Cinovec lithium project, Czechia/Germany – update

Name of the Project

Cinovec lithium project.

Location

In the Krusne Hory mountains, which straddle the border between Czechia and the state of Saxony, in Germany.

Project Owner/s

The project is a joint venture (JV) between mineral exploration and development company European Metals Holdings and power distribution company CEZ.

Project Description

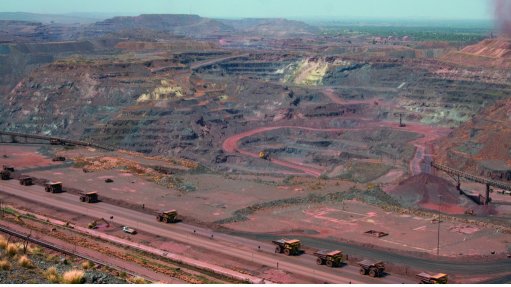

Cinovec is the biggest hard-rock lithium deposit in Europe and the fourth-biggest nonbrine deposit in the world.

The project aims to produce about 29 386 t/y of battery-grade lithium oxide over life-of-mine (LoM).

The mine will be accessible by a twin decline system.

The planned mining method is longhole stoping with backfill using paste backfill. The project ore extraction rate is estimated at 54.5-million tonnes, consequently allowing for a processing rate of 2.25-million tonnes over an LoM exceeding 25 years.

Mining consultancy Bara Consulting has conducted a concept study exploring the feasibility of raising run-of-mine (RoM) output while maintaining the same mine portal area, boxcut and twin decline system initially designed in the prefeasibility study (PFS).

The updated mine plan accelerates production, and introduces inferred resources into the final eight years of mining. Over its 26-year life span, the project is expected to extract 74-million tonnes of ore, a 36% increase compared with the earlier PFS.

The enhanced production figures are part of ongoing work for a definitive feasibility study (DFS), scheduled for completion in mid-2025. The study incorporates optimised mining and processing strategies, leveraging advanced metallurgical testwork that has achieved high lithium recovery rates.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

The project has a net present value, at an 8% discount rate, of $1.94-billion and an internal rate of return of 36.3%, with a payback of 2.5 years.

Capital Expenditure

The project is estimated at $643.8-million.

Planned Start/End Date

The project is expected to take two years to complete.

Latest Developments

European Metals has announced a substantial increase in planned lithium production.

The company said on December 20 that yearly production of battery-grade lithium hydroxide monohydrate had been forecast to reach 41 658 t, a 42% increase from earlier projections.

This output equates to about 36 670 t of battery-grade lithium carbonate. RoM ore production will also rise by 42%, from 2.25-million tonnes a year to 3.2-million tonnes a year.

These enhancements had been achieved without expanding the environmental footprint of the underground mine or altering the processing plant's head grade and recovery rates, the company added.

The expansion aligns with European Metals' commitment to support the EU’s goals of lithium self-sufficiency by 2030.

The increase in RoM production is attributed to a shift in processing to the Prunéřov EPR1 site, which spans 36 ha – 50% larger than the previously designated Dukla site.

Key Contracts, Suppliers and Consultants

Widenbar and Associates (resource estimation); Bara Consulting (mine design and scheduling); Ausenco (front-end comminution and beneficiation); and Hath Associates (lithium carbonate and hydroxide plants).

Contact Details for Project Information

European Metals Holdings, tel + 61 8 6245 2050.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

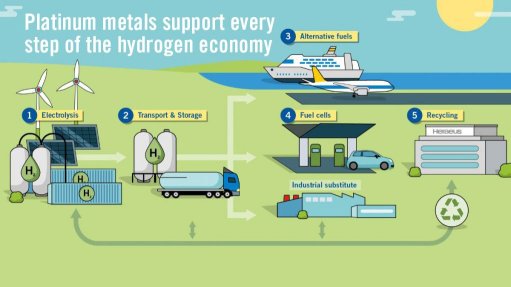

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation