Company launches on-site mechanical seal replacement

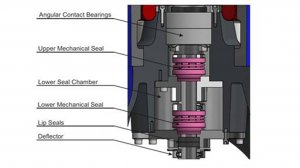

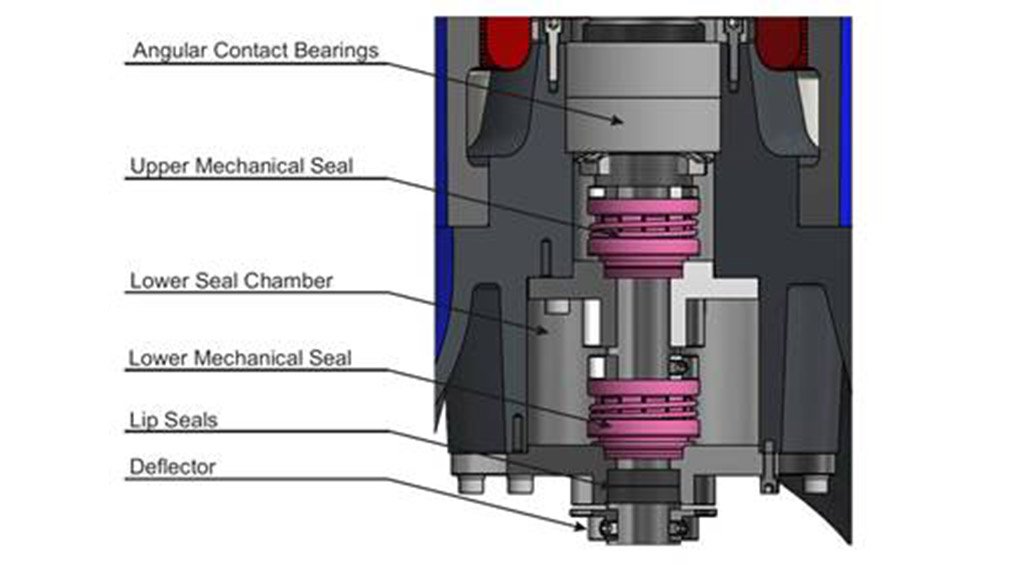

IMPROVING SYSTEMS Hazelton Pumps launched its on-site mechanical seal replacement system for the Hippo slurry pump range

Heavy-duty slurry pumps manufacturer Hazleton Pumps launched its latest innovation, the Hazleton Pumps On-Site Mechanical Seal Replacement System, for its Hippo slurry pumps range used predominantly in mining.

“The system is designed so that the client can replace the mechanical seals of the pump without having to remove the shaft, bearings, electrical stator winding or the pump cables,” says Hazleton Pumps MD Niel Wehmeyer.

He explains that the mechanical seals have a limited life span, compared with the other hard-wearing pump parts. “If it is required that the mechanical seals be replaced on the pump, it can be done on site, resulting in a major savings effect on the total cost of ownership of the pump.”

In most cases, heavy Hippo submersible pumps are used in operations that are in remote areas. Therefore, the cost of removing the pump from an operation, as well as the transportation to a repair location, can be up to 40% of the pump’s repair costs, Wehmeyer points out.

This system also eliminates the extra handling, rigging and transport costs.

Moreover, Wehmeyer believes that the introduction of the system complements the existing safety qualities of the Hippo heavy-duty slurry pumps.

“The pumps can work in hazardous, explosive areas and can be customised to accommodate all voltages and frequencies.”

He explains that the pump is controlled through an electrical switchgear that can be customised to accommodate client requirements.

“It is one of the safest globally, as the protection sensors and transmitters are integrated with the switchgear to ensure that the pump does not lose a winding when in use,” says Wehmeyer.

He concludes that the company is working on new pump developments that will be revealed later this year.

Article Enquiry

Email Article

Save Article

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation