Delba Electrical: Your preferred service partner

Delba Electrical is a renowned company that specializes in the refurbishment of electrical rotating machines. For six decades, Delba has been at the forefront of repairing electric rotating equipment, earning a reputation as one of the industry's most trusted and reliable service providers. Delba Electrical is a state-of-the-art facility that comprises four main divisions consisting of large machines (MV, HV and DC), power generation, small machines (LV up to 1 000 V) and field services.

It also includes support services for copper extrusion, conductor covering, coil manufacturing, a machine shop and a boiler shop.

With a rich history dating back 60 years, Delba has consistently set the industry standard for excellence and reliability in electrical rotating machine repairs. Our team of highly skilled employees are experts in breathing new life into generators, motors and other rotating electrical equipment. Delba Electricals’ commitment to quality, precision and cutting-edge technology ensures that our clients receive refurbished machines that perform at optimal efficiency.

Over the years, we have earned a stellar reputation for our unwavering dedication to customer satisfaction and our ability to extend the operational lifespan of electrical rotating machinery. Delba Electrical stands as a trusted partner for businesses seeking to maximise the longevity and performance of their critical electrical assets.

Delba Electrical has embarked on a few expansion projects through the years in order to meet growing customer and market demands. These expansion projects are aimed at expanding production capabilities, improving the production process and quality of our products and services. Presently, Delba stands as a beacon of expertise, offering comprehensive repair solutions for electric motors, generators, pumps and other rotating equipment.

Delba Electrical offers extensive modern world class facilities including:

- The largest and newest Vacuum Pressure Impregnation facility in Africa (4 m diameter and 4.5 m deep).

- 100 t overhead crane with dual hook lifting capacity.

- Two continuous copper conductor extrusion machines.

- Nine lines of continuous copper conductor insulation covering machines.

- Coil manufacturing facility including loop winders, edge benders, coil spreaders, taping machines and coil consolidation press, in a dedicated positive pressure clean working room.

- Gas fired curing and baking oven with PLC control and temperature monitoring (4 m x 4 m x 4 m).

- Gas fired pyrolytic burn-off oven with PLC control, temperature monitoring and instantaneous flame-up quenching system.

- Rotor dynamic balancing (up to 4 t in-house).

- Balancing above 4 t, including high speed vacuum chamber (done by Siemens through our mutual channel partner agreement.)

- Spray-painting booth (8 m x 8 m x 8 m).

- State of the art fixed and portable test equipment.

- Fully equipped machine shop and boiler shop conducting in-house manufacturing of replacement parts.

Delba's success can be attributed to its unwavering dedication to quality and its highly skilled team of employees. Delba has always recognised the critical role that electric rotating equipment plays in numerous industrial processes, and thus has made it our mission to provide excellent repair services to keep these systems running efficiently.

Looking ahead, Delba remains committed to pushing the boundaries of repair services for electric rotating equipment. With the growing demand for sustainable solutions, Delba has ventured into the realm of energy-efficient motor repairs and retrofits, helping clients reduce their carbon footprint and improve energy efficiency. Delba's forward-thinking approach ensures that it stays ahead of industry trends and continues to provide innovative solutions to its clients' evolving needs.

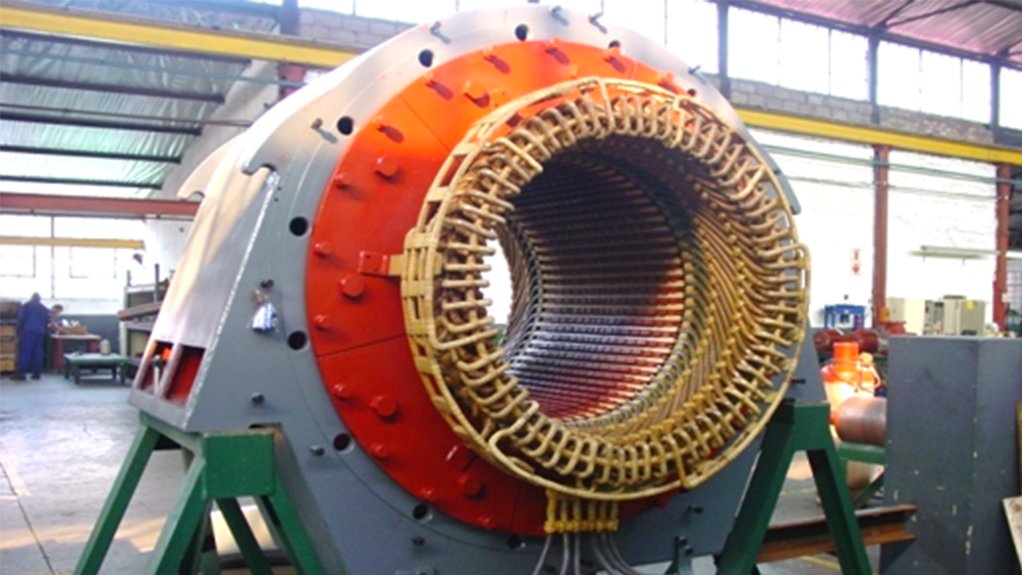

Power Generation:

The company’s journey into power generation has been one of growth, excellence and a relentless pursuit of customer satisfaction. With our focus on quality, innovation and service, Delba is poised to continue its legacy as a premier repairer of power generation equipment for many years to come.

Our generator specialists have an average of 20 years of experience in the generator repair field and were trained in the Eskom environment since the early 1980’s specialising in the repair and complete rewinds of generators up to 900 MW.

One of Delba's primary repair capabilities is generator rotor and stator overhauls and rewinds. Our repair services also include upgrades and design modifications. These overhauls are designed to extend the life of the generators and improve its performance, reliability and efficiency.

Our team of technicians has the knowledge and expertise to troubleshoot and repair complex generator issues, ensuring that your power generation equipment operates smoothly and efficiently.

Delba’s power generation services include minor and major repairs on various designs or types of generator stators and rotors, including:

- General overhauls of any design or type of generator stator or rotor.

- Complete rewinding of generator rotors and stators.

- Modifications of generators including, but not limited to:

- Upgrading of rotor and stator insulation systems and coil retaining rings.

- Improvements on rotor and stator cooling systems.

- Modifying rotor windings, rotor slip-rings and rotor shafts.

- Replacement of rotor and stator wedges.

- Minor and major repairs on any design or type of exciter stator or rotor.

- Complete rewinding of exciter rotors and stators.

Delba provides exceptional repair services that improve the reliability, performance and efficiency of power generation equipment.

Cas Sulaiman

COO - Power Generation

Mobile: 076 820 5233

E-mail: cass@delba.co.za

Danie Janse van Vuuren

Business Development & Field Service Manager

Mobile: 082 349 0097

E-mail: daniej@delba.co.za

Dirk van Vuuren

Sales Manager

Mobile: 082 563 2338

E-mail: dirk@delba.co.za

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation