethical supply chain of the REEs that are driving the green energy transition.

It is doing this successfully via pioneering the first commercial recovery of REEs from phosphogypsum that occurs as the by-product of phosphoric acid production.

This project eliminates the cost and risk of typical rare earth projects, which involve mining and the production of a rare earth concentrate that must be chemically cracked to form a mixed rare earth carbonate before further downstream processing.

As such, Rainbow Rare Earth’s projects can be brought into production quicker and at a lower cost than traditional hard rock mining projects.

Rainbow’s process will deliver separated rare earth oxides through a single hydrometallurgical plant on site, with a focus on the recovery of neodymium, praseodymium, dysprosium and terbium – critical components of the high-performance permanent magnets used in electric vehicles (EVs), wind turbines, defence and new markets such as robotics and advanced air mobility.

The Phalaborwa updated interim economic study released in December 2024 has confirmed strong baseline economics for the project, which has a base case net present value of $611-million.

Phalaborwa is being increasingly recognised as one of the highest margin rare earth projects in development.

These projects eliminate the cost and risk of mining, meaning that they can be brought into production quicker and at a lower cost than traditional hard rock mining projects.

The 35-million-tonne resource provides a 16-year life-of-project, amid low operating expenditure and relatively high grade, making the project a hardy frontrunner.

The availability of phosphogypsum is the result of the mining of a hard-rock phosphate deposit, which has been carried out by South Africa’s Foskor for the last 60 years.

The mined material is concentrated through a flotation process into a phosphate slurry, which over the period has been the feed for a nearby phosphoric acid plant, where two key ingredients were added, namely sulphuric acid and heat to create phosphoric acid.

The rare earths in the phosphate slurry were further upgraded in the phosphoric acid sludge in the phosphoric acid plant and then that phosphoric acid production created a gypsum waste residue that was transported in a concentrated form to the gypsum stacks. South African State-owned research organisation Mintek has been part of successfully enabling commercial extraction from the phosphogypsum.

The project is going to clean up an old opencast mine, a dormant Sasol phosphoric acid plant, and two unlined environmentally hazardous gypsum stacks. The ready-fenced and power-lined site comes with the advantage of having a high-voltage switchyard.

Hankering for REEs are wind turbines, EVs, robotics, advanced air mobility, smartphones, laptops, medical imaging equipment and more.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation