Valves maintenance still a challenge

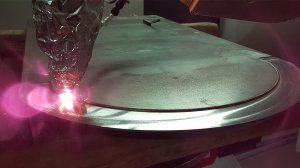

IRREPLACEABLE SOLUTIONS The initial coating of new valves as well as their efficient repair results in fewer valve replacements

Although demand for valves has increased over the past five years, maintenance costs, efficiency and valve service life are some of the challenges that companies face yearly, says coating technology specialist Thermaspray’s laser cladding manager Jordaan Lourens.

“Thermaspray addresses the aforementioned challenges through innovative surface engineering solutions that can restore a worn valve to original-equipment manufacturer specifications.”

The company can also extend the service life of the valve by applying materials that increase wear resistance and efficiency, which, in turn, reduce maintenance costs over time, he adds.

Thermaspray’s spray shop manager Paul Young tells Engineering News that as the valves sector is critical to many industries in these trying financial times, simply replacing a valve is not always the best option, owing to price and delivery.

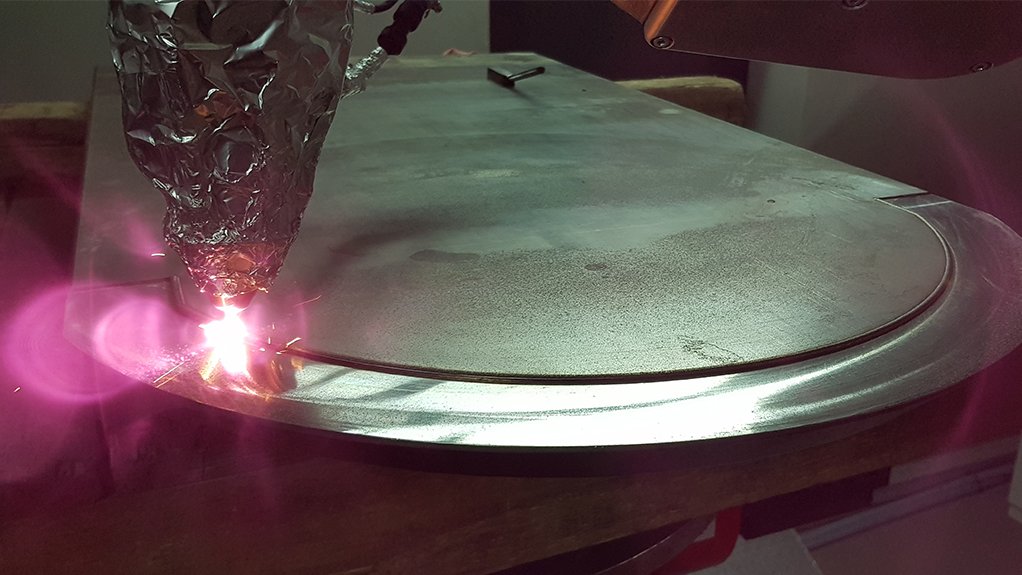

Hence, the company’s refurbishing of many types of valves using thermal spray coatings, plasma-transferred arc welding and laser cladding is crucial.

“It is also possible to treat a new valve’s working components with a coating and/or cladding suited to the specific environment the valve operates in, to extend its life. This could be for abrasion, erosion or corrosion, for example,” he highlights.

Notably, the initial coating of new valves as well as their efficient repair results in fewer valve replacements. Therefore,Thermaspray engineering support manager Phillip van Wyk advances that making use of modern, specially developed materials applied on the substrate materials to increase the wear/corrosion resistance of the valves consequently results in the life of a valve being extended.

“A large amount of the work that we do involves power stations and mines, where we conduct complete refurbishments. This includes the application of special materials to worn-out valves as well as stripping, inspection and the removal of damaged/old coatings, besides others,” he points out.

Notably, the Covid-19 pandemic has made maintenance and repair of pumps and valves particularly difficult, says Thermaspray MD Dr Jan Lourens.

As such, delayed repairs and/or maintenance, has increased. This, he stresses, has resulted in plant uptime decreasing and general plant output being impacted on negatively.

“With special dispensations being made for the maintenance of equipment, this will, hopefully, get back to normal soon.”

Consequently, Thermaspray and joint venture company Surcotec are trying to move closer to their customers to understand their maintenance schedules and requirements better.

This, he concludes, will ensure that the company can readjust its strategies so that the pandemic does not adversely affect its operations on a large scale.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation