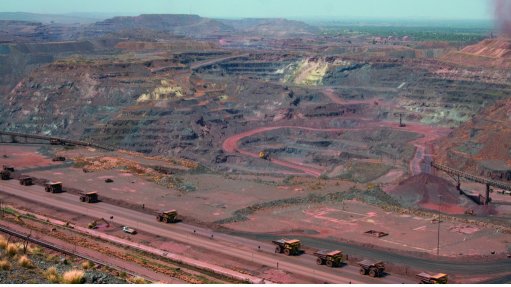

Florence Copper in situ copper recovery facility, US – update

Photo by Taseko Mines

Name of the Project

Florence Copper in situ copper recovery (ISCR) facility.

Location

Arizona, in the US.

Project Owner/s

Florence Copper Incorporated, a wholly owned subsidiary of midtier copper producer Taseko Mines.

Project Description

The Florence deposit contains 2.5-billion pounds of copper in 345-million tons of probable reserves.

The project proposes to build and operate the Florence Copper ISCR facility, and produce 85-million pounds a year of copper over the 22-year life-of-mine (LoM). Total LoM production is estimated at 1.5-million pounds of copper.

ISCR is an extraction method used for selected mineral deposit conditions as an alternative to openpit or underground mining methods.

ISCR extracts copper by injecting a weak sulphuric acid solution, referred to as raffinate, through targeted portions of the mineral deposit using an array of injection wells. The raffinate passes through natural fractures and voids in the deposit and dissolves the copper mineralisation.

The copper laden solution, known as pregnant leach solution (PLS), is collected in recovery wells where it is pumped to the surface for processing. Copper is extracted from the PLS using solvent extraction and electrowinning (SX/EW) techniques producing a saleable copper cathode product.

Potential Job Creation

As of January 15, 2025, about 290 construction and support personnel were on site.

Net Present Value/Internal Rate of Return

The project has an after-tax net present value, at a 8% discount rate, of $930-million and an internal rate of return of 47%, with a payback of 2.6 years.

Capital Expenditure

The project has an initial capital expenditure of $232-million.

Planned Start /End Date

Commercial production is expected to start in 2025.

Latest Developments

The project has surpassed the halfway mark and remains on track for first production by the end of 2025.

Providing a construction update on January 15, Taseko stated that, as of December 31, overall project completion reached 56%.

Construction activities are advancing on schedule, with nearly 450 000 project hours logged without any reportable injuries or environmental incidents.

Key fourth-quarter milestones include the completion of process ponds and the surface water run-off pond, alongside the placement and welding of SX settler and launder modules.

Seventeen production wells were fully built during the quarter, bringing the total to 51 of the planned 90 wells.

The main pipe corridor from the wellfield to the process plant is nearly complete, and installation of high-density polyethylene piping is ongoing.

Field-erected process and service tanks are under construction, while mechanical and piping installations have progressed throughout the SX/EW. The structural steel erection for the SX pipe rack is nearing completion, with piping installation and electrical work under way.

Further, the water treatment building has been erected, and preparations are in progress for the electrowinning building.

Taseko president and CEO Stuart McDonald has said that costs remain in line with guidance.

Key Contracts, Suppliers and Consultants

None stated.

Contact Details for Project Information

Taseko Mines, tel +1 778 373 4533 or email investor@tasekomines.com.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation