Confectionery company using vacuum pump gripper tech

SUCKING PUMP Suction cups are attached to the vacuum pump which then picks up and placed biscuits into flowpacks at a confectionery production plant

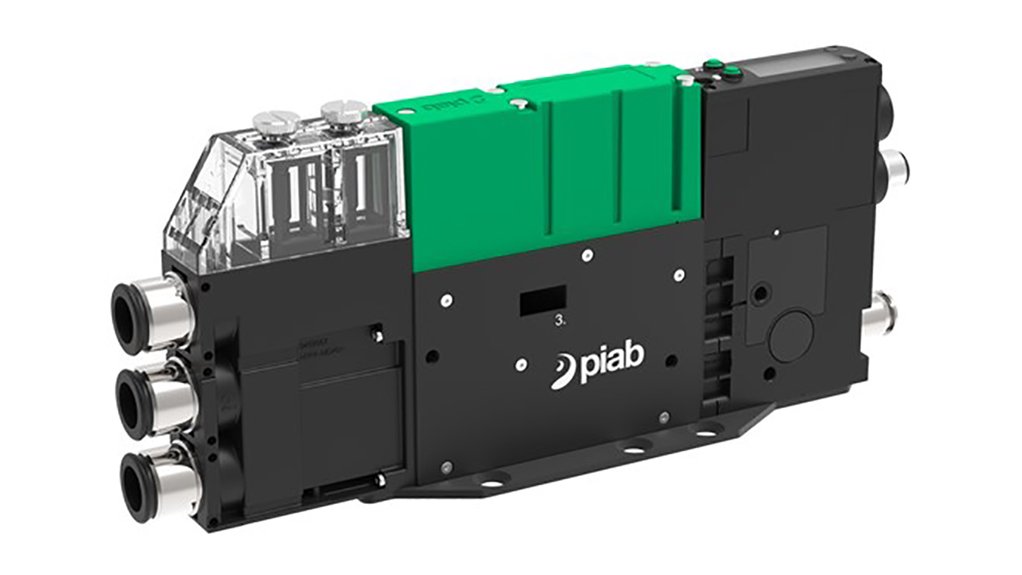

Global packaging system manufacturer Tecno Pack SpA has designed and built grippers able to handle pick-and-place applications in the plant of a leading international confectionery company, using industrial vacuum equipment supplier Piab's piGRIP suction cups and piCOMPACT 23 SMART vacuum pumps.

Tecno Pack SpA's packaging line picks the biscuits and packs them in flowpacks – the primary packaging – and then inserts the flowpacks into a cardboard box, which is the secondary packaging.

The process is characterised by different types of flowpacks containing biscuits, and different carton sizes, which vary according to the size of the flowpacks. Piab solutions are used for the secondary packaging.

To handle these operations, Tecno Pack SpA's plant is equipped with a robot station with four flexpicker robots.

The flowpacks arrive in a disorderly manner on the conveyor belt where they are scanned by a vision system and then picked up in the correct orientation by the robots.

The robots then place the flowpacks on the compartments of a parallel conveyor for insertion into the cardboard box, which is then closed and labelled.

Each robot can use different types of grippers with one or two piGRIP BGI25 suction cups.

The grippers are interchangeable depending on the flowpack formats to be picked.

To reduce downtime for format changes, the grippers feature a quick-release interface.

The grippers are positioned on the wrist of the flexpicker and are light.

The lightness of the flexpicker is owing to the piCOMPACT 23 SMART vacuum pump that drive the grippers being remote-controlled and located on the upper structure of the robot making it much more powerful.

In addition, the vacuum is independent and autonomous: for each gripper with one or two suction cups there is a single pump.

Gripping is carried out one at a time, with multiple releases into the case.

In terms of cycle times, in the robotic area equipped with four robots, 500 flowpacks are picked-up per minute which equates to 125 pieces a minute for every robot.

“The piCOMPACT 23 SMART pump guarantees fast and repetitive pick-up and release times thanks to the integrated control valves and vacuum switches,” says Tecno Pack mechanical project manager Giuseppe Facci, about the performance of the system.

He adds that at the same time, the piGRIP suction cups provide a reliable and secure grip.

“Another big advantage is the modularity of the system and the ability to quickly change grippers according to flowpack format.”

On the cooperation with Piab, Facci says the type of suction cup was specified directly by the client, which only works with premium suppliers.

“As for the vacuum generators, we relied on the advice and experience of authorised Piab distributor F.lli Bono representative Vladimiro Marconato, who guided us in our choice”.

The piGRIP is a unique configurable suction cup concept with individually optimised parts for gripping, lifting and height compensation.

Packaging small bags like the flowpacks in this application into cartons is the specialty of Piab’s piGRIP suction cups that have particularly soft lips to hold on to the changing surface of a bag, allowing for secure and quick moves enabling fast automated processes.

Tecno Breakdown

The piCOMPACT 23 SMART is a configurable vacuum ejector based on COAX technology with integrated controls, developed for robotic handling applications.

It is ideal for medium to large vacuum systems, namely for loading, sorting, transferring, and unloading various materials.

It features an optimised design for maximum reliability, versatility, high flow rates and short cycle times.

Piab’s vacuum generation technology, COAX, minimises energy consumption, while offering a secure and fast grip owing to its high initial vacuum flow.

COAX ejectors are up to twice as fast as other ejectors and deliver three times more flow than a conventional vacuum ejector with identical air consumption.

The pump unit can deliver high performance even with low or fluctuating supply pressure.

This has been proven in independent comparison tests at the Fraunhofer Institute for Machine Tools and Forming Technology IWU in Dresden, Germany.

These tests have shown that the Piab ejectors require significantly lower compressed air to achieve the same output compared to ejectors from other manufacturers, subsequently, reducing the cost of providing compressed air and the total cost of production.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation