Continued need for Vesconite overseas as US pumps industry demand grows

The US pumps industry is showing great demand for wear components supplied by bearings manufacturer Vesconite Bearings, which was recently acknowledged at the 2023 South African Capital Equipment Export Council Exporter of the Year Awards. The company was named exporter of the year in its relevant category.

“This award shows that our locally manufactured products have demand in countries overseas owing to their premium quality and the growing list of benefits enjoyed by customers. It is also indicative of how important it is to form good working relationships with customers. By winning our category, we showcased how well the Vesconite Bearings team has executed this,” says Vesconite chemical engineer Jandri Ueckermann.

Together with the rail and marine industries, the pumps industry is in the top three industries serviced by the company, with Vesconite Bearings attracting the support of international customers in Turkey, Italy and Spain in addition to the US.

“The increased demand from the US is attributed to our materials’ great quality and properties like negligible water swell, continuous low coefficients of friction and the various temperature and chemical ranges that our materials can operate in,” explains Ueckermann.

Developed in 1969 by Vesconite Bearings founder and chemical engineer Alain Leger, Vesconite was first used in underground pumps to replace Ebonite as a piston ring.

In the 1980s, the investigation and development of the material’s applications in pumps was actively pursued in Australia, where VescoPlastics Australia helped a pump operator transition from bronze and asbestos-based bushings to Vesconite. By incorporating Vesconite, a service life longer than the three- to six-months mark was achieved.

The need for bearing materials that could help pump operators realise extended service lives was a driving force for the pump applications Vesconite Bearings offers today.

“The bearing materials that were used in the deep gold mines in the goldfields region in the Free State were exposed to harsh operating conditions. Therefore, the original bronze bearing components specified failed owing to poor lubrication, while the nylon components swelled and seized,” states Ueckermann.

Vesconite was developed to eliminate the need for grease through the material’s internal lubrication and low water swell properties which address the challenges faced in the pumps industry.

Traditional bronze and/or rubber cutlass bearings have limited service lives and also do not support dry-running under normal operating conditions. Larger running clearances are also needed to reduce contact between the bearings and the shaft, resulting in higher noise and vibration levels.

“Vesconite Hilube, our flagship bearing material, has helped pump operators overcome these wear-related and operational challenges by providing them with properties that allow for dry-running up to one minute, smaller running clearances, negligible water swell, a constant low coefficient of friction and internal lubrication. With time, Vesconite Bearings also developed materials suitable for applications with high temperatures and abrasive conditions – HiTemp 150 and HiTemp 160,” elaborates Ueckermann.

HiTemp 160 is the most recent bearing material developed by the company and can operate in conditions of up to 200 °C in steam and is highly resistant to various chemicals.

Vesconite Bearings actively continues to assist with the development of new bearing materials and bearing components to solve challenges in the pumps industry, she says.

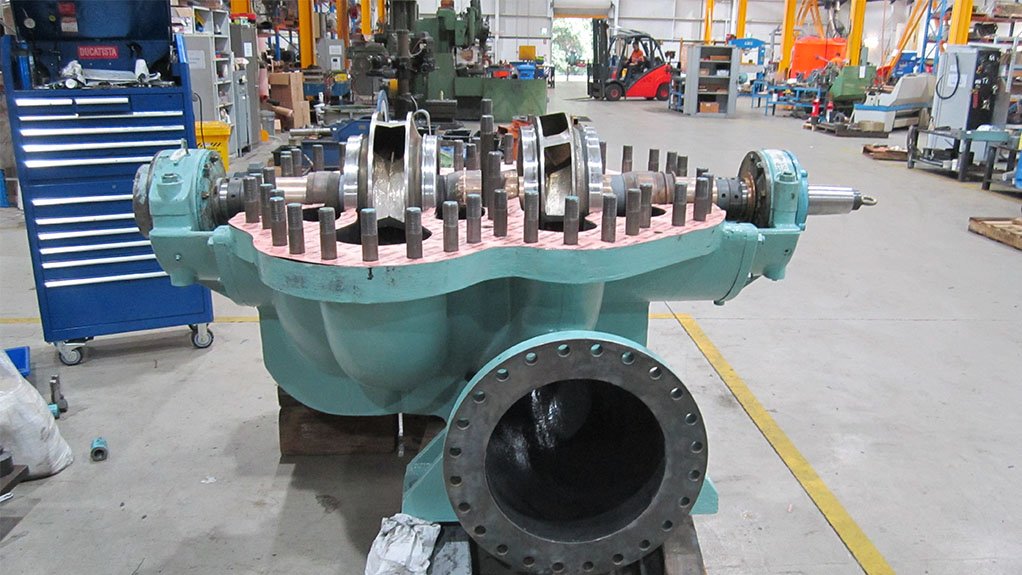

The range of pumps supported by Vesconite Bearings has grown considerably over the years to include sump pumps, multistage surface pumps, submersible pumps, vertical turbine pumps, vane pumps and continues to expand. Vesconite’s materials are used to produce wear components, such as lineshaft bushings, vanes and casing wear rings, for pumps in various industries, including water treatment, irrigation, fertiliser sprayers, food processing, mining and desalination.

All Vesconite Bearings’ components are manufactured in the company’s factory in Virginia, in the Free State, which is supported by a large solar farm for power.

Not only is this investment in solar power expected to supply a third to a half of the facility’s daily power needs, but it will also reduce the carbon footprint of Vesconite Bearings’ production process.

“The factory currently exceeds 15 000 m2 and includes our compounding, moulding, extrusion and machining departments. The factory has more than 100 computer numerically controlled machines that vary from two-axis to five-axis, allowing us to accurately machine a large variety of bearings, including unconventional or complex shapes in shorter times,” explains Ueckermann.

Accordingly, Vesconite Bearings says it has no problem supplying customers in dozens of industries worldwide with its bearing components. The company also assists its customers in the best time frames possible by keeping stock of the bearing components they procure regularly, she concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation