Summary of Research Report: Effects of Retrofit Diesel Particulate Filters (DPFs) on Diesel Particulate Emissions

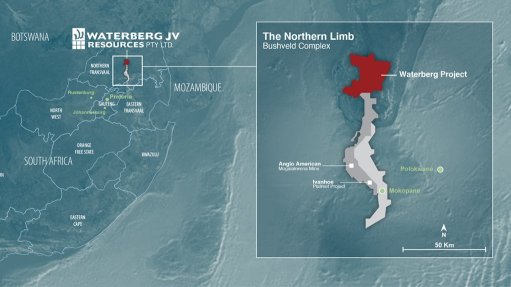

The research explored the effectiveness of retrofitting Diesel Particulate Filters (DPFs) to diesel-powered machinery in an underground platinum mine in Limpopo, South Africa. Diesel Particulate Matter (DPM) from diesel engines poses a significant health risk, particularly in confined spaces such as underground mines. This study aimed to determine how well DPFs reduce these harmful emissions.

Key Findings of the report:

1. Significant Emission Reduction: The DPF systems reduced particulate mass emissions by an average of 84% and particle number concentration by 97%. This shows that DPFs are highly effective in filtering harmful particles from diesel exhaust.

2. Health Benefits: The study showed a significant decrease in workers' exposure to Elemental Carbon (EC), which is a key component of DPM. Before retrofitting, personal exposure levels were much higher, with some reaching 338 µg/m3, but post-retrofitting, exposure dropped to 16.7 µg/m3, highlighting the positive impact on worker health.

3. Stable Performance Over Time: The DPFs maintained consistent performance even 256 days after installation, showing that they provide long-term benefits in reducing emissions without significant deterioration.

4. Effective Regeneration: The study highlighted that DPFs performed better during hot engine operation, effectively regenerating and clearing trapped soot. However, regeneration efficiency dropped slightly when the engine was cold.

Conclusion of study

Retrofitting DPFs on diesel-powered machinery significantly reduces harmful diesel emissions and protects workers' health in high-risk environments like underground mining. The use of these filters is a critical intervention to improve air quality and safety standards in industries that rely heavily on diesel-powered equipment.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation