FLS Training Academy strengthens Africa’s mining skills base through NAMB Accreditation

The FLS Training Academy in Chloorkop continues to expand its capabilities to support artisan and engineering skills development for the mining sector

Recent NAMB accreditation positions the FLS Training Academy as a recognised assessment centre for essential artisan trade testing

The FLS Training Academy trains, assesses and qualifies fitters, turners and fitter-and-turners for FLS and industry partners

Years of dedicated investment have established the FLS Training Academy as a regional hub of technical excellence

Since 2018, the FLS Training Academy has become central to the company’s strategy to grow a skilled and diverse technical workforce

With more than half of its learners being women, the FLS Training Academy is driving diversity and empowerment in mining-related trades

The FLS Training Academy in Chloorkop hosts up to 90 learners at a time, offering programmes ranging from apprenticeships to graduate development

Practical training across workshop, machining and field service environments at the FLS Training Academy ensures apprentices gain real-world technical experience

The FLS Training Academy’s growing global linkages are creating new opportunities for learners to support FLS operations worldwide

The FLS Training Academy’s structured development programmes ensure learners are equipped with the skills needed for long-term careers in the mining and industrial sectors

This article has been supplied.

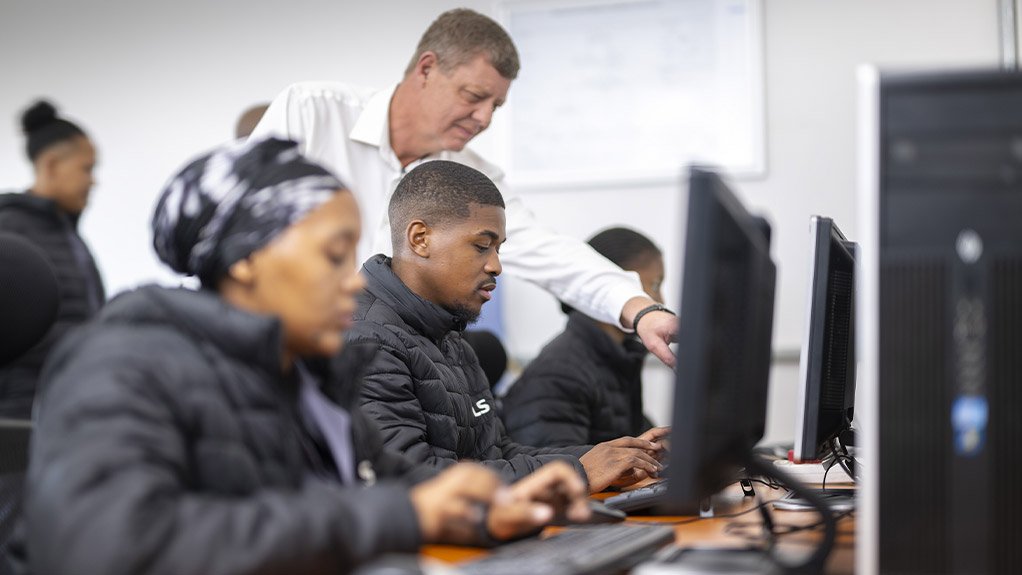

From apprentices to graduate engineers, the FLS Training Academy in Chloorkop, Gauteng, has been building its capabilities and linkages to strengthen the mining sector’s skills base - not only in South Africa but across Africa and the globe.

Demonstrating FLS’s commitment to skills development is the facility’s recent accreditation by the National Artisan Moderation Body (NAMB) as an official assessment centre for artisan testing. According to Steve Parkinson, Head of the FLS Training Academy, this has been another important step in its mandate to “develop exceptional skills in Africa for Africa”.

“This accreditation allows us to conduct full testing for three vital trade categories: fitters, turners and fitter-and-turners,” Parkinson explains. “It means we can now train, assess and qualify both FLS apprentices and those from other companies in the region, creating a regional hub of technical excellence.”

He notes that this status positions the FLS Training Academy as a key player in training and qualifying artisans for the mining and minerals sector - not only within FLS but across the broader industry. The outcome is the culmination of years of focused investment in technical capability and educational quality.

Established in 2018, the FLS Training Academy has become central to the company’s business strategy and a cornerstone of its social responsibility commitments. Beyond producing a pipeline of skilled artisans, the well-equipped facility supports FLS’s goal of maintaining its BBBEE Level 1 status and advancing its Women in Mining initiative.

“We are proud that over half of our learners are women,” he says. “It is part of our commitment to diversity and empowerment, ensuring that technical careers - especially in traditionally male dominated industries like mining - are accessible and attractive to everyone.”

In 2025, for example, 33 of the 61 students were women and a majority of the total were from historically disadvantaged backgrounds. At any given time, the Chloorkop facility hosts between 60 and 90 learners, offering a wide range of programmes - from apprenticeships and learnerships to graduate internships, employee development and customer training.

“Our technical apprenticeships focus on trades such as mechanical fitting and metal machining, providing practical, real-world experience across the FLS workshop, machining and field services departments,” Parkinson says. “Learners spend their first 11 months at the facility gaining foundational skills before moving into operational environments.”

Partnerships also play a key role in the FLS Training Academy’s impact, he explains. For instance, it collaborates with private vocational training college Sol-Tech, hosting millwright apprentices for practical field experience. The facility’s two-year commercial apprenticeships - known as learnerships in South Africa - include specialisations in supply chain, information technology, business administration and health and safety.

“Our apprentice programme has become well recognised within FLS, to the extent that we have been requested to assist other regions with their apprenticeship programmes,” he says. “There is also scope to deploy our apprentices in other FLS service centres globally, as and when required.”

Wherever possible, the latest digital technologies are leveraged to enhance the learning experience, including ‘virtual reality welding’ through sophisticated equipment that records results as if a conventional welder were being used.

The FLS Training Academy is also making advances in the professional registration of graduate engineers. Collaboration is ongoing with the Engineering Council of South Africa to become an accredited training facility for the development of professional engineers.

“We have already designed a development programme and logbook for this purpose,” he says. “Our aim is to ensure that graduates receive systematic support for their engineering careers in the mining industry – but also for general industry.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation