Berg gold project, Canada – update

Photo by Surge Copper Corp

Name of the Project

Berg gold project.

Location

Tahtsa Ranges of British Columbia, Canada.

Project Owner/s

Canadian-based mineral exploration and development company Surge Copper Corp.

African Rainbow Minerals (ARM) entered into a subscription agreement for a private placement financing with Surge Copper in April 2024. ARM will subscribe for 39 608 708 common Surge shares for C$3.8-million through its wholly owned subsidiary ARM Copper. ARM will own 15% of Surge’s shares on completion of the placement, subject to TSX Venture Exchange and South African Reserve Bank approval.

Project Description

The project has an estimated 30-year life-of-mine, with average yearly production of 191-million pounds of copper equivalent.

Mine planning is based on large-scale conventional drill, blast, load and haul openpit mining methods suited to the project location and local site requirements.

The process design is based on processing mineralised material from the Berg deposits through copper and molybdenum flotation to produce saleable copper and molybdenum concentrates.

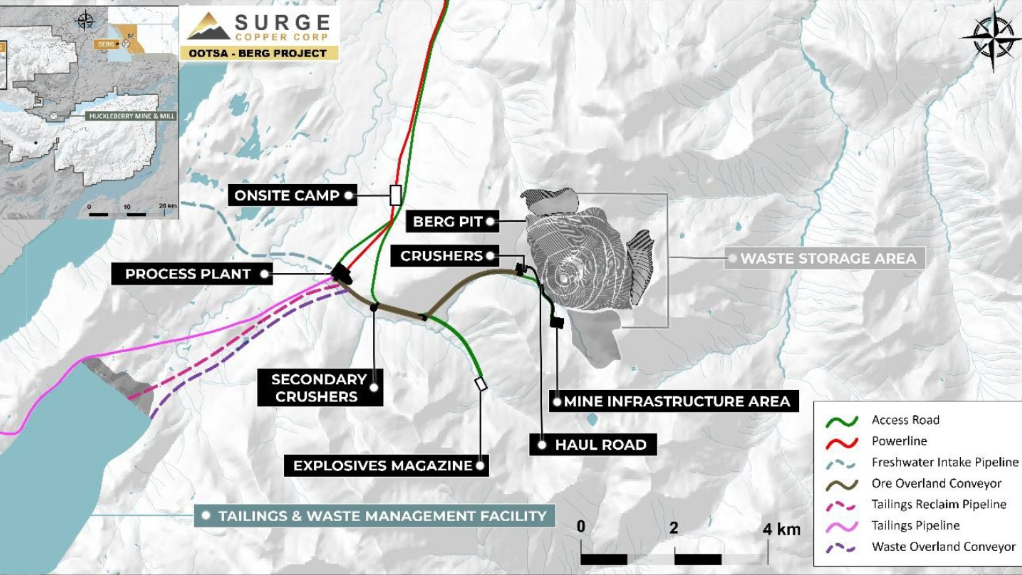

Mine facilities include:

- mining administration offices, a mine fleet, truck shop and mine workshop, as well as wash bays;

- common facilities, including an entrance/exit gatehouse, a security/medical office, an overall site administration building, potable water and fire water distribution systems, compressed air facilities and power distribution facilities, as well as diesel reception and communication areas;

- a near-pit mineralised material and waste crushing facility with associated electrical infrastructure;

- process facilities housed in the process plant, including grinding and classification, flotation, regrinding, concentrate handling, reagent mixing and distribution, as well as an assay laboratory, process plant workshop and warehouse; and

- an on-site camp, tailings and waste management facility, as well as a nonacid-generating rock storage facility.

The processing plant is designed for a throughput of 90 000 t/d at 92% availability. The crushing circuit is designed with an availability of 75%. Average production is estimated at 125.9-million pounds of copper, 13.3-million pounds of molybdenum, three-million ounces of silver and 12 000 oz of gold.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

On an after-tax basis, the net present value, discounted at 8%, is estimated at C$2.08-billion and the internal rate of return at 20%, with a payback period of 3.9 years.

Capital Expenditure

About C$1.97-billion.

Planned Start/End Date

Not stated.

Latest Developments

Surge Copper Corp has completed its 2025 multidisciplinary drilling and field programme, in a key step towards a prefeasibility study (PFS) planned for the first half of 2026.

The programme is aimed at advancing the project towards the completion of a PFS, with work focused on upgrading mineral resources, validating historic drilling data and completing technical and environmental studies needed for mine design and permitting.

In an update on January 8, Surge Copper reported that four infill drill holes completed last year had successfully intersected the outer margins of the Berg deposit. The results are expected to support the conversion of continuous porphyry-style mineralisation currently classified as inferred into higher-confidence indicated and measured resource categories in a future mineral resource update.

Surge Copper also resampled 17 historic core drill holes using modern analytical methods and updated quality assurance and quality control protocols. This has materially increased confidence in the historic dataset and supports its use in future mineral resource estimation and classification.

The resampling work identified a meaningful silver component in the north-western portion of the deposit. Surge Copper said multiple drill holes in this area had returned long intervals with elevated silver grades and that, when combined with the 2025 infill drilling results, copper-equivalent values increased in an area targeted for resource category conversion. The company said this could have a positive impact on future resource estimates.

Additional drilling was also completed to support acid rock drainage assessment and geotechnical modelling. Surge Copper has said the data provides critical environmental and engineering inputs for mine design and permitting and forms part of the technical foundation needed to advance the project to prefeasibility.

CEO Leif Nilsson said the 2025 programme delivered key technical data required to progress the Berg project, including information to support resource upgrades, geotechnical design and environmental geochemistry. He added that the programme had been completed safely and on schedule, and noted that the historic core resampling had revealed a significant precious-metal component, particularly silver, which enhanced copper-equivalent value and highlighted potential upside ahead of the next resource update.

Surge Copper said the work programme positioned the Berg project for a mineral resource update and the planned PFS in the first half of 2026.

Key Contracts, Suppliers and Consultants

ALS Metallurgy Kamloops (metallurgical test programme) and Ausenco Engineering Canada (lead consultant – PFS); and Moose Mountain Technical Services (mineral resource estimation, openpit design and scheduling).

Contact Details for Project Information

Surge Copper, tel +1 604 718 5454 or email info@surgecopper.com.

Article Enquiry

Email Article

Save Article

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation