Diamond evaluation sampling progressing at Botswana BK16 project

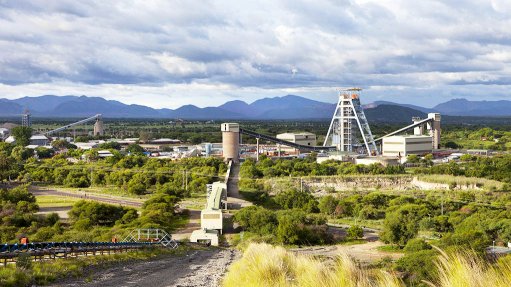

SAMPLING SORTED Tsodilo Resources has completed processing of all the large diameter drilling samples through its dense media separation plant

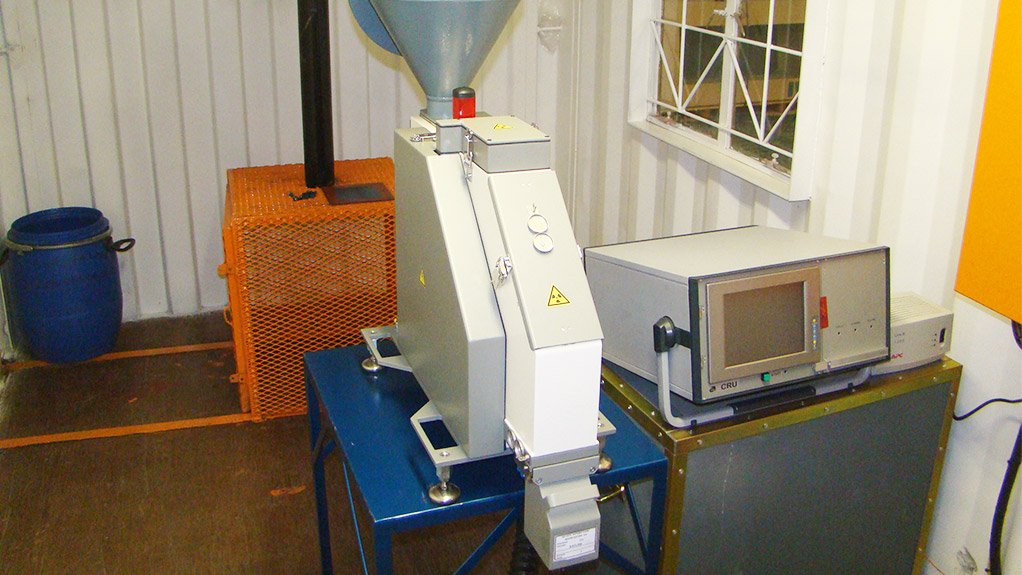

SORTING MACHINE The BV Polus-M X-ray is used to prepare the X-ray concentrate for hand sorting

Some 101 diamonds (18.57 cts), the largest of which was 1.38 ct, were recovered last month from the treatment of the first evaluation samples taken from the BK16 kimberlite pipe, which forms part of the Orapa kimberlite field, in Botswana.

Diamond explorer Tsodilo Resources’ (Tsodilo) sampling programme involves large diameter drilling (LDD); the processing and concentrating of the LDD samples in its dense-media separation (DMS) treatment plant; sorting the DMS concentrate through an X-ray recovery unit; and, hand-picking those concentrates to recover these stones.

“The 101 stones which were recovered from the first samples still have to be acid-cleaned but it appears that their quality is similar to those that we obtained in 2016, which were mainly D, E and F colour gemstones. Like the 2016 parcel, there are no brown or yellow stones in this parcel,” says Tsodilo COO and president Mike de Wit.

“It also turned out that about 8% of the 2016 stones were Type IIa diamonds, which, against a background of a global average of about 2%, indicates a higher-than-normal proportion of Type IIa stones.”

The company has completed processing of all the LDD samples through its DMS plant and is presently sorting those concentrates using a Bourevestnik (BV) Polus-M X-ray recovery unit. This process will take place until early June.

“The exploration company has almost completed the processing of selected LDD tailings samples through the DMS plant for auditing purposes. This it will use to assess the efficiency of the plant and to ensure that all the diamonds are recovered. Those tailings concentrate samples have also been transferred to the BV X-ray sorter.”

The company purchased the BV Polus-M X-ray sorting unit from Russian manufacturer Bourevestnik, and is used to efficiently reduce the DMS concentrate and prepare the X-ray concentrate for hand sorting. “At the X-ray sorter, the material is dried and classified into three fractions: 1 mm to 3 mm, 3 mm to 8 mm, and 8 mm to 12 mm. These various fractions are then fed into the BV Polus-M X-ray separately. The concentrates of the different fractions are hand-sorted in a glove box where the stones are picked and weighed,” explains De Wit. Tsodilo will also be recrushing the +3 mm and +8 mm BV X-ray concentrates to liberate any diamonds that might still be locked up in the kimberlite.

De Wit says the LDD programme comprised 14 holes and each hole was subdivided into 12 m slots. Each slot represented one sample. As the samples came out of the drill holes, they were screened through a shaking unit to +1 mm at the drill site. The +1 mm material was taken to the DMS plant, in Letlhakane, where it was crushed, screened and concentrated to +1 mm to –12 mm material. In total, there were 243 LDD samples to process.

In these samples, the company hopes to discover Type IIa diamonds, which, according to De Wit, have no or very low nitrogen content, and are therefore generally “pure and high-value stones”.

De Wit highlights the importance of avoiding the breaking of diamonds because this reduces their sizes and, hence, negatively affects their value. The company, being conscious of this risk, was therefore careful during the LDD programme, with a geologist positioned at the drill 24/7 to monitor conditions, such as the penetration rate, the state of the drill bit, and do the screening analyses on all drill samples to assess the coarseness of the drill chips and not grind the kimberlite, and the diamonds, to pulp. In some samples, large chunks of kimberlite up to 10 cm in size were recovered.

According to De Wit, this ensured that there was minimal breakage during the drilling phase. “With respect to processing the samples through the plant, we have been careful in reducing the percussion of the material through the various parts of the plant to a minimum. “Once the diamonds have been acid-cleaned, we will have the diamonds valued and studied, particularly in terms of breakages and this will tell us what the effect the drilling and processing phases had on the stones.”

An experienced geoscientist will be contracted to study the diamonds and will be able to tell whether a diamond is broken in the kimberlite by geological processes or if the breakage is due to the extraction and/or treatment processes of the samples.

Tsodilo currently employs about 30 people at this project. The LDD was outsourced and the treatment of the material through the plant, which the company owns, was overseen by a contract consulting metallurgist. The Tsodilo team includes four young Botswana geologists. The expat personnel that the company employs comprise a chief geologist, a geophysicist and an artisan. The remaining personnel are all Botswana citizens.

“As a junior company, we have learned to run our programmes tightly and have been training citizens for many of the jobs on our drill rigs, the DMS plant and the BV recovery units as well as doing our own geophysical surveys,” adds De Wit.

Following the completion of the sampling programme and depending on the results, Tsodilo may proceed to a feasibility stage as a next step, therefore the market value for the diamonds is going to be very important. “If the evaluation phase currently under way is positive in terms of diamond value and grade, we will have to proceed to the next phase and recover additional diamonds to have sufficient stones for valuation purposes for a feasibility study. “This will take us into 2019 and it will therefore be necessary to renew the prospecting licence next year.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation