Experience-driven innovation powers cementation Africa’s underground solutions

From initial development to operational readiness, Cementation Africa plays a pivotal role in helping mines transition smoothly into full production

With a strong foundation built on experience, Cementation Africa continues to evolve its contracting model to meet the shifting demands of modern mining

Proactive safety innovations introduced by Cementation Africa have set new standards for underground mining environments across the continent

By embedding digital tools and mechanised systems into its operations, Cementation Africa enhances both site safety and operational output

A culture of accountability and care underpins Cementation Africa’s impressive track record of millions of hours worked without serious incident

Each project undertaken by Cementation Africa reflects a long-term view, blending engineering precision with social upliftment in host communities

This article has been supplied.

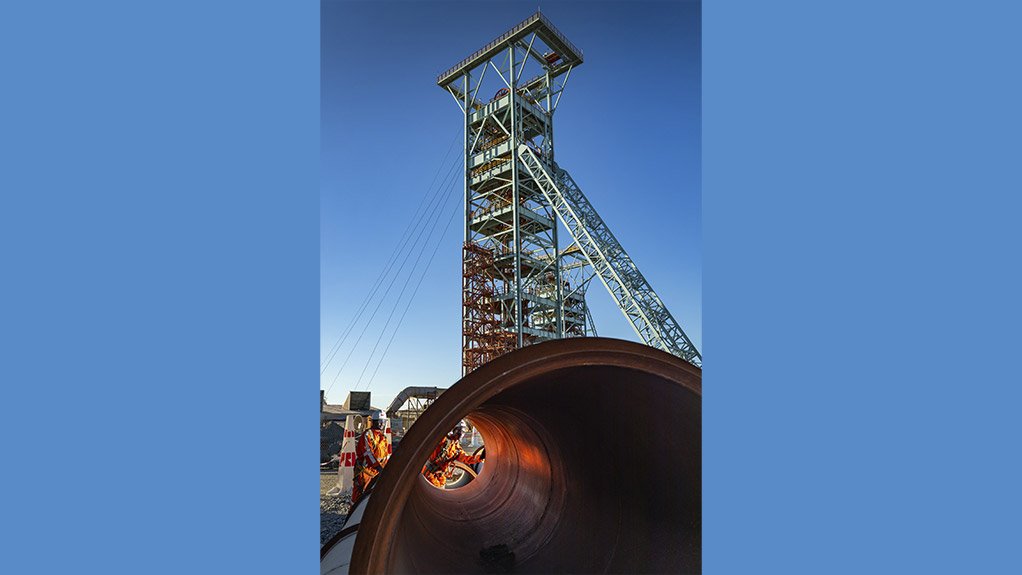

Innovation in challenging mining applications such as shaft sinking and mine development stems not only from experience and institutional knowledge but is also driven by close client partnerships built on trust and confidence.

Graham Chamberlain, New Business Director at Cementation Africa (previously known as Murray & Roberts Cementation), emphasises that the company’s brand and reputation have always been built on successfully delivering quality projects under demanding conditions.

Formed through the merger of Murray & Roberts RUC and The Cementation Company (Africa), the company marks its 21st year with a new chapter as it becomes Cementation Africa from 1 July 2025, following its acquisition by a consortium of investors led by Differential Capital. While the name changes, Chamberlain affirms that the team remains fully committed to providing the same high performance underground mining solutions as it embraces this exciting new phase.

“Our many years in the mining industry, where we work on complex and lengthy projects, have taught us that collaboration is always the most effective way to overcome the challenges that every project presents,” says Chamberlain. “It is often through these close working relationships that innovative solutions emerge, keeping us at the forefront of safety and productivity in underground mining.”

He notes that understanding and mitigating risk lies at the core of the company’s work, whether developing shafts, constructing underground infrastructure or undertaking strategic rehabilitation of critical elements like ore passes. Much of this success, he explains, is driven by applying proven technologies and equipment in new ways - a capability that has become increasingly valuable amid the decline of research capacity within the local mining sector.

“We combine our rockface knowledge with a deep understanding of the tools and equipment we use, allowing us to imagine and share ideas on how these technologies can be advanced and improved,” he explains. “This makes us valuable partners to original equipment manufacturers (OEMs), with whom we collaborate closely to enhance safety and efficiency across our operations.”

This approach is especially important given that every project presents a unique combination of factors - from natural ground conditions to corporate culture and operating environment. These variables require tailored solutions, reinforcing the need for collaboration, adaptability and innovation at every stage.

“Within each specific scenario, there are invariably unexpected aspects that arise and it is the ability to deal constructively with these ‘curve balls’ that makes for successful projects,” he notes. “No mining project is ever plain sailing and that’s where our experience becomes invaluable – as there are always lessons from past projects that help guide the way forward in a structured and positive manner.”

Among the many advances in best practice is the integration of directional drilling into the raiseboring process, significantly improving accuracy, reducing risk and providing greater financial predictability. On a South African platinum project, for example, the company successfully drilled a 950 m pilot hole to intersect with horizontal development, achieving an exceptional deviation of just 0.05% or 500 mm off centre.

Safety has also been elevated through the use of remote shotcrete lining technology for shaft concrete lining, which removes workers from high risk contact areas and enhances overall operational safety.

“We have significantly evolved the way we use drill rigs in our shaft sinking operations,” he notes. “For many years, foot-mounted drill rigs were the standard; but in our drive to remove people from hazardous, high-energy zones, we now suspend the drill rigs beneath the shaft-sinking stage.”

These rigs have progressed from pneumatic and hydraulic models to fully electro-hydraulic systems in the Cementation Africa fleet, now in its fourth generation of technological development and equipped with a host of safety and efficiency features. Mucking has also seen significant innovation, contributing to the company’s exceptional safety performance - highlighted earlier this year by the achievement of 8 Million Fatality Free shifts across its shaft sinking and related projects.

“Traditionally, the cactus grab was a common tool for mucking blasted material from a shaft bottom,” he explains. “However, our safety analyses over the years made it clear that we needed a safer alternative to this – as well as to the over-shoulder loader.”

The solution was found in adapting the well-established hydraulic excavator design, with the arm and bucket mounted to the bottom of the stage and operated remotely to enhance safety. In addition, the pneumatically operated Brutus clamshell mucker - widely used in North America - was introduced by Cementation Africa into common use in southern Africa.

The company continues to share knowledge and best practices with its sister operations, Cementation in Canada and the US, strengthening its innovation capacity through global collaboration.

An essential aspect of shaft sinking and mine development is the concrete used to line shafts, haulages, and other critical mine infrastructure. Chamberlain highlights that advancements in cement and concrete technologies, along with improved methods of material transfer, have been effectively harnessed to enhance performance, safety and efficiency on site.

“While ordinary Portland cement was used in earlier days, we have taken full advantage of the many scientific advances in the cement industry, including admixtures and plasticisers, to achieve superior results in the placement and final strength of concrete,” he says. “Even our placement methodologies have evolved significantly, with the use of receptacles now replacing traditional slick-lines for improved efficiency and control.”

While slick-lines were once seen as a quick and simple method for transferring concrete, they often caused separation of the concrete’s components, requiring remixing in a kettle at the destination level before application. Today, this issue is effectively addressed through the use of modified kibbles, which maintain the integrity of the concrete mix even at depth.

“As we apply these innovations across Africa, we are also seeing our partner OEMs expanding their regional presence to align with national expectations for in-country service delivery,” he says. “Our strategy has been to establish regional hubs that bring solutions closer to our customers, while also reducing the complexities of cross-border logistics and administration.

“Over time, building trust with clients leads to relationships where Cementation Africa is given insight into the ‘full picture’ of an upcoming project,” he says. “This allows us to contribute meaningful input at an early stage, supporting the client’s vision and planning from the outset.”

“This is where our experience and innovation add real value to a mining project,” says Chamberlain. “It allows us to engage in a two-way conversation with the client to identify the safest and most efficient solutions for the medium to long term.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation