Upgraded mobile screen launched onto Southern African market

Wirtgen South Africa mineral technologies sales executive Mike Newby details the Kleeman Mobiscreen 953 EVO. Camerawork and Editing: Nicholas Boyd.

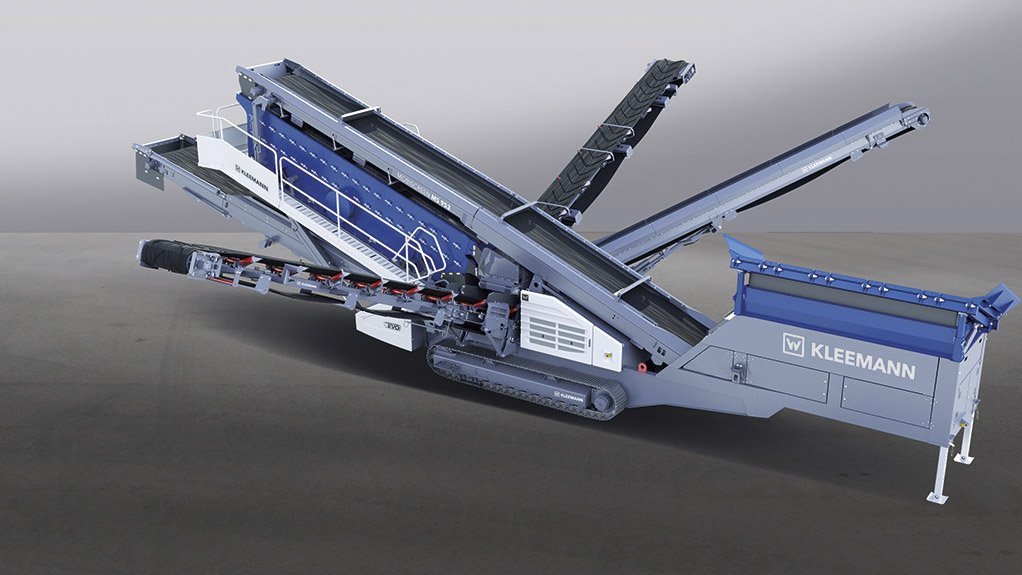

SCALED-UP SCREEN The MS 953 EVO improves safety, increases efficiency and enhances ease of transport, maintenance and operations

SUCCESSFUL EXECUTION Wirtgen has already sold one MS 953 EVO screen in Southern Africa

Mining solutions provider Wirtgen South Africa officially launched its new Kleeman Mobiscreen MS 953 EVO at its head office in Kempton Park, Johannesburg, on September 15.

Wirtgen has already sold one of its new screens on September 14, taking the number of EVO line screens present in the Southern Africa mining industry to two, with the company having sold the preceding MS 703 EVO screen to a client following its launch in June.

Wirtgen South Africa MD Heinrich Schulenburg extols that, despite tough times for the local economy, owing to factors such as policy uncertainty – to which Wirtgen has not been immune – the company has been able to launch a new machine. This development, he says, is commendable, as it enhances the state of the mining industry.

The MS 953 EVO, part of Kleeman’s Evolution range, is a triple-deck mobile screening solution, with the upper deck having a 9.5 m2 superscipt screening area.

Wirtgen South Africa mineral technologies sales executive Mike Newby says the new Kleeman mobiscreen was manufactured at Wirtgen Group’s facilities, in Germany, about 12 months ago and was officially introduced to the world at the Steinexpo, an industry trade fair held from August 30 to September 2.

The screening brand from tracked crushing and screening plant manufacturer Kleeman is just one of numerous other road building and mineral processing brands supplied by Wirtgen South Africa, with Kleeman becoming a part of Wirtgen Group in 2016.

Schulenburg tells Mining Weekly that Kleeman’s MS 953 EVO is an upgrade of its MS 19 D, and a slightly bigger model at 3.2 m × 18.6 m × 3.4 m in transport mode and weighing 36.3 t.

Owing to its new features and improvements, Schulenburg believes that the new mobiscreen is even more applicable to the mining industry than its predecessor.

Newby notes that the new EVO range of mobile screens is focused specifically on improving safety, increasing efficiency and enhancing ease of transport, maintenance and operations.

“Safety is always a big concern for us on site, especially at quarries and mines, while efficiency or fuel economy is obviously top of mind for our clients, with ease of transport, operation and maintenance also being very important.”

The most significant feature from a safety point of view is that, unlike other screen brands, the MS 953 EVO does not require operators to stand directly next to the machine to unfold and fold the conveyers by manually pulling levers installed on the side of the machine. Rather, the new screen has three access points where a remote controller can be plugged in and used to unfold or fold the conveyors from a distance. Operators are, therefore, not exposed to the unfolding or folding process, or the dangers posed by moving conveyors.

The remote control can also be used to drive the screen around a mining site and to stop and start the screening process.

The second notable safety feature that Newby highlights is a nonreturn valve system for the hydraulic cylinders on the conveyers. He explains that a valve on each cylinder will prevent the cylinder arm from retracting if the hydraulic system malfunctions and, subsequently, loses pressure. In contrast, on other machines, a hydraulic failure could easily lead to a conveyer lowering and injuring someone on site.

In terms of safety and ease of maintenance, Newby notes that the screening box is surrounded by platforms to allow for easy access for maintenance and screen changes. The screen change process is facilitated by the use of easily removable wedges. Once the screen has been replaced, the wedges are returned to their storage point and secured.

Owing to its compact size, the screen is easy to transport to site and also requires no special permits to be transported.

Enhancing efficiency, the mobiscreen is equipped with an optional water-spraying system, which is used for mining applications where clay or wet and sticky material is a challenge. The spraying system is placed on top of the screening belts to wash away unwanted material, thereby improving screening efficiency.

The fuel consumption of the MS 953 EVO is between 12 ℓ/h and 13 ℓ/h. However, Newby says its dual-power option enables mining operations to bypass the screen’s on-board power unit and switch to an alternative power source, thus, reducing the fuel costs of running the mobiscreen.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation